Composite insulation board and manufacturing method thereof

A composite thermal insulation and production method technology, applied in thermal insulation, building components and other directions, can solve the problems of incompatibility, separation of the board body, shedding and separation, etc., to achieve promotion and application promotion, avoid shedding and separation, and the effect of reasonable location.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

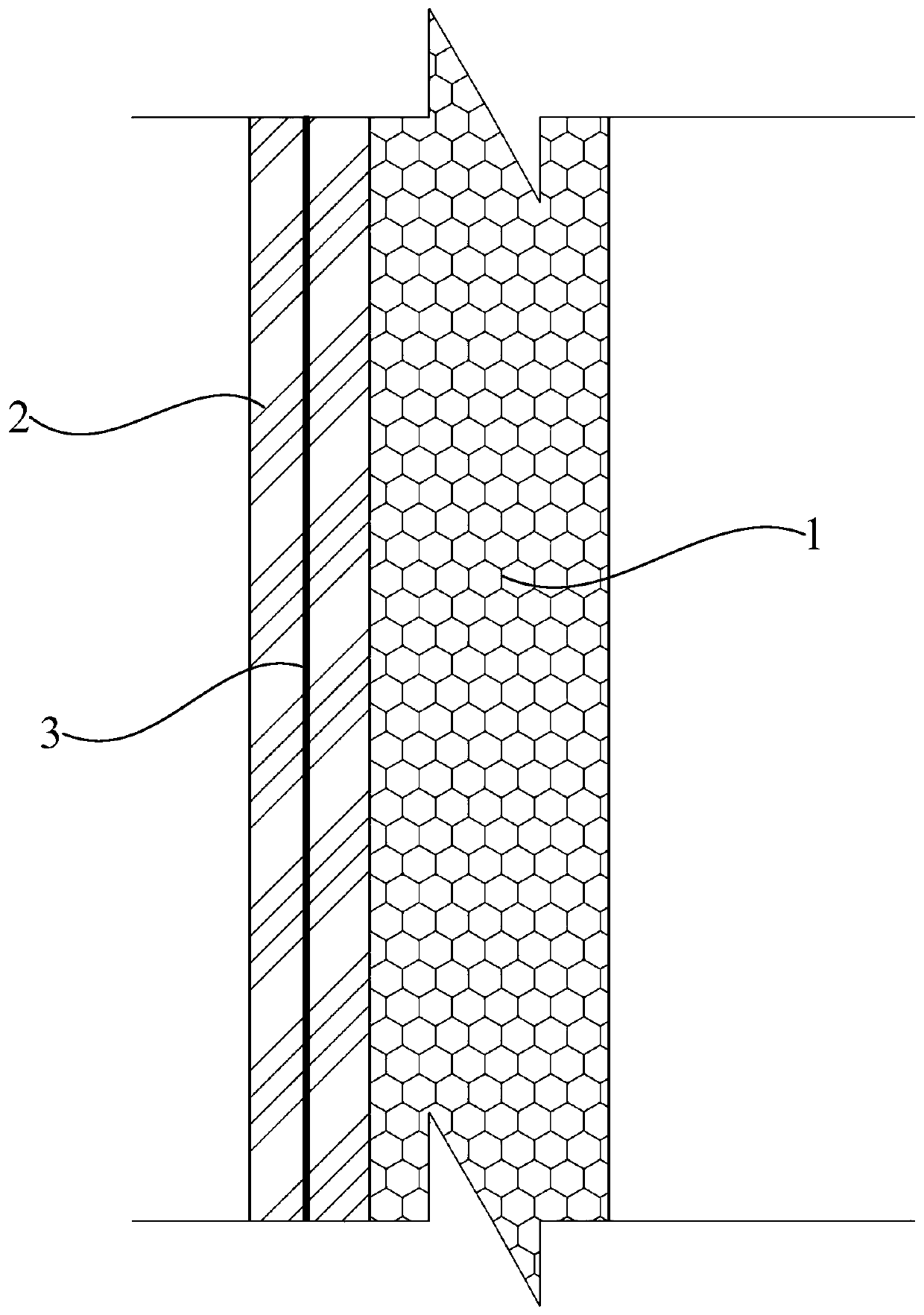

[0035] Such as figure 1 As shown, this embodiment discloses a composite thermal insulation board, which comprises an inorganic thermal insulation layer 2, an organic-inorganic composite thermal insulation layer 1 and at least one reinforcement layer 3, one side of the inorganic thermal insulation layer 2 is connected with the organic-inorganic composite thermal insulation layer 1 phase connection, and the reinforcement layer 3 is connected in the inorganic insulation layer 2.

[0036] Through the compatibility of the inorganic material in the inorganic thermal insulation layer 2 and the organic-inorganic composite thermal insulation layer 1, the structural connection strength of the composite thermal insulation board is strengthened, and the falling and separation of the composite thermal insulation board is effectively avoided. At the same time, the reinforcement layer 3 is arranged inside the inorganic insulation layer 2, and the location of the reinforcement layer 2 is more...

Embodiment 2

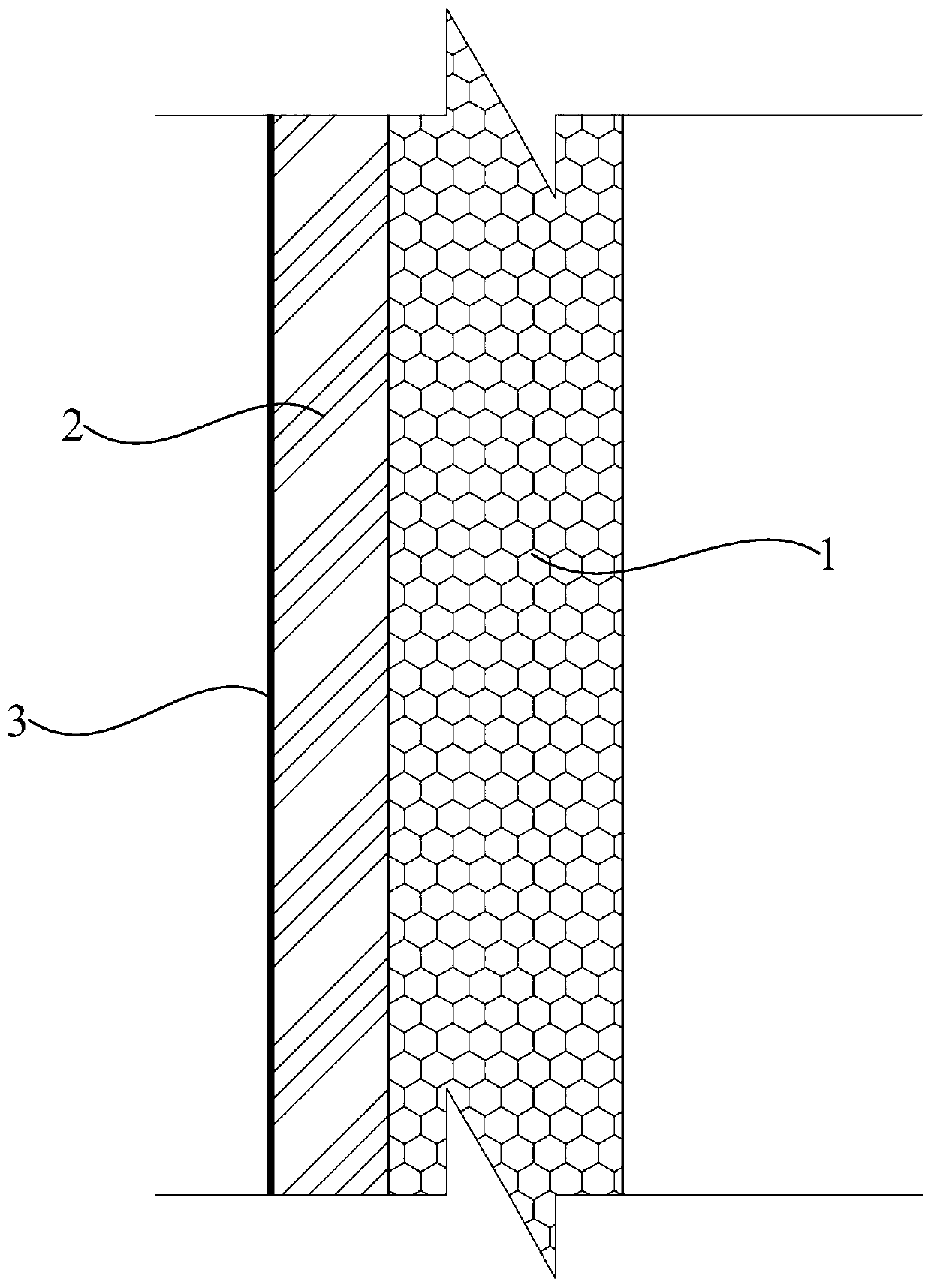

[0069] The parts of the second embodiment that are the same as those of the first embodiment will not be repeated, and only the different parts will be described. Such as figure 2 As shown, in the composite insulation board, one side of the inorganic insulation layer 2 is connected to the organic-inorganic composite insulation layer 1, and the reinforcement layer 3 is connected to the other side of the inorganic insulation layer 2. Both sides of the inorganic thermal insulation layer 2 are respectively connected to the reinforcement layer 3 and the organic-inorganic composite thermal insulation layer 1, so that the position of the reinforcement layer 3 on the composite thermal insulation board meets the preset requirements.

[0070] In the manufacturing method of the composite thermal insulation board, the second step is specifically: laying the reinforcing layer 3 in the mold first, and then laying the raw material composition of the inorganic thermal insulation layer 2 to f...

Embodiment 3

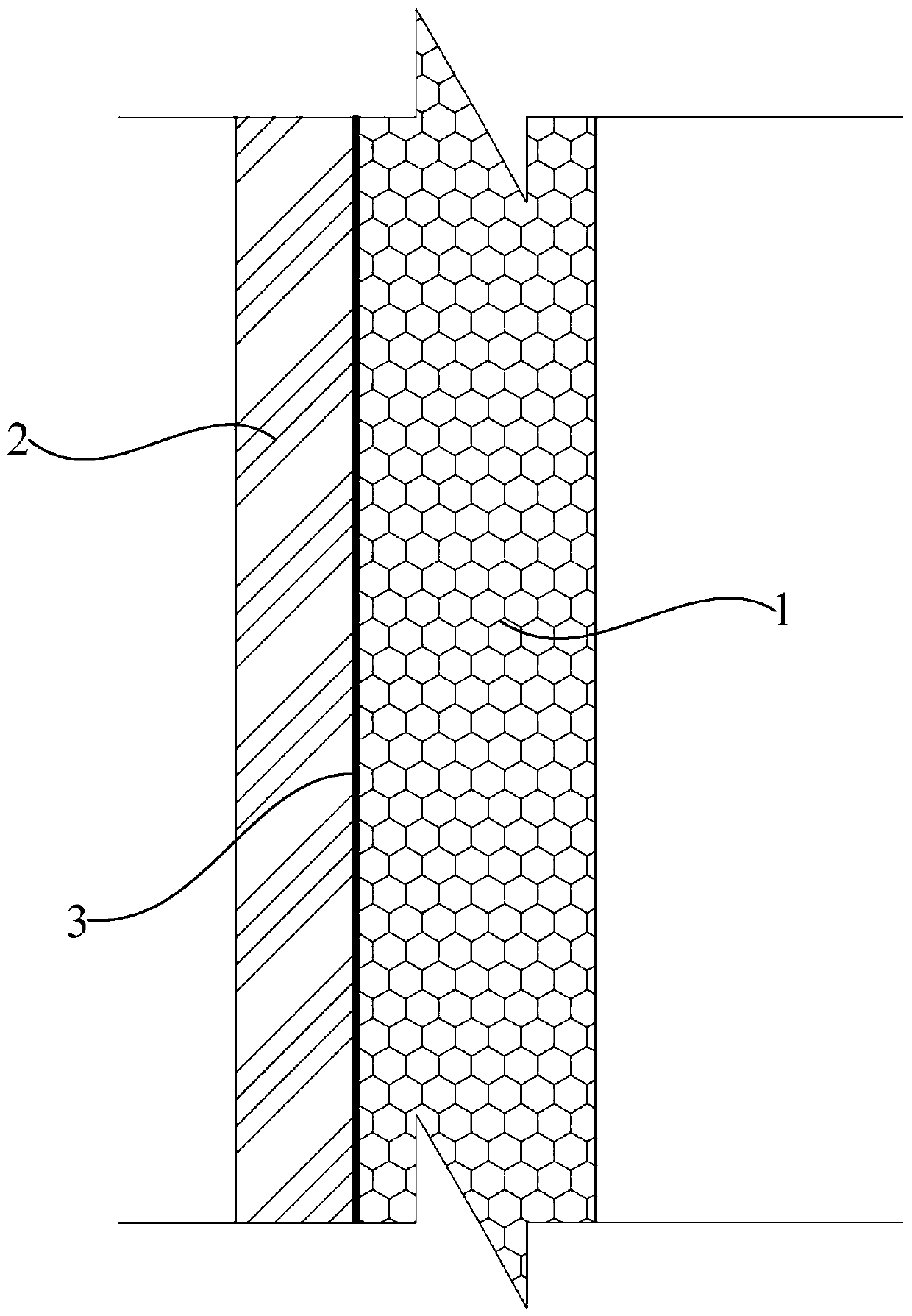

[0072] The parts of this embodiment 3 that are the same as those of the embodiment 1 will not be repeated, and only the different parts will be described. Such as image 3 As shown, in the composite insulation board, one side of the inorganic insulation layer 2 is connected to the organic-inorganic composite insulation layer 1, and the reinforcement layer 3 is arranged between the inorganic insulation layer 2 and the organic-inorganic composite insulation layer 1 and connected to the inorganic insulation layer 2. , The organic-inorganic composite insulation layer 1 is connected. The reinforcement layer 3 is arranged on the inorganic insulation layer 2 and the organic-inorganic composite insulation layer 1, so that the inorganic insulation layer 2, the organic-inorganic composite insulation layer 1 and the reinforcement layer 3 are connected, which strengthens the structural connection strength of the composite insulation board and effectively avoids the composite The insulati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap