Construction Technology of Concrete Dam Body of Waste Landfill

A technology for landfill and construction technology, which is applied in filling, infrastructure engineering, construction, etc., and can solve the problems of large pouring workload, high production cost, and large demand for formwork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

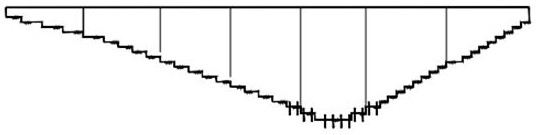

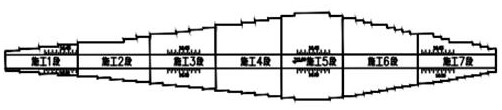

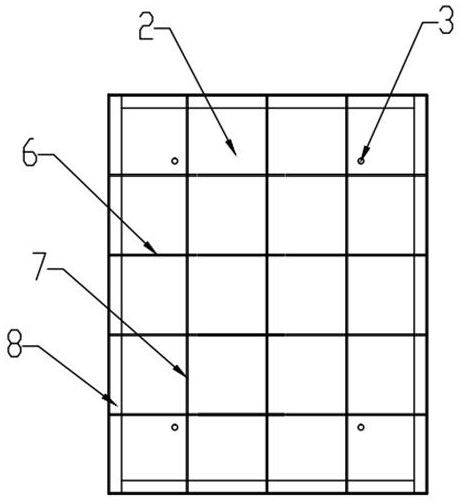

[0026] The construction technology of the concrete dam body of the refuse landfill provided in this embodiment includes the following steps: S1, preliminary preparation, site selection according to the needs of the landfill site and geological field survey of the selected site; S2, according to the investigation situation Use CAD to draw the dam structure diagram of the landfill site, the dam body is deep in the middle, shallow on both sides, and has a stepped cross-section; on the dam body, set a deformation joint every 15-20m; S3, set out the line and excavate the base of the dam body stepwise, and at the same time, prepare the formwork according to the shape and size of the dam body at each level in the dam structure diagram; S4, pour the cushion on the excavated base of the dam body; S5, Divide multiple construction areas on the dam body cushion along the length direction of the dam body and longitudinally along the preset positions of the deformation joints, and install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com