Rapid positioning detection method and device for automobile headlamp

A positioning detection device and the technology of automobile headlights, which are applied in the field of positioning detection of automobile headlights, can solve the problems of positioning failure, limited light receiving area, and headlight position deviation, etc., and achieve the effect of fast positioning and reduced moving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

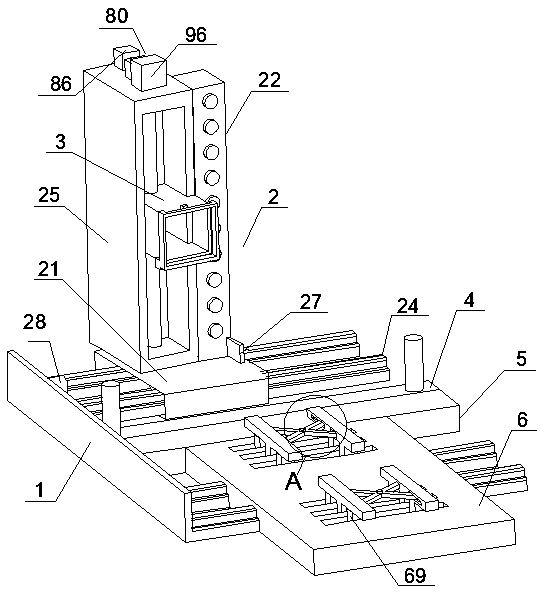

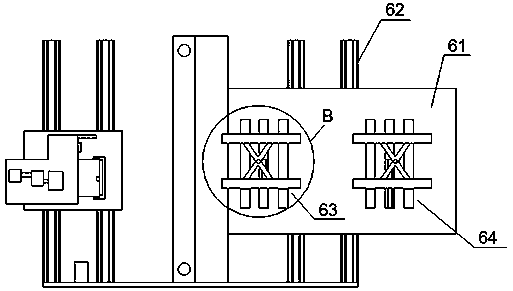

[0047] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

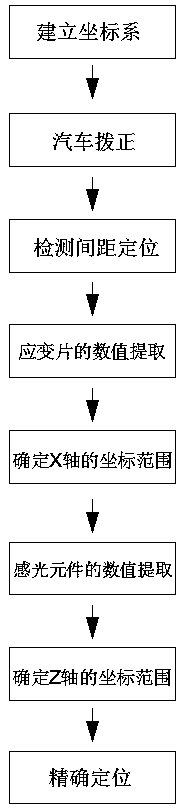

[0048] Such as Figure 1 to Figure 12 Shown, a kind of rapid location detection method of automobile headlamp, comprises the following steps:

[0049] S1, set the coordinate system, the positioning plate 1 is set as the zero point position of the coordinate system, the X-axis guide rail 24 is set as the X-axis, and the Z-axis pillar 25 is set as the Z-axis;

[0050] S2, adjust the orientation of the automobile straightening assembly 6 according to the orientation of the automobile, so that the automobile is driven into the automobile straightening assembly 6, and the automobile is adjusted by the automobile straightening assembly 6;

[0051] S3. After the car is straightened, drive the car to the sensing component 4. When the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com