Waterproof sound box and sound box waterproof process

A sound and submersion technology, applied in the direction of sealed casing, transducer casing/cabinet/bracket, etc., can solve the problems of material waste, poor waterproof performance, etc., and achieve the effect of reducing waste, stable structure and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

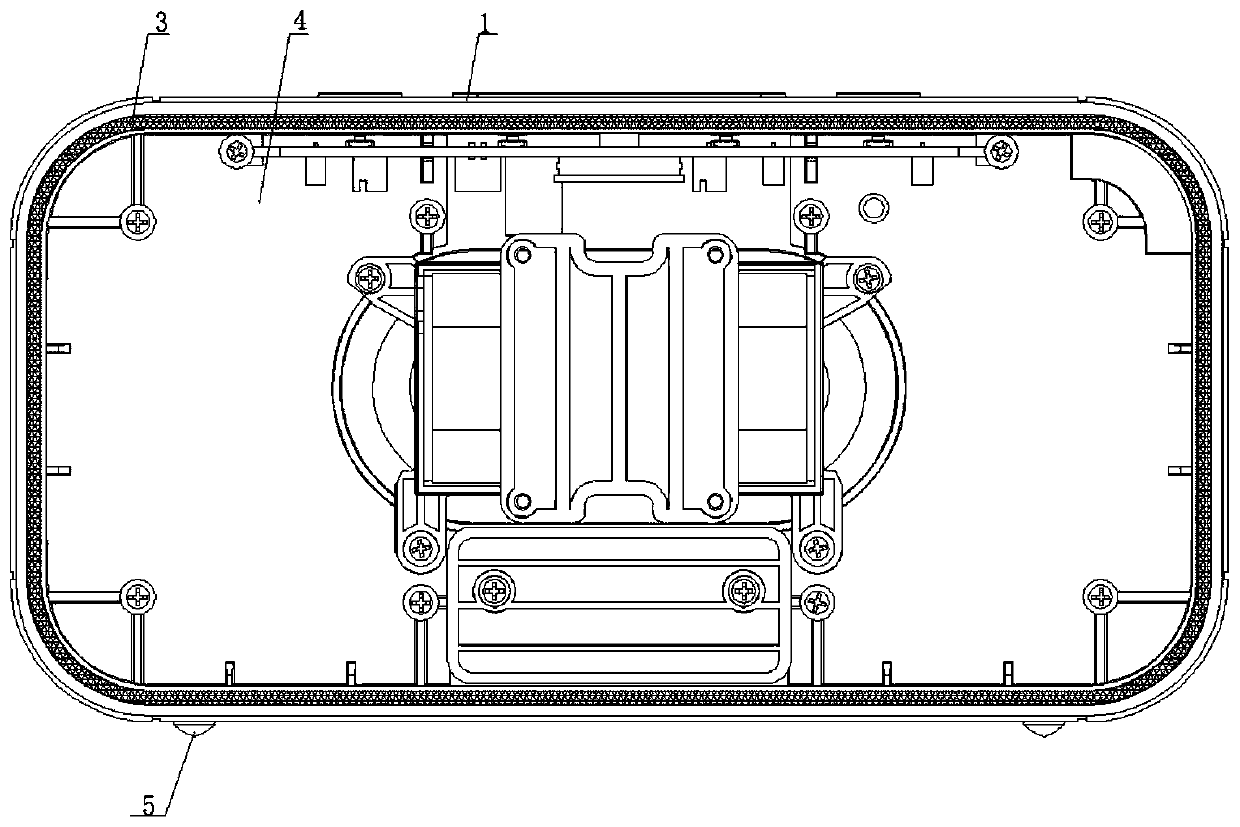

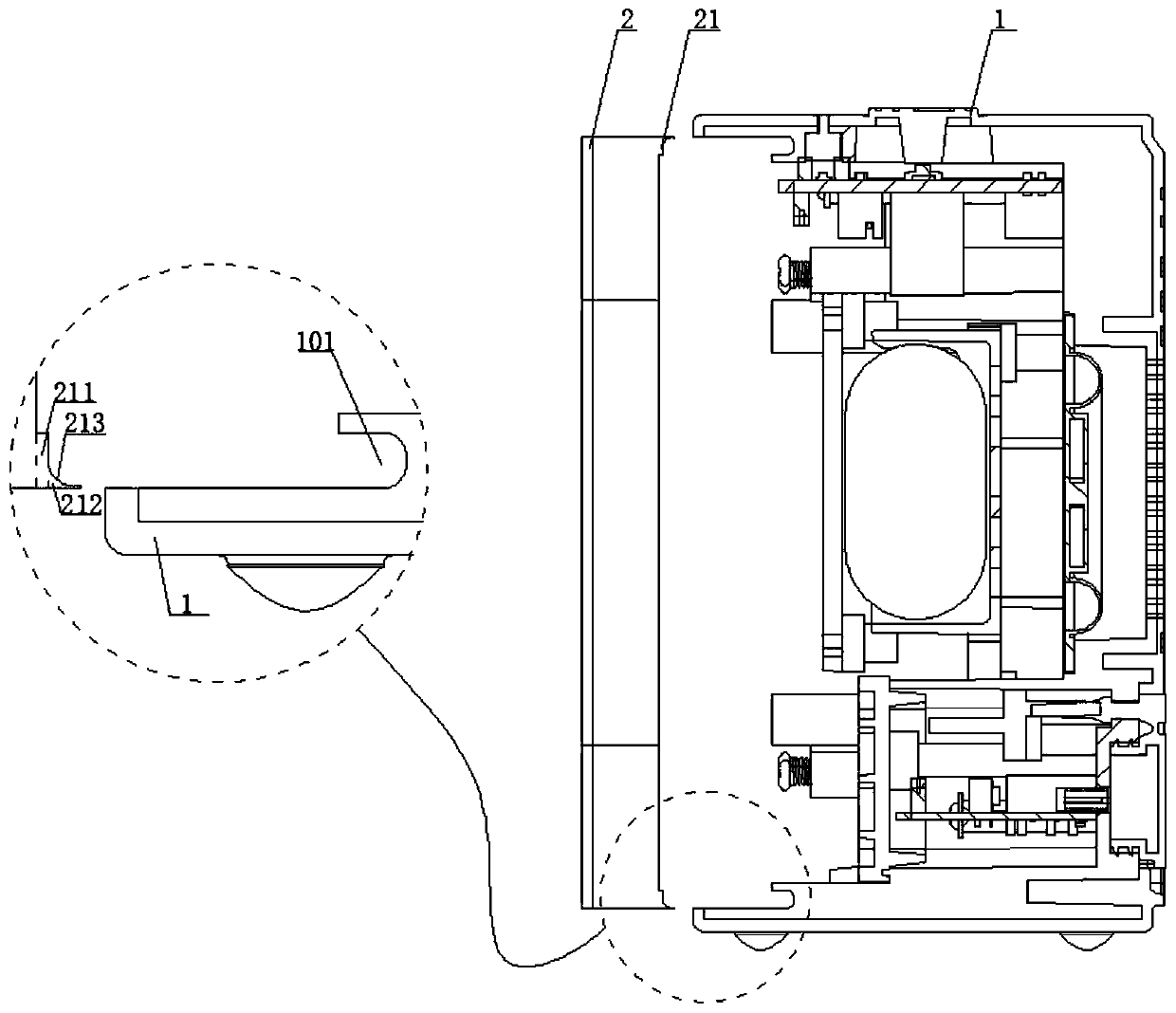

[0048] like figure 1 and figure 2As shown, Embodiment 1 of the present invention discloses a waterproof sound, comprising a box body 1 and a back plate 2;

[0049] The box body 1 is provided with a waterproof groove 101, and the waterproof groove 101 is located at the corresponding installation position of the box body 1 and the back plate 2, and at least a part of the back plate 2 is embedded in the waterproof groove 101;

[0050] Also includes a sealant 3, the sealant 3 is filled in the waterproof groove 101;

[0051] When the back plate 2 is installed on the box body 1 , the sealant 101 forms a seal at the gap where the box body 1 and the back plate 2 are connected.

[0052] Specifically, the cabinet 1 and the back panel 2 of the speaker are detachable assemblies. Water will enter the interior of the speaker through the gap after assembly, resulting in damage to the interior of the speaker. Therefore, the connection between the cabinet 1 and the back panel 2 The end pos...

Embodiment 2

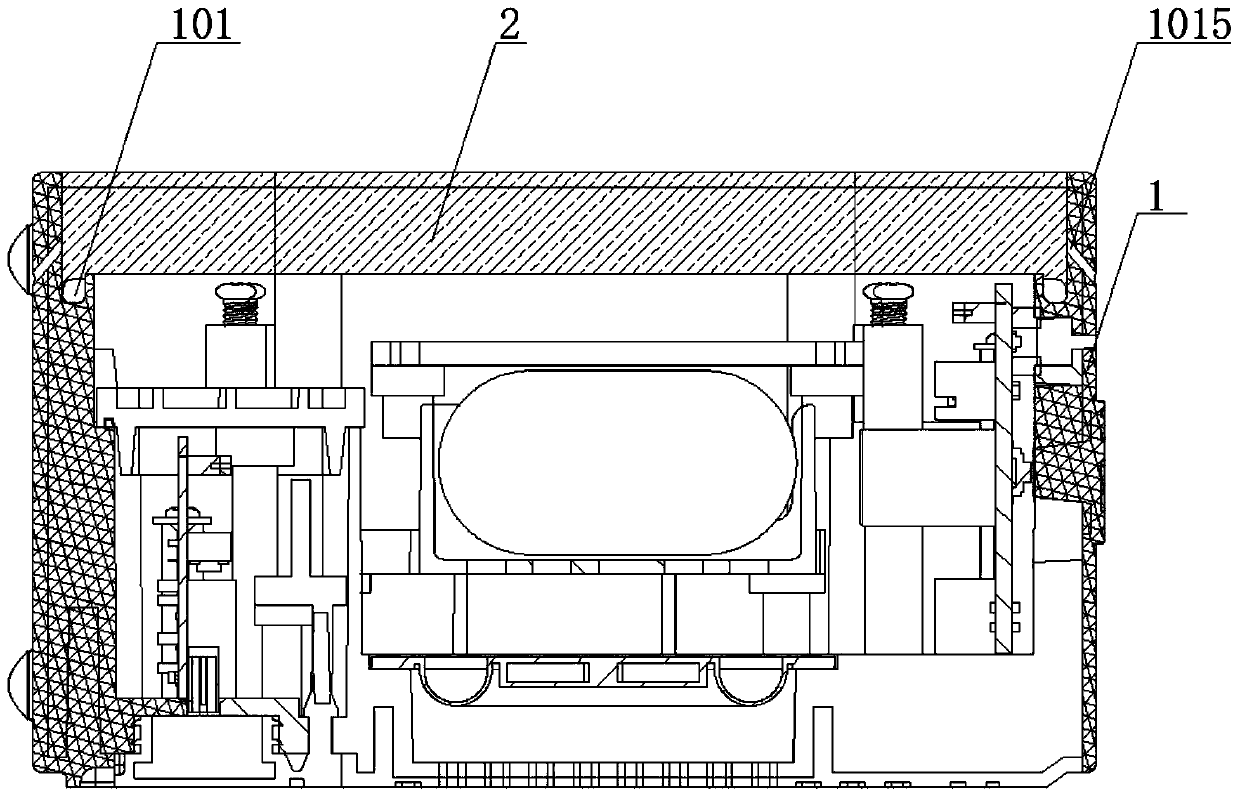

[0063] The waterproof sound of Example 2 of the present invention is improved on the basis of Example 1, such as image 3 and Figure 4 shown:

[0064] Preferably, the waterproof groove 101 includes a first side wall 1011 and a second side wall 1012, and the distance from the second side wall 1012 to the outer wall of the box 1 on the same side is smaller than that from the first side wall 1011 to the The distance between the outer walls of the box 1 on the same side, the second side wall 1012 is provided with a drainage inlet 1013, and the drainage inlets 1013 are arranged at preset intervals along the length direction of the waterproof groove 101, the The drainage inlet 1013 is above the waterproof groove 101 , and the distance from the drainage inlet 1013 to the bottom of the waterproof groove 101 is greater than the distance from the front end of the mounting portion 21 to the waterproof groove 101 . The drainage outlet 1014 is located in the direction from the drainage ...

Embodiment 3

[0078] The waterproof audio of Example 3 of the present invention is improved on the basis of Example 1, such as Figure 7 , Figure 8 and Figure 9 shown:

[0079] Preferably, the sound box further includes a plurality of foot pads 5 arranged on the bottom of the box body 1 .

[0080] Preferably, the foot pad 5 is an air spring foot pad, and a accommodating cavity 503 is provided in the air spring foot pad. The accommodating cavity 503 is filled with gas, and the air spring foot pad is used to buffer the sound produced by the sound. vibration.

[0081] Specifically, the foot pad 5 includes a mounting surface 501 and a contact surface 502, the mounting surface 501 and the contact surface 502 enclose an accommodation cavity 503 for accommodating elastic gas; the contact surface 502 is in contact with the ground, and the mounting surface 501 is installed On the bottom surface of the acoustic box 1, the accommodating cavity 503 is filled with air or inert gas.

[0082]In use...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap