Motor assembling and fixing structure, voice coil motor, photographic device and electronic product

A fixed structure and motor technology, applied in the fields of motor assembly and fixed structure, photographic devices, electronic products, and voice coil motors, can solve the problems affecting the performance of the voice coil motor, the small space for hot riveting of the upper spring 3, and the small structure of the voice coil motor, etc. problems, to achieve the effect of improving product quality and yield, avoiding operational difficulties and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

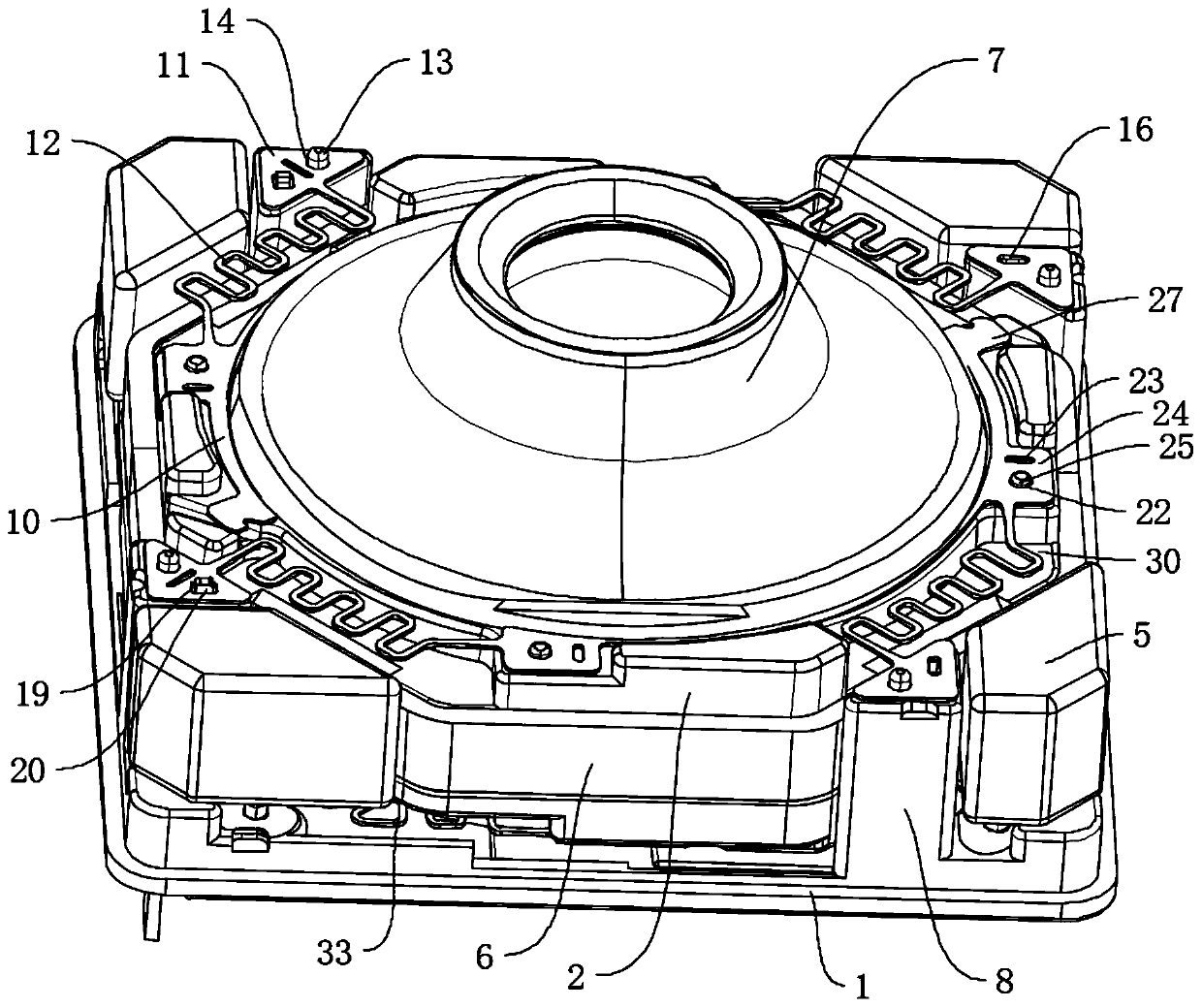

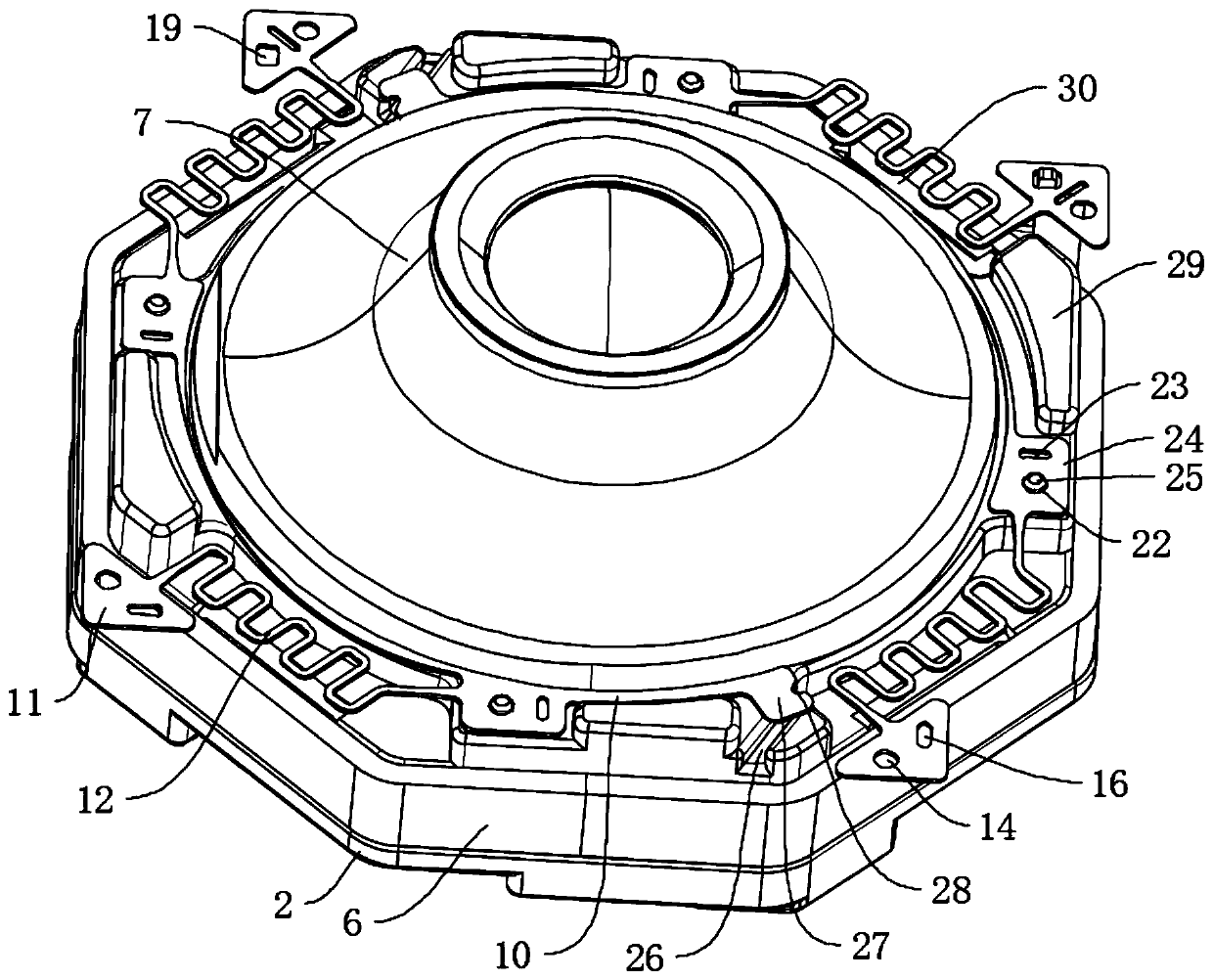

[0032] Embodiment 1: as Figures 1 to 7 As shown, a motor assembly and fixing structure proposed by the present invention includes a base 1, a carrier 2, an upper spring 3, a lower spring 4, a magnet 5, and a coil 6. In this embodiment, the carrier 2 is integrally formed with a lens 7, and through The lens 7 and the carrier 2 are integrally formed to reduce the number of components. The lower spring 4 is installed between the lower end surface of the carrier 2 and the base 1. The base 1 is integrally formed with four evenly distributed positioning columns 8. The magnet 5 is set to four and is located at the corner of the base 1 and attached to the positioning columns 8. The side wall, and the upper spring 3 is arranged between the upper end surface of the positioning post 8 and the upper end surface of the carrier 2 . In addition, four assembling grooves 9 are opened on the lower end surface of the base 1 , and the four assembling grooves 9 respectively extend to the inner ca...

Embodiment 2

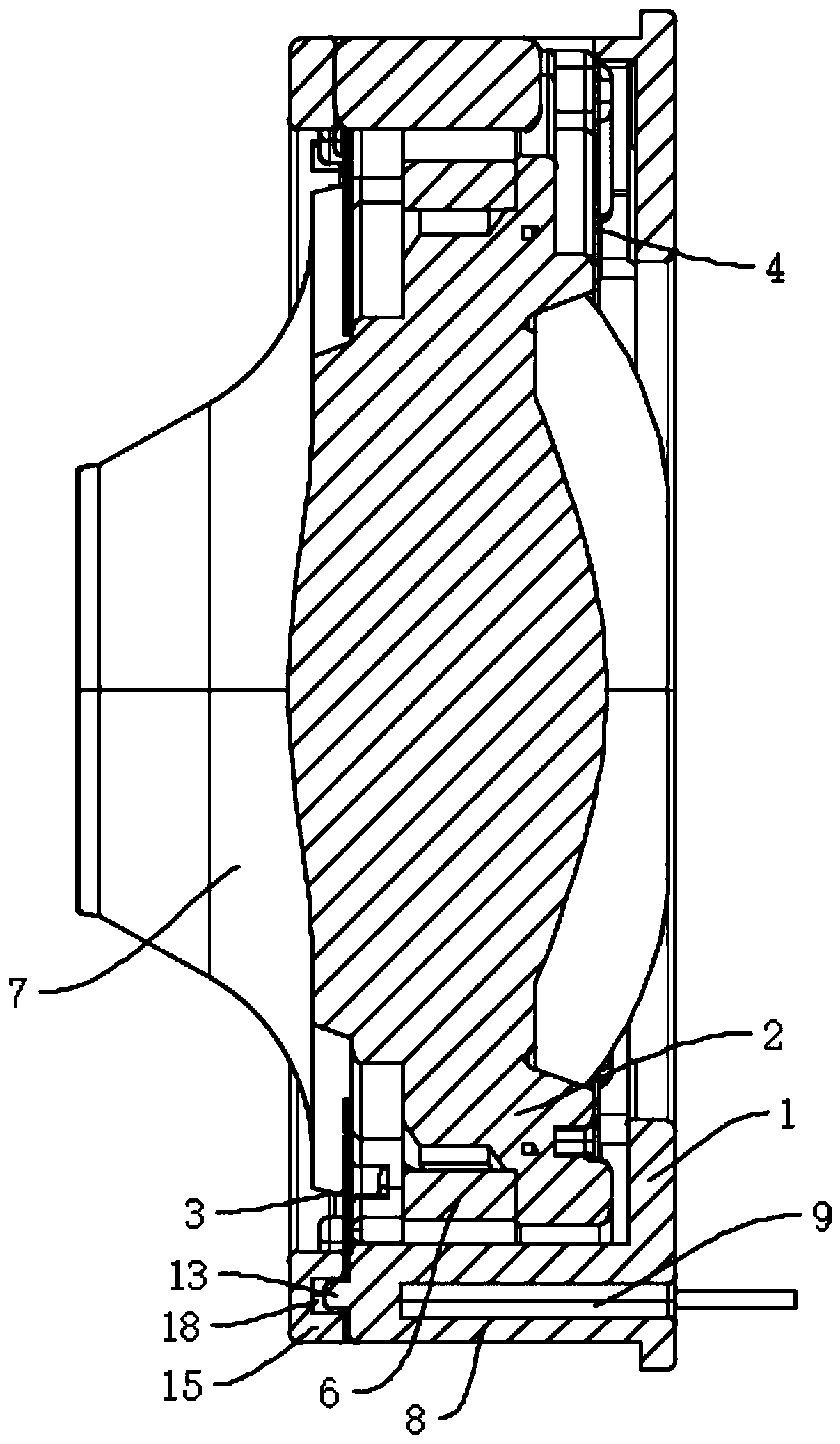

[0041] Embodiment 2: a voice coil motor, such as Figure 8 As shown, the motor assembly and fixing structure of Embodiment 1 also includes a housing 36, the end of the housing 36 is in contact with the base 1, and the cover plate 15 is in contact with the bottom surface of the housing 36, and the side wall of the cover plate 15 is attached to the inner side of the housing 36. The wall abuts against the cover plate 15 through the bottom surface of the shell 36, which can ensure that the cover plate 15 and the positioning column 8 clamp the outer connection portion 11, and effectively restrict the relative movement of the cover plate 15 and the outer connection portion 11.

Embodiment 3

[0042] Embodiment 3: A photographic device having the motor assembly and fixing structure of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com