A gear end surface grinding device for gear processing

A gear end and gear technology, applied in the field of gear processing, can solve the problems of low grinding efficiency of the gear end face, inconvenient waste disposal, etc., and achieve the effects of simple structure, improved grinding efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

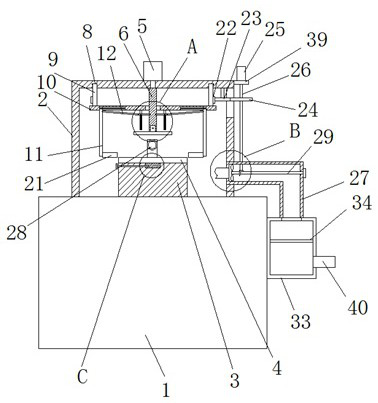

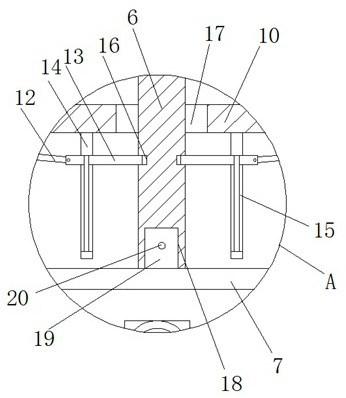

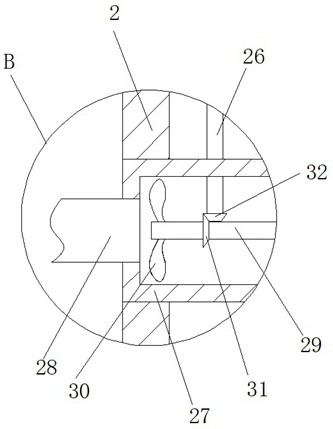

[0029] refer to Figure 1-5 , a gear end surface grinding device for gear processing, comprising a placing seat 1, a placing table 3 is fixedly installed on the top of the placing seat 1, the top of the placing table 3 is provided with a first grinding plate 4, and the top of the first grinding plate 4 is provided with There is a second polishing plate 7, the top of the second polishing plate 7 is provided with a push column 6, the top of the placement seat 1 is fixedly installed with a frame 2, the bottom of the frame 2 is rotatably installed with an annular plate 9, and the bottom of the annular plate 9 is fixedly installed with a The fixing plate 10, the fixing plate 10 is provided with a through hole 17, the bottom of the push column 6 passes through the through hole 17, the bottom of the fixing plate 10 is slidably installed with two push plates 11, and the two push plates 11 are rotated on the side close to each other One end of the push rod 12 is installed, the other en...

Embodiment 2

[0040] refer to Figure 1-5 , a gear end surface grinding device for gear processing, comprising a placing seat 1, the top of the placing seat 1 is fixedly installed with a placing table 3 by bolts, the top of the placing table 3 is provided with a first grinding plate 4, A second polishing plate 7 is arranged above, a push column 6 is arranged on the top of the second polishing plate 7, a frame 2 is fixedly installed on the top of the placing seat 1 by bolts, and an annular plate 9 is installed at the bottom of the frame 2. A fixing plate 10 is fixedly installed at the bottom by bolts, the fixing plate 10 is provided with a through hole 17, the bottom of the push column 6 penetrates the through hole 17, and the bottom of the fixing plate 10 is slidably installed with two push plates 11, and the two push plates 11 are mutually One end of the push rod 12 is rotatably installed on the adjacent side, and the other end of the two push rods 12 is rotatably installed with a lift rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com