Mounting base for GIS equipment

A technology for installing foundations and equipment, which is applied in the direction of basic structure engineering, buildings, building components, etc., can solve problems such as hindering the laying of steel bars, cables, etc. , Strong engineering adaptability, and the effect of reducing the erection period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

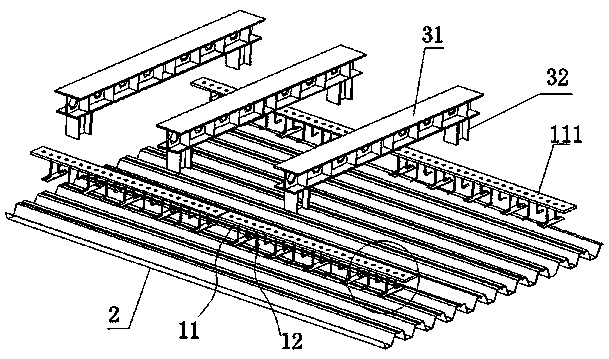

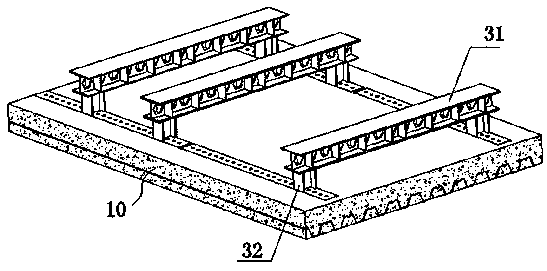

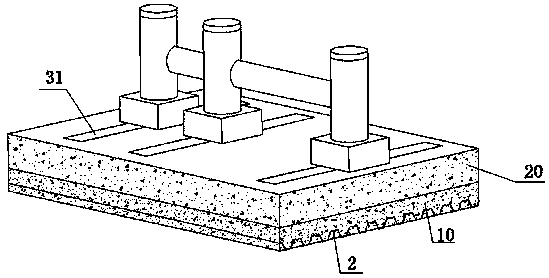

[0025] Such as Figure 1 to Figure 5 , the installation foundation of a kind of GIS equipment of the present invention, comprises strip plate 11, anchoring steel bar 12, support plate 13, steel beam 31, rigid pier 32, embedded part layer 10, soil surface layer 20 and have the pressure of front surface and valley surface Type steel plate 2.

[0026] Several anchoring reinforcement bars 12 are welded on the strip plate 11 in parallel and at a certain interval, and the bottom surface of at least two anchoring reinforcement bars 12 on each strip plate 11 is welded with a support plate 13, and the two strip plates 11 pass through correspondingly. The support plates 13 are placed parallel to each other on the front surface of the profiled steel plate 2, the strip plate 11, the anchoring steel bar 12, the support plate 13 and the profiled steel plate 2 are pre-embedded in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com