A Construction Technology of Prestressed Underpinning for Static Cutting and Pulling Columns

A construction technology and prestressing technology, applied in construction, building maintenance, building construction, etc., can solve problems such as high construction cost, slow construction progress, and low construction safety, so as to ensure construction safety and speed up the progress of the engineering department , Reasonable and orderly construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A prestressed underpinning static cutting and pulling column construction process, the prestressed underpinning static cutting and pulling column includes a reinforced concrete bonded prestressed underpinning structure, a diamond wire saw cutting system and a structural displacement and strain monitoring system, specifically The construction process steps are as follows:

[0043] Step 1. Construct a reinforced concrete bonded prestressed underpinning structure, which specifically includes the following steps:

[0044] (1) Installation and binding of new steel bars: Position and install steel bars according to the construction drawings to ensure the continuous flow of the bottom stressed steel bars in the pile area to be pulled out, and pass through the columns to be pulled out and the whole bar in the opening to avoid the distribution of connection points here In the area, the connection between the new steel bar and the original structure shall be connected by the anch...

Embodiment 2

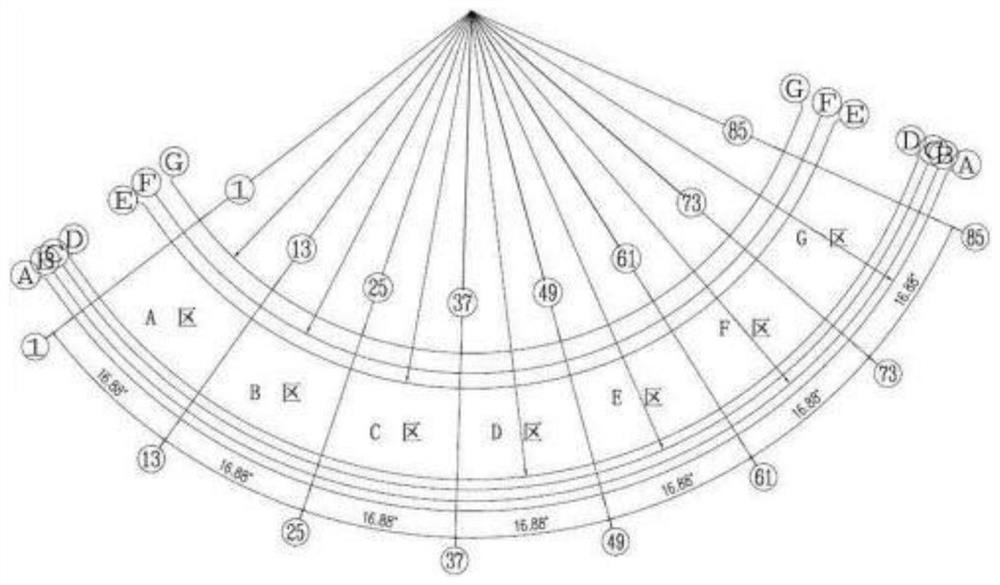

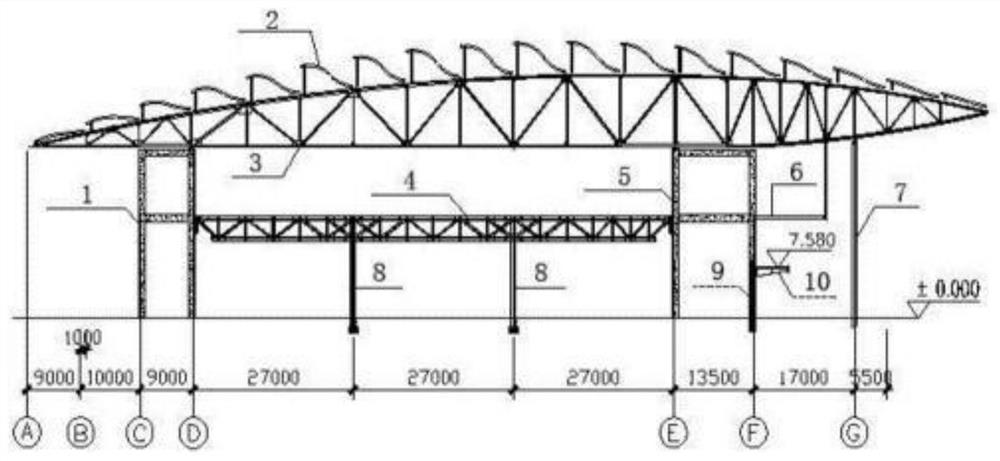

[0065] Such as Figure 1-Figure 13 As shown, taking a fan-shaped structure as an example, it is divided into A, B, C, D, E, F, G axes and A, B, C, D, E, F, G areas, and the distance between the A axis and the center of the circle is 444.200 m, the distance between the B wheel and the center of the circle is 435.200m, the distance between the C wheel and the center of the circle is 425.200m, the distance between the D wheel and the center of the circle is 416.200m, the distance between the E wheel and the center of the circle is 335.200m, the distance between the F wheel and the center of the circle is 321.700m, and the distance between the G wheel and the center of the circle is 304.700m; Line 1 to line 85 has an arc of 118.18 degrees, and is divided into 7 areas. Line 1 to line 13 is area A, line 13 to line 25 is area B, line 25 to line 37 is area C, line 37 to line 49 is area D Line 49 to Line 61 is Zone E, Line 61 to Line 73 is Zone F, Line 73 to Line 85 is Zone G, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com