Anchor Support Technology of Front Guide Beam of 900 Type Bridge Erecting Machine for Railway Passenger Dedicated Line

A technology of anchor frame and bridge erecting machine, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc. It can solve the problems of increasing the difficulty of pier construction, increasing material input, and affecting the erection of box girders, so as to shorten the period of girder erection, The effect of shortening the erection cycle and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

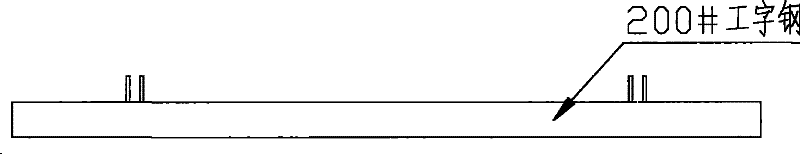

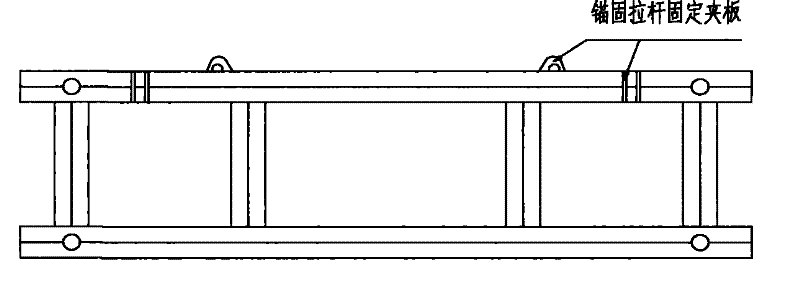

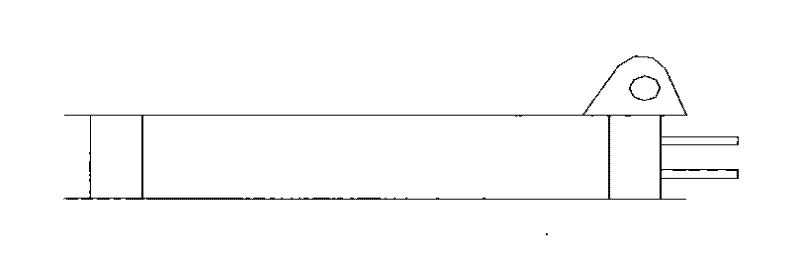

[0016] The anchor bracket of the front guide beam of the bridge erecting machine is processed into a box-shaped steel girder as a whole by butt welding of 200mm I-beam, on which 8 pieces of anchor rods processed by 20mm thick steel plate are welded to fix the splint. It is the anchor screw rod used to connect the anchor bracket with the prefabricated concrete simply supported box girder of the passenger dedicated line. The bolts lock the anchor bracket and the precast concrete simply supported box girder of the passenger dedicated line together. At the same time, weld the screw fixing splint on the rear end of the leading beam of the bridge erecting machine, and make it correspond to the position of the fixing splint on the anchor bracket. During implementation, the fixed splint on the leading beam of the bridge erecting machine is connected with the anchor bracket by using a two-way telescopic lead screw available on the market.

[0017] The technical invention has been veri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com