Preforming and Erecting Construction Method of Main Cable Strands of Suspension Bridge

A construction method and pre-forming technology, applied in suspension bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unfavorable long-term durability of cable strands, difficulty in ensuring safety and quality, and damage to steel wire galvanized layers. The effect of shortening the erection period, guaranteed molding quality, and professional equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

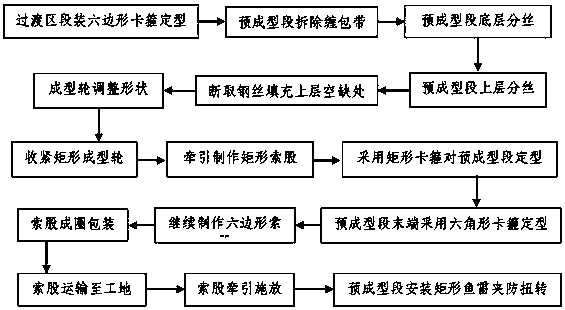

Method used

Image

Examples

specific Embodiment

[0064] Yunnan Longjiang Super Bridge is the first large bridge project in China to apply the pre-forming technology of main cable strands. The strands of the main cable unit are shaped into a quadrilateral shape in advance.

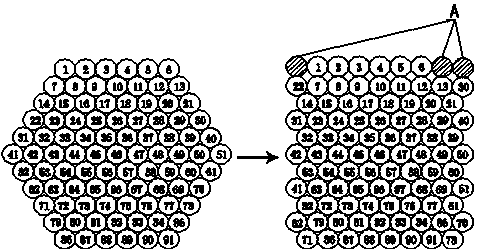

[0065] The Longjiang Super Bridge in Yunnan Province is a key control project of the Baoshan-Myanmar Highway in Yunnan and the Baoshan-Tengchong section of the highway. The bridge adopts a double-tower single-span steel box with a main span of 1196 meters (320+1196+320 meters). The beam suspension bridge ranks first among the suspension bridges across the canyon in the world. All the main cables and suspenders of the Longjiang Super Bridge are manufactured by Pujiang Cable Co., Ltd. There are 2 main cables and 338 cables in total. The unit cable adopts prefabricated parallel steel wire strands (PPWS), each strand is composed of 91 galvanized high-strength steel wires with a diameter of 5.25mm, and the standard tensile strength is 1770MPa. A single main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com