Internal suction type hollow shaft rotary chrysanthemum picking machine and picking method thereof

The technology of a hollow shaft and a picking machine is applied in the field of picking devices and picking devices for chrysanthemum picking. good collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

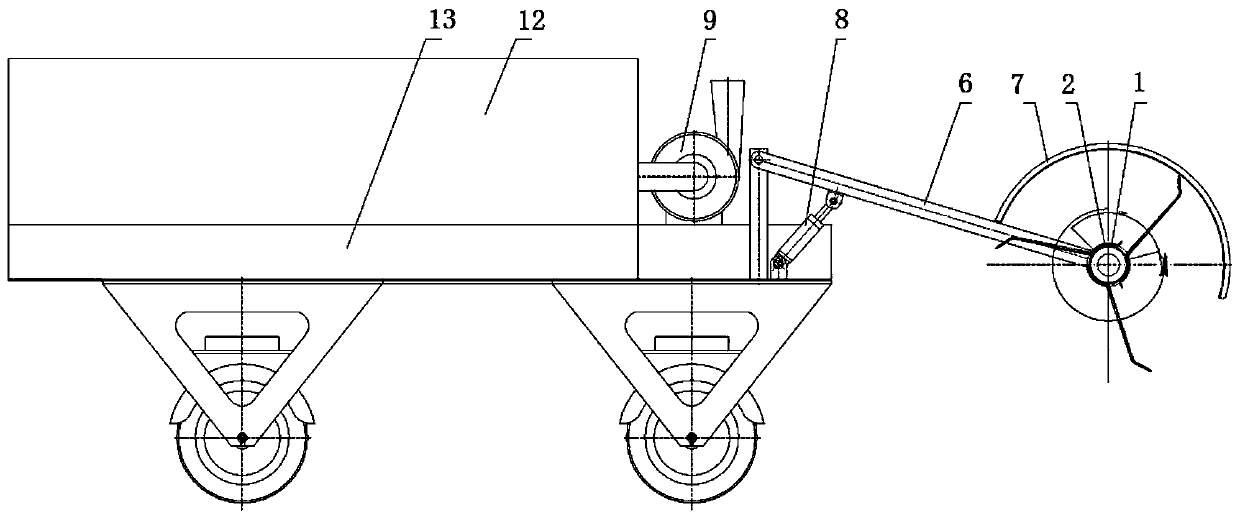

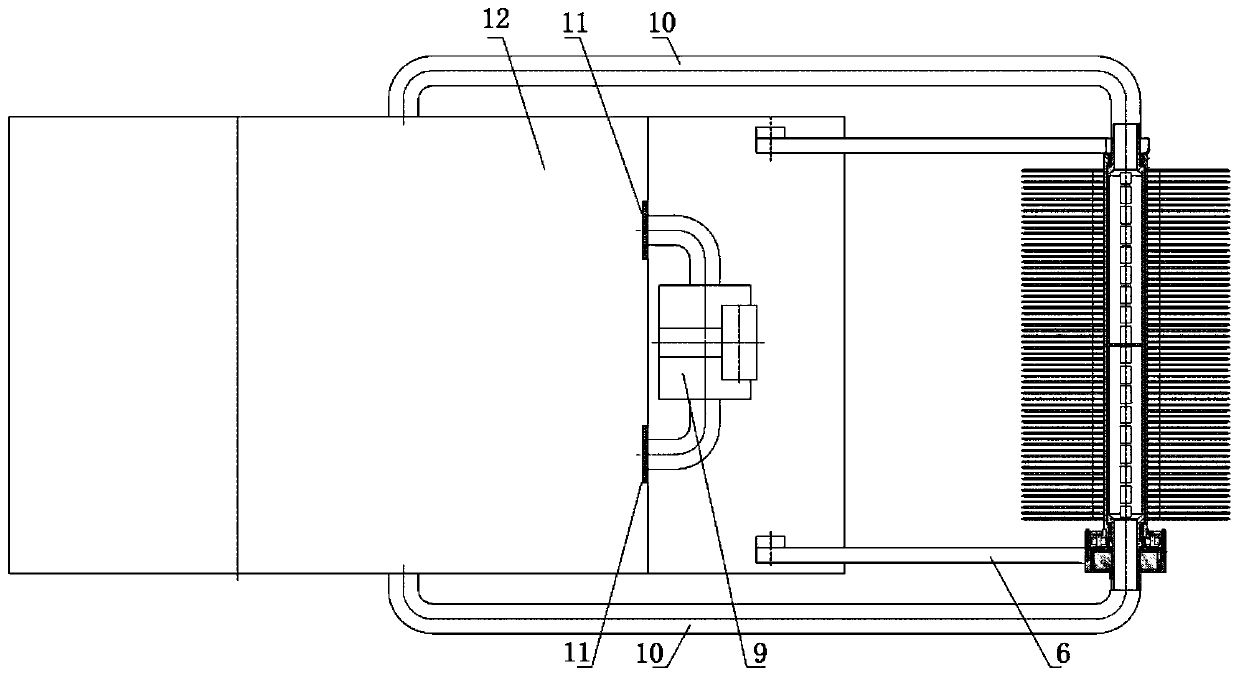

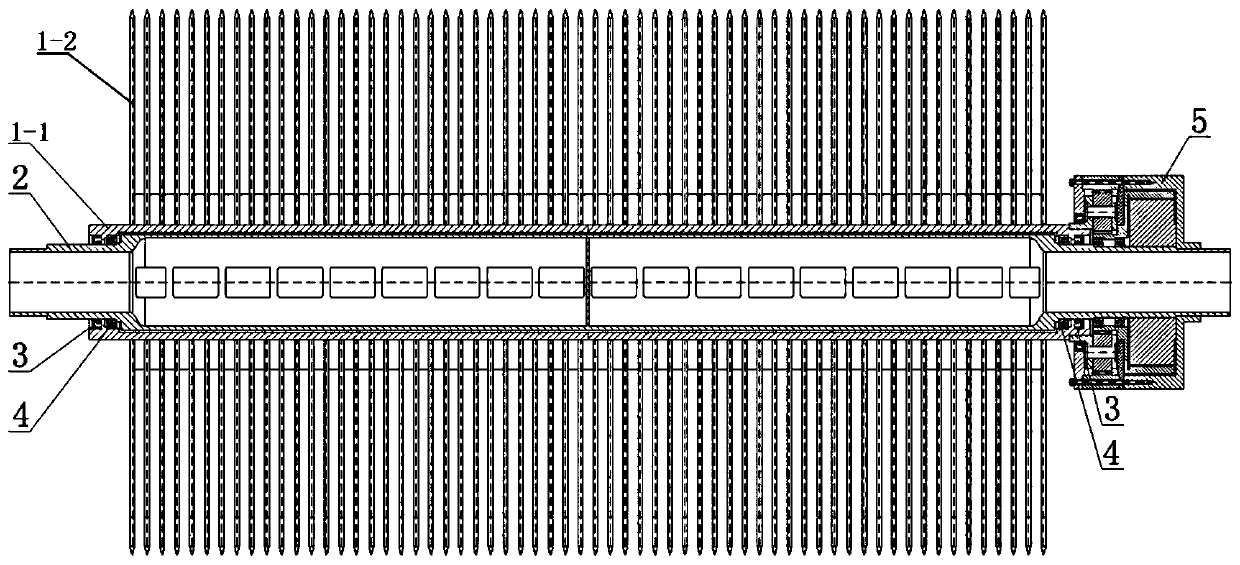

[0035] This embodiment provides a Figure 1-2 The shown internal suction hollow shaft rotary chrysanthemum picker. The internal suction type hollow shaft rotary chrysanthemum picking machine includes a chassis 13, a vacuum pump 9, a picking head, and the picking head includes a hollow shaft 2, a rotary picking mechanism, and a driving mechanism.

[0036] In order to improve the automation level and further reduce manpower input, the chassis 13 in this embodiment is an automatic chassis, which specifically adopts an independent four-wheel drive electric chassis, which has the function of unmanned driving. According to the map of the chrysanthemum field, the working route can be independently planned or manually controlled. model. It is also possible to use manned agricultural chassis according to actual needs.

[0037] An airtight storage box 12 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com