Transfer trolley with fork and working method of transfer trolley

A working method and technology for transfer vehicles, applied in the direction of lifting devices, etc., can solve the problems of affecting the structural performance, destroying the original structure of the truck, and being difficult to operate, so as to ensure the structural performance, avoid the loss of space, and avoid the effect of transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

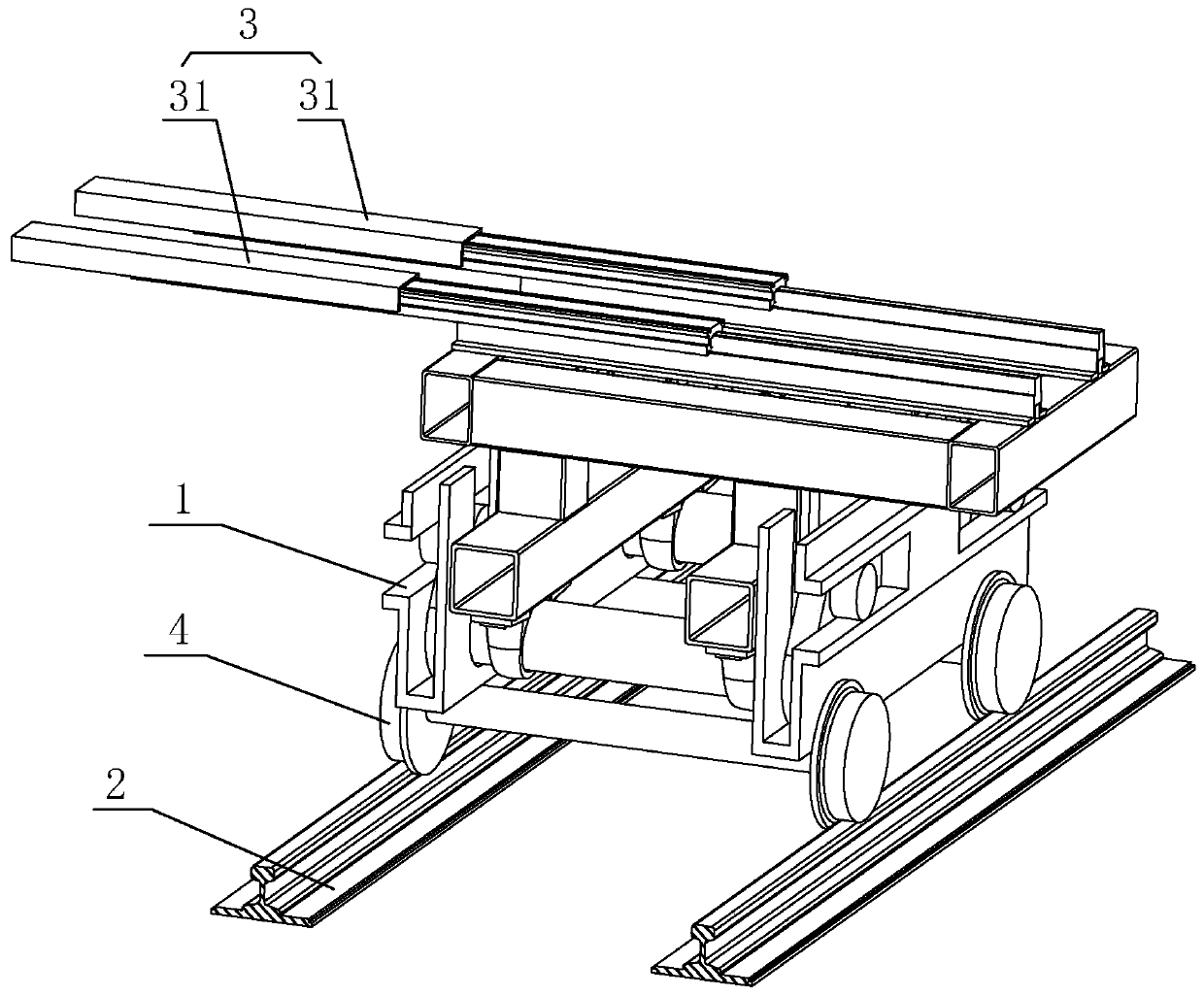

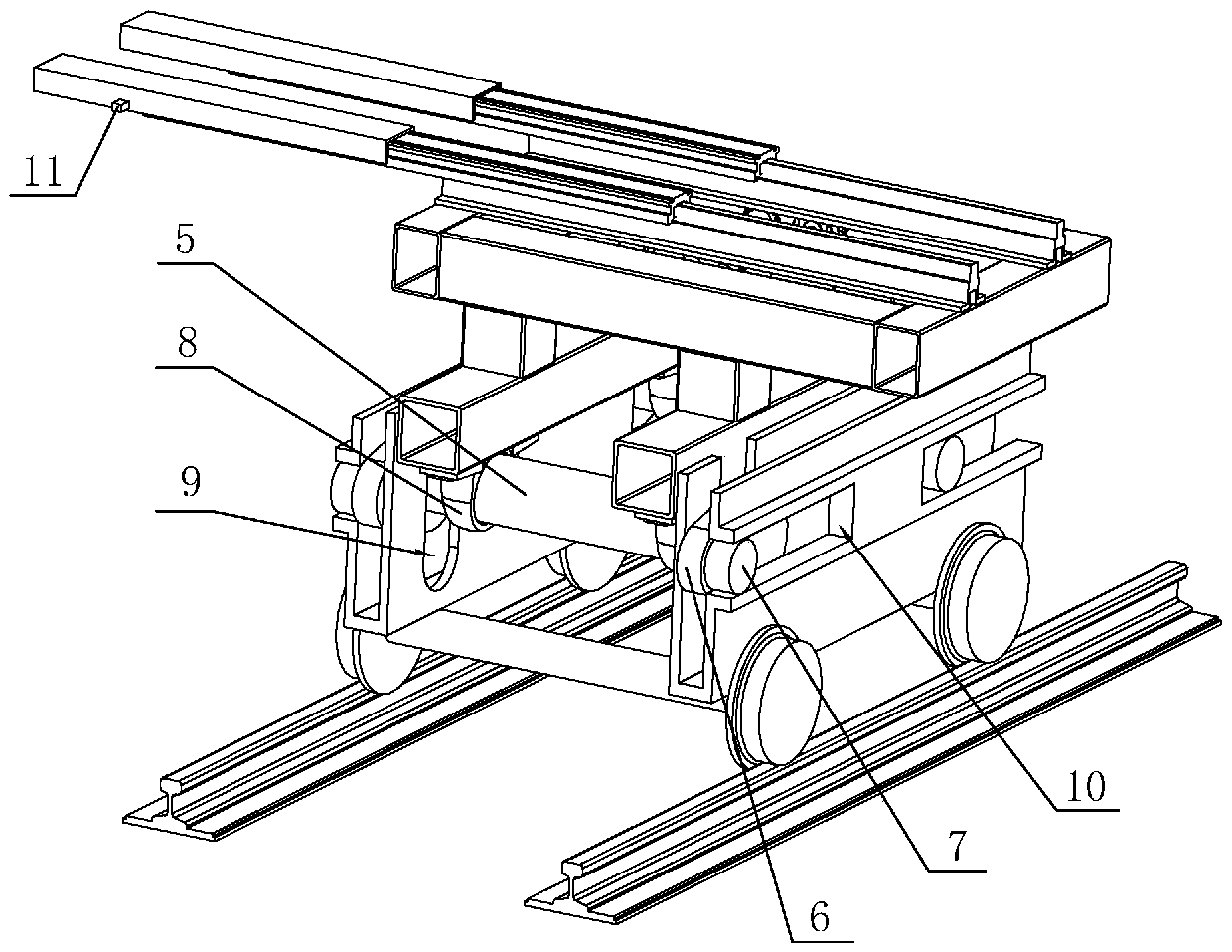

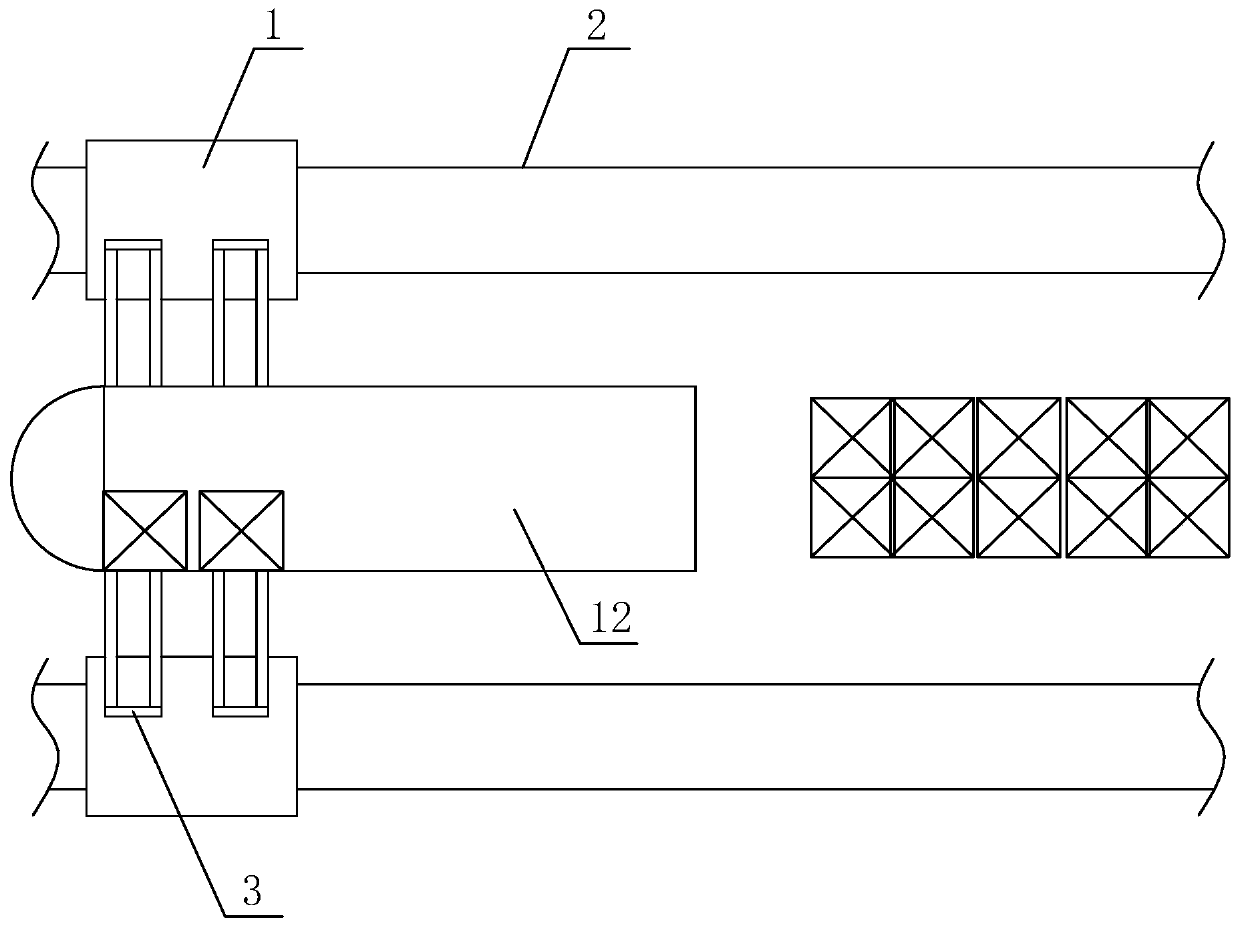

[0027] like figure 1 As shown, a transfer vehicle with a fork includes a car body 1, a guide rail 2, a running device, a height raising device and a telescopic fork 3, two guide rails 2 are arranged in parallel, and the car body 1 is slidably installed on the guide rail 2 Above, the four corners of the car body 1 are equipped with traveling devices, which drive the car body 1 to slide back and forth on the guide slideway, and the telescopic fork 3 is installed on the car body 1, and the telescopic direction of the telescopic fork 3 is the same as that of the car body 1. The running direction of the car body is set vertically, so that the telescopic fork 3 can extend into the top of the bottom of the truck 12 in the horizontal direction. The height difference between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com