Hydraulic lifting building scaffold

A hydraulic lifting and scaffolding technology, which is applied to scaffolding supported by house structures, buildings, building structures, etc., can solve the problems of large one-time investment, large material consumption, low safety performance, etc., and achieve labor intensity reduction, simple operation, The effect of excellent structural strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

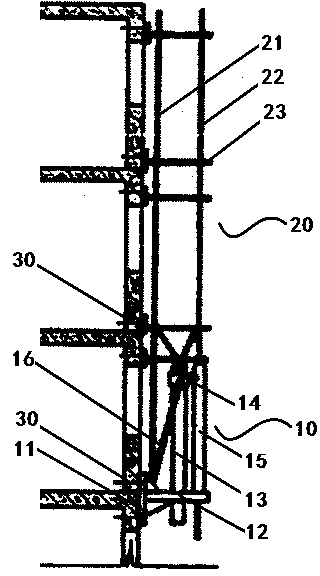

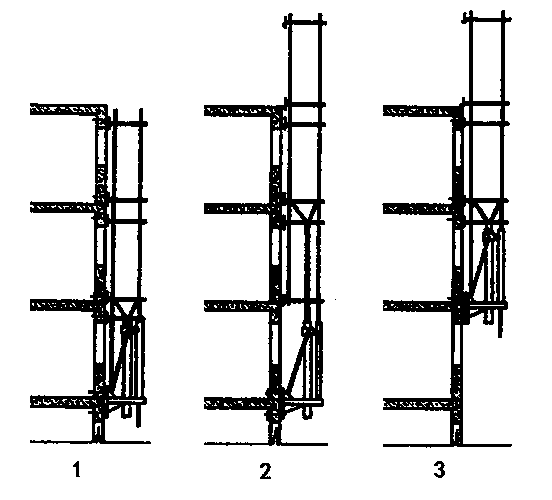

Embodiment 1

[0018] as attached figure 1 As shown, the hydraulic lifting type construction scaffold described in this embodiment is composed of a hydraulic lifting mechanism 10 and a scaffolding structure 20, and the hydraulic lifting mechanism 10 and the scaffolding structure 20 are fixed to the wall by locking bolts 30; Described scaffolding structure 20 mainly is made of inner tripod bar 21, outer tripod bar 22 and a plurality of cantilever beams 23; Described cantilever beam 23 is fixed on described inner tripod bar 21 and outer tripod bar 22 and extends to the wall body, and fixed to the wall by locking bolts 30; the hydraulic lifting mechanism 10 includes a support base plate 11, a support beam 12 and a hydraulic cylinder 13 with a telescopic rod; the support beam 12 is welded on the support base plate 11 above, and the hydraulic cylinder 13 is arranged in the middle of the support beam 12; the outer end of the support beam 12 is provided with a guide column 15, and the upper end of ...

Embodiment 2

[0020] In this embodiment, the scaffold structure material is made of low-carbon steel, because low-carbon steel can provide good welding performance; however, in order to further improve the safety factor of the scaffold structure, especially the safety under low temperature conditions coefficient, it is also necessary to improve the toughness or low-temperature weldability of the low-carbon steel, for which the following solutions are provided in this embodiment:

[0021] In order to ensure economical efficiency, the low-carbon steel described in this example adopts the design idea of low-carbon and low-silicon, and prepares a low-carbon steel with excellent comprehensive properties; it not only ensures the mechanical properties required by the steel, but also has excellent Excellent low temperature toughness and welding performance. For this reason, the low-carbon steel described in this embodiment is to heat the following steel materials to 1000~1080°C, and finish hot ro...

Embodiment 3

[0031]In this embodiment, in order to avoid frequent inspection and replacement of the locking bolt, the locking bolt is made of a hard steel base and a hardened coating. Wherein, the hard steel matrix contains: C: 0.20~0.25%, Si: 0.05~0.15%, Mn: 1.25~1.50%, Ni: 0.42~0.70%, Cr: 1.08~1.25%, Cu: 0.03~ 0.08%, Al: 0.05~0.08%, Mg: 0.005~0.010%, B: 0.001~0.005%, N≤0.01%, P≤0.025%, S≤0.01%, and the balance is Fe and unavoidable impurities. The hard steel is cast according to a conventional method, and then hot-processed to form a hard steel matrix; then, plasma nitriding is performed on the hard steel matrix, and the nitriding temperature is 520-540°C and the surface layer of the hard steel matrix is Form a nitrided layer with a thickness of 100-150 microns in the nitrided layer, and the concentration of nitrogen in the nitrided layer is 7.5-8.0wt%; then spray a composite coating (such as thermal spraying or cold spraying) on the surface of the nitrided layer, heat To 500~520°C, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com