Polishing pad finishing device

A dressing device, polishing pad technology, applied in abrasive surface conditioning devices, grinding/polishing equipment, parts of grinding machine tools, etc., can solve the problems of influence, difficult continuous dressing of grinding pads, poor process reproducibility and dispersion, etc. , to achieve the effect of improving uniformity, ensuring reproducibility and dispersion, and improving reproducibility and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

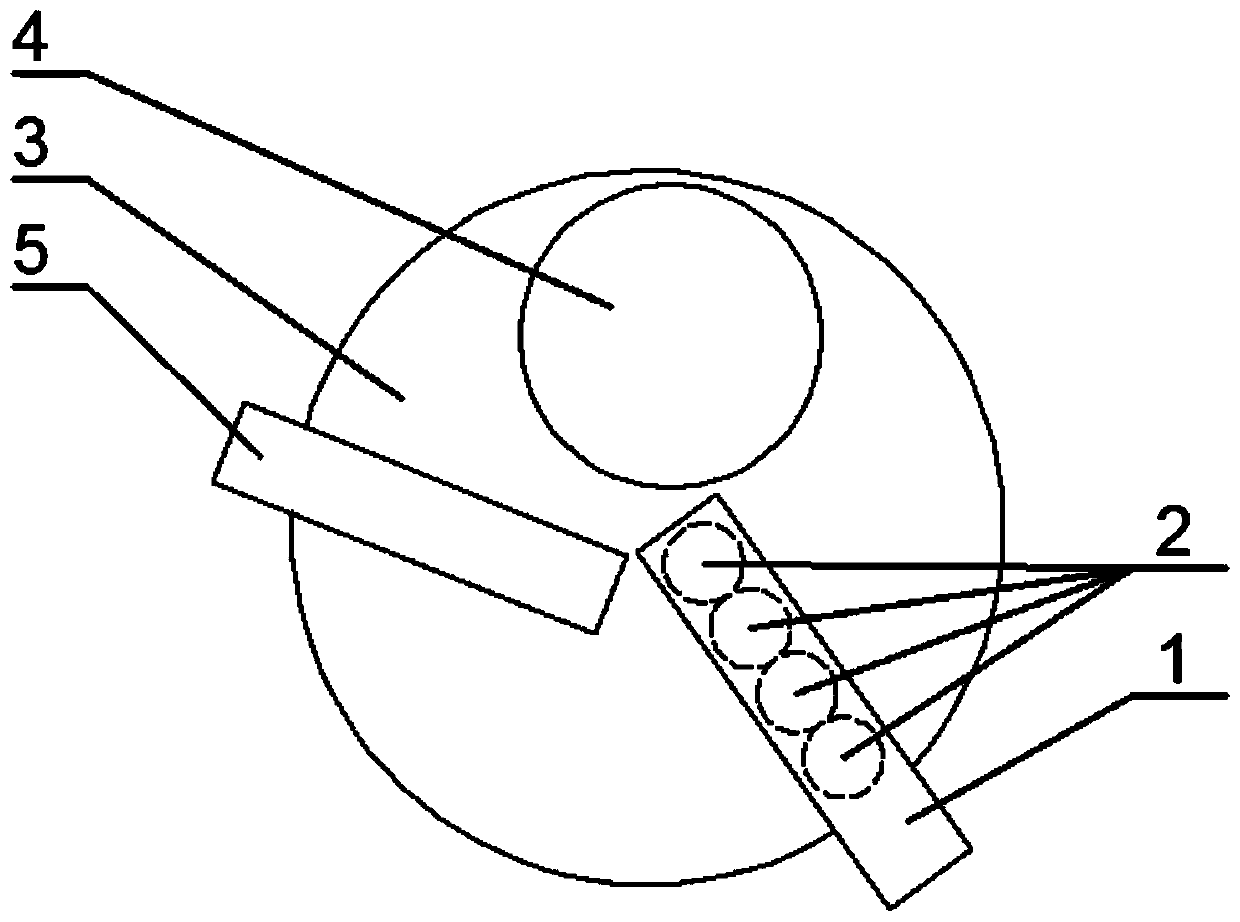

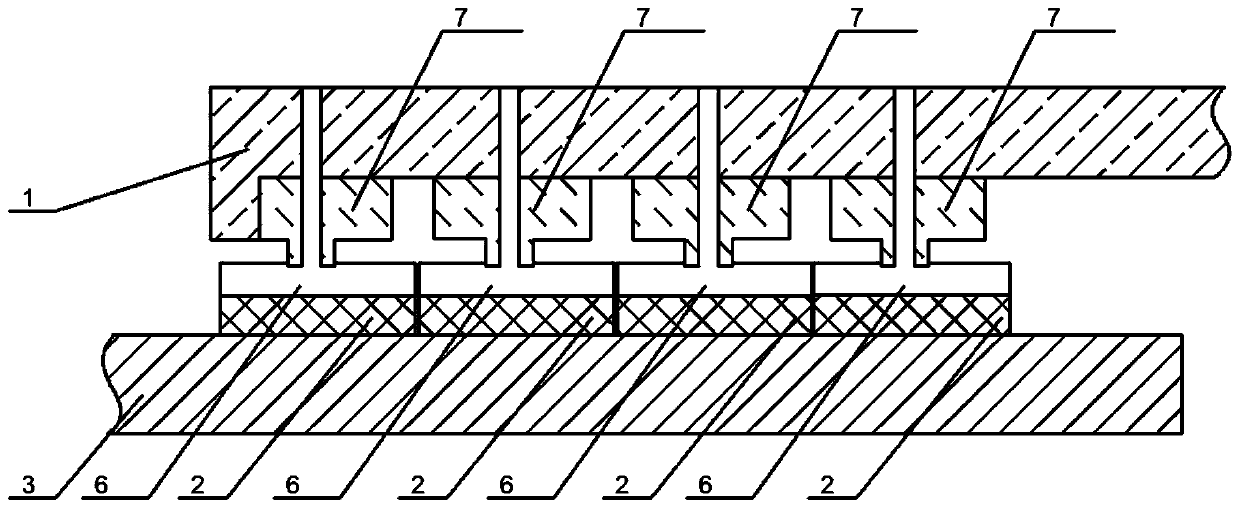

[0034] Install four trimming discs on the adjusting arm, the sum of the diameters of the four trimming discs is equal to or slightly smaller than the radius of the grinding pad, and the four trimming discs are arranged linearly on the adjusting arm, so that when the adjusting arm When pointed at the center of the pad, the four conditioning discs completely cover one radius of the pad.

[0035] The four trimming discs are driven and connected to the four rotating drive mechanisms one by one, and the rotating drive mechanism can use a motor, so that each motor drives a trimming disc to rotate, and the four trimming discs are driven by four motors, and each motor is designed By setting different rotation parameters, each dressing disc can be driven to rotate with different rotation parameters.

[0036]The four trimming discs are driven and connected to the four gas pressurizing mechanisms one by one. The gas pressurizing mechanism can use pneumatic diaphragms. In this way, each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com