Roll profile with less unevenness of steel pipe internal threads rolled by Assel unit

A roll shape and internal thread technology, applied in the field of roll shape, can solve problems such as affecting users' use and affecting the appearance of steel pipes, and achieve the effect of optimizing shoulder height, improving market competitiveness, and slowly reducing the wall thickness of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

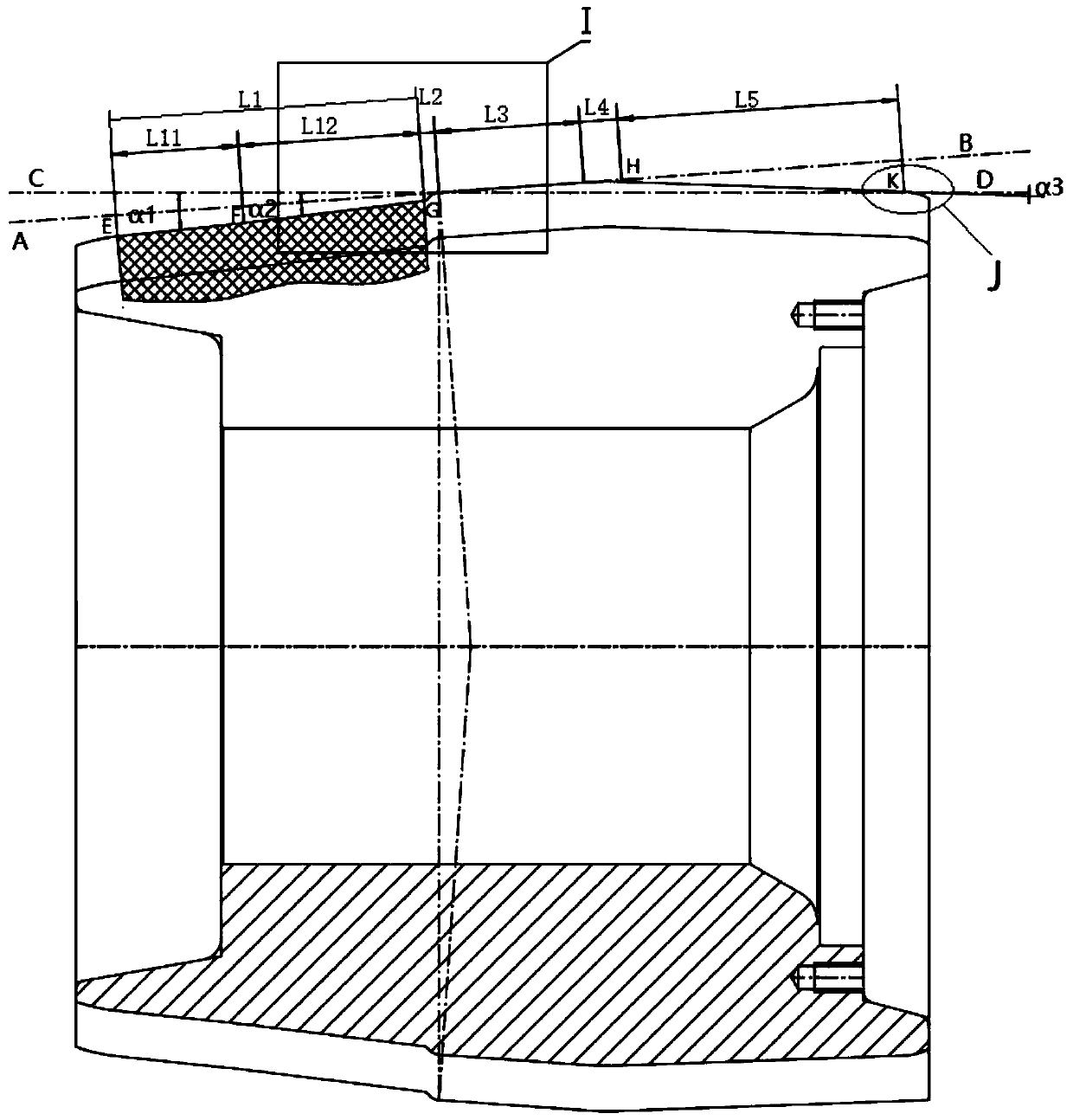

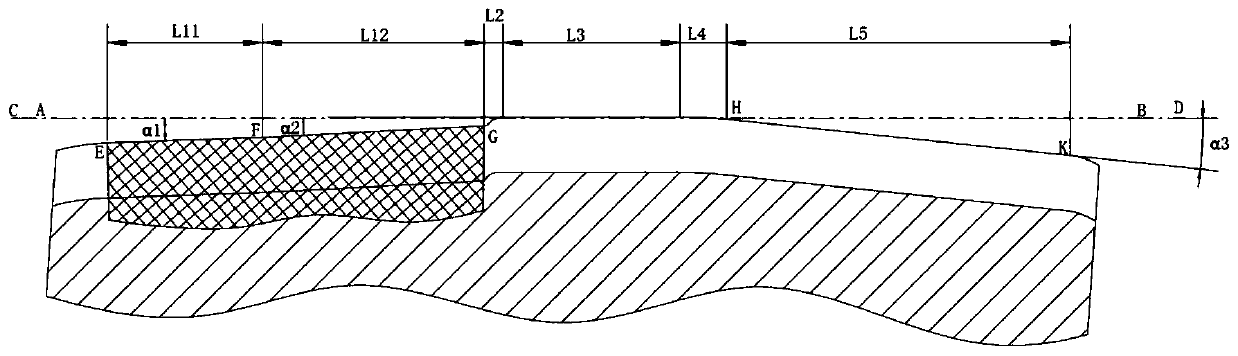

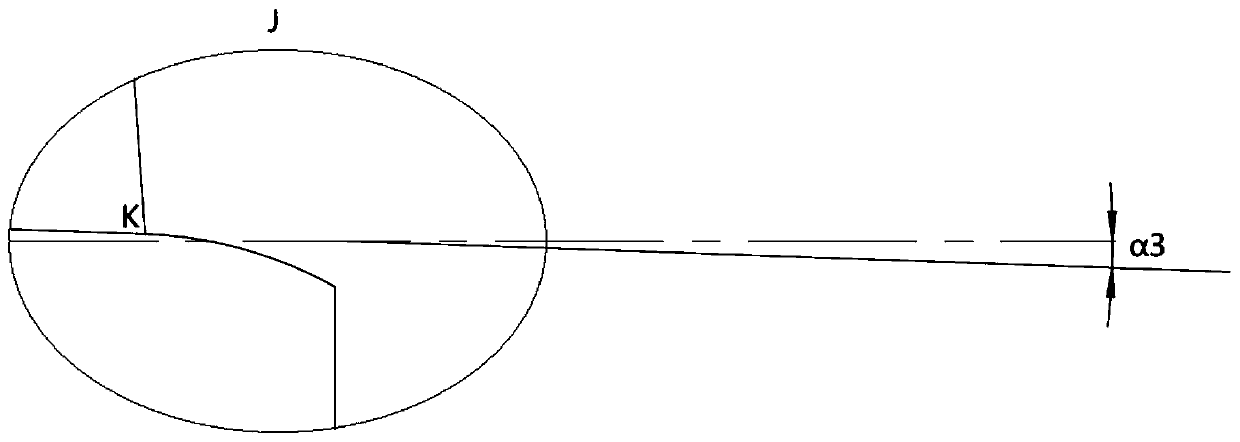

[0035] see figure 1 , image 3 , Figure 4 , Figure 6 , Figure 7 , the invention provides a kind of roll type that alleviates the internal thread of rolling steel pipe of Assel unit, the length of roll is 470mm, and its outer diameter is 500mm, the diameter of its axle hole is 240mm, and the chemical composition (wt%) of its composition has C: 1.65~1.95, Si: 0.4~0.7, Mn: 0.95~1.05, P, S≤0.03, Cr: 1.3~1.8, Ni: 0.8~1.2, Mo: 0.4~0.6, Nb: trace amount, the rest are Fe and unavoidable impurities. From the entrance side to the exit side of the roll, there are successively an entrance cone area L1, a shoulder area L2, a rolling area L3, an exit fillet area L4, and an exit cone area L5, wherein the entrance cone area L1 consists of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com