Field testing equipment and method for heat transfer coefficient of building envelope

A building envelope structure and heat transfer coefficient technology, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problems of heat transfer coefficient deviation, difficult installation, long test time, etc., to achieve simple equipment structure and small calculation error , The effect of small programming difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

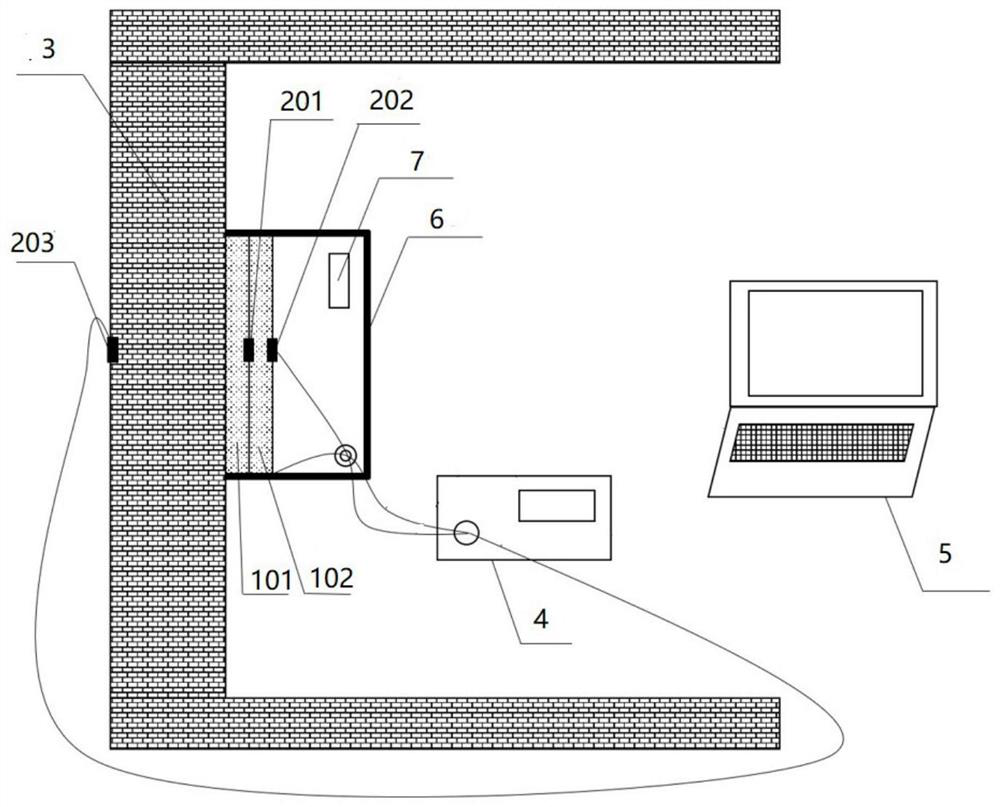

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 The on-site test equipment for the heat transfer coefficient of the building envelope shown, including the main part of the equipment and the data acquisition and processing part;

[0024] The main part of the device includes: a first auxiliary test material plate 101, a second auxiliary test material plate 102, a first temperature sensor 201, a second temperature sensor 202 and a third temperature sensor 203, the first auxiliary test material plate 101 Close to the inner surface of the enclosure structure 3 to be tested, the second auxiliary test material plate 102 is close to the outer surface of the first auxiliary test material plate 101, and the first temperature sensor 201 is arranged on the first auxiliary test material plate 101. The joint between the plate 101 and the second auxiliary test mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com