Method for reducing melting settlement deformation of permafrost region during highway operation

A technology for permafrost areas and highways, which is applied in the directions of roads, roads, climate change adaptation, etc., can solve the problems of uneven deformation of the road surface, lack of vertical force of continuous horizontal reinforcement elements, and uneven downward movement of the upper limit of permafrost. Achieve the effect of eliminating repair costs, reducing road operating costs, and ensuring high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

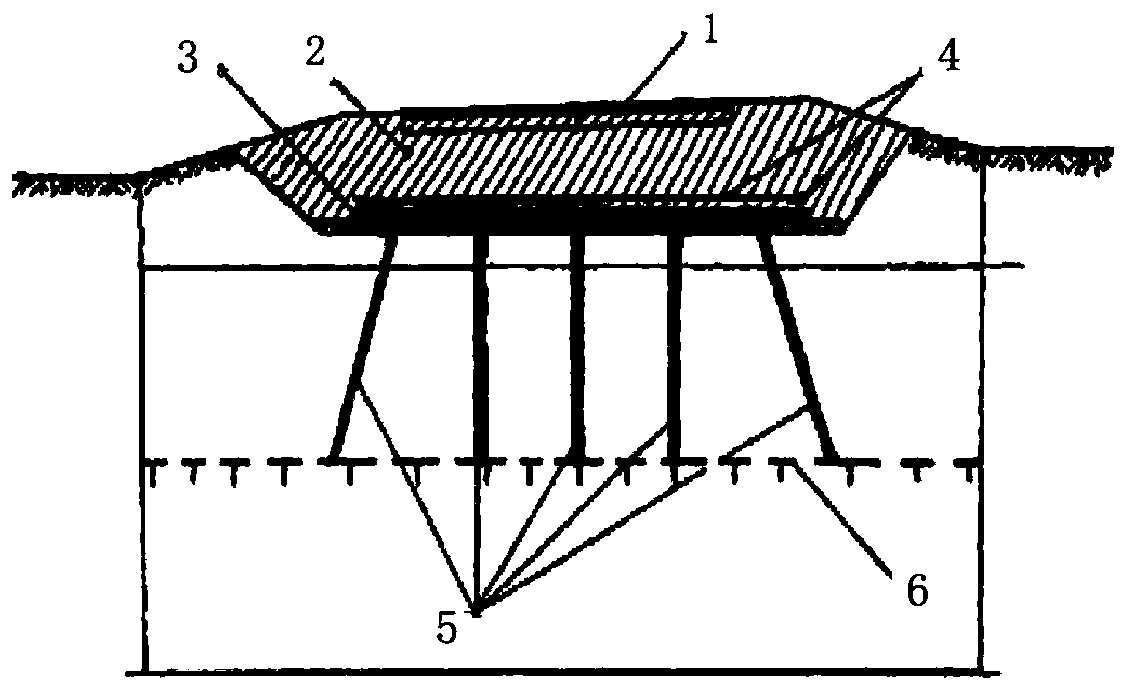

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, a method for reducing thawing and settlement deformation during highway operation in permafrost regions in this embodiment is specifically carried out in the following steps:

[0016] 1. Excavate the natural soil to obtain road cuttings;

[0017] 2. Between the bottom of the cutting and the upper limit position 6 of the permafrost layer, the drilling construction is carried out with a square grid; the drilling construction includes vertical drilling and inclined drilling, and inclined drilling is set on both sides along the direction of the road. Set vertical drilling;

[0018] 3. Put steel sleeves into the vertical borehole and the inclined borehole respectively, fill the lower part of the steel sleeve with sand, and fill the upper part with concrete to form the pile body 5;

[0019] 4. Backfill a layer of gravel buffer layer 3 at the bottom of the cutting;

[0020] Five, lay geosynthetics ...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that: the excavation depth in step 1 is not less than the standard freezing depth. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the pile distance of the drilling construction described in step 2 is 2-2.5m, and the hole diameter is 0.35-0.45m. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com