Online grinding construction method for railway steel rail mounting groove

A construction method and installation groove technology are applied in the field of online grinding and construction of railway rail installation grooves, which can solve problems such as reducing operation safety risks, and achieve the effects of solving deformation adjustment problems, low disposal costs, and low operation safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

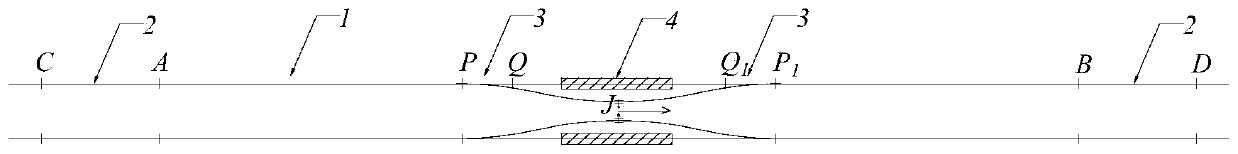

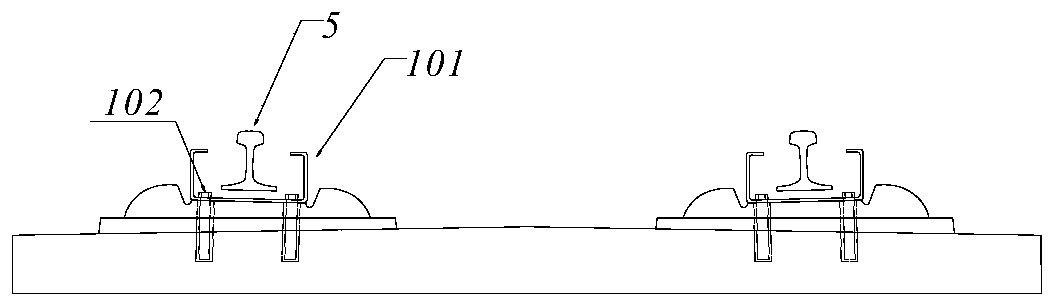

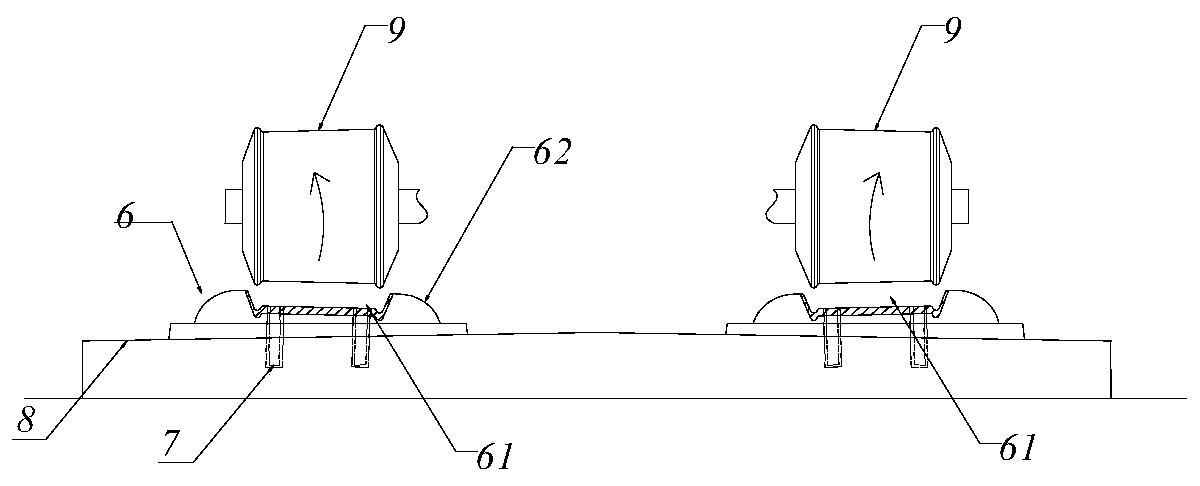

[0025] refer to figure 1 , figure 2 and image 3 , a kind of railway rail mounting groove online grinding construction method of the present invention, comprises the following steps:

[0026] 1) According to the condition and location of the disease, determine the length of the line adjustment section 1, that is, determine the position of the starting point A of the milling operation and the position of the end point B of the milling operation, measure the line adjustment section 1 pillow by pillow, and obtain the vertical and vertical dimensions of each pillow position. Transverse milling amount;

[0027] 2) To measure the rail temperature, the construction rail temperature should not be greater than the design locked rail temperature. If the construction rail temperature is greater than the design locked rail temperature, it is necessary to increase the technical measures for auxiliary cooling;

[0028] 3) The rail installation groove milling and grinding vehicle arrives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com