Chitosan oligosaccharide/cassava starch composite zinc propionate solid and preparation method thereof

A technology of oligomeric chitosan and compound zinc propionate, which is applied in the field of feed, can solve the problems of reducing the balance effect of the overall additive, the anti-mildew effect can not meet the application requirements, and the anti-mildew effect is reduced, so as to increase the stability of the anti-mildew effect. , Improve the effective time of mildew prevention and improve the effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

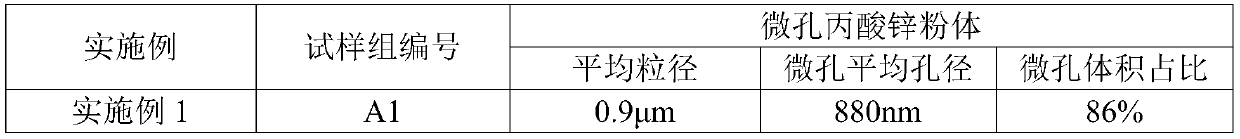

[0030] Embodiment 1: the preparation of chitosan oligosaccharide / tapioca starch composite zinc propionate solid

[0031] 1. Preparation of chitosan oligosaccharides

[0032] According to the ratio of parts by weight, 100 parts by weight of chitosan was added to 180 parts by weight of 0.35mol / L citric acid, after 45°C insulation for 30min, ultrasonic treatment at 65°C for 60min, the ultrasonic frequency was 300kHz; after cooling to 30°C , adding a hydrogen peroxide solution with a concentration of 0.35mol / L to adjust the pH to 7; concentrate and suction filter at a temperature of 2°C, use acetone to separate out the precipitate, and dry the precipitate at 80°C to obtain oligomeric chitosan; For example, 100 parts by weight of chitosan oligosaccharide was added to 250 parts by weight of absolute ethanol, centrifuged for 10 minutes to prepare a chitosan oligosaccharide solution, and stored at 4°C for use.

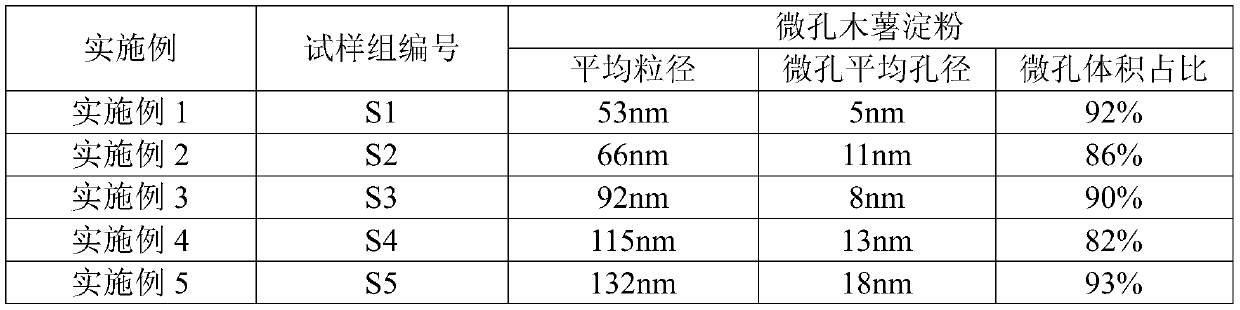

[0033] 2. Preparation of Microporous Tapioca Starch

[0034] According ...

Embodiment 2

[0046] Embodiment 2: the preparation of chitosan oligosaccharide / tapioca composite zinc propionate solid

[0047] 1. Preparation of chitosan oligosaccharides

[0048] According to the ratio of parts by weight, 100 parts by weight of chitosan is added to 250 parts by weight of 0.35mol / L citric acid, after 30 minutes of heat preservation at 45°C, ultrasonic treatment at 65°C for 60 minutes at an ultrasonic frequency of 300kHz; after cooling to 30°C , adding a hydrogen peroxide solution with a concentration of 0.35mol / L to adjust the pH to 7; concentrate and suction filter at a temperature of 2°C, use acetone to separate out the precipitate, and dry the precipitate at 80°C to obtain oligomeric chitosan; For example, 100 parts by weight of chitosan oligosaccharide was added to 250 parts by weight of absolute ethanol, centrifuged for 10 minutes to prepare a chitosan oligosaccharide solution, and stored at 4°C for use.

[0049] 2. Preparation of Microporous Tapioca Starch

[0050]...

Embodiment 3

[0062] Embodiment 3: the preparation of chitosan oligosaccharide / tapioca composite zinc propionate solid

[0063] 1. Preparation of chitosan oligosaccharides

[0064] According to the ratio of parts by weight, 100 parts by weight of chitosan is added to 290 parts by weight of 0.35mol / L citric acid, after 30 minutes of heat preservation at 45°C, ultrasonic treatment at 65°C for 60 minutes at an ultrasonic frequency of 300kHz; after cooling to 30°C , adding a hydrogen peroxide solution with a concentration of 0.35mol / L to adjust the pH to 7; concentrate and suction filter at a temperature of 2°C, use acetone to separate out the precipitate, and dry the precipitate at 80°C to obtain oligomeric chitosan; For example, 100 parts by weight of chitosan oligosaccharide was added to 250 parts by weight of absolute ethanol, centrifuged for 10 minutes to prepare a chitosan oligosaccharide solution, and stored at 4°C for use.

[0065] 2. Preparation of Microporous Tapioca Starch

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com