Method for track position improvement by means of a track-movable track-tamping machine

A track position, tamping machine technology, applied in the direction of track, track maintenance, roads, etc., to avoid systematic errors, long durability, and high track position quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

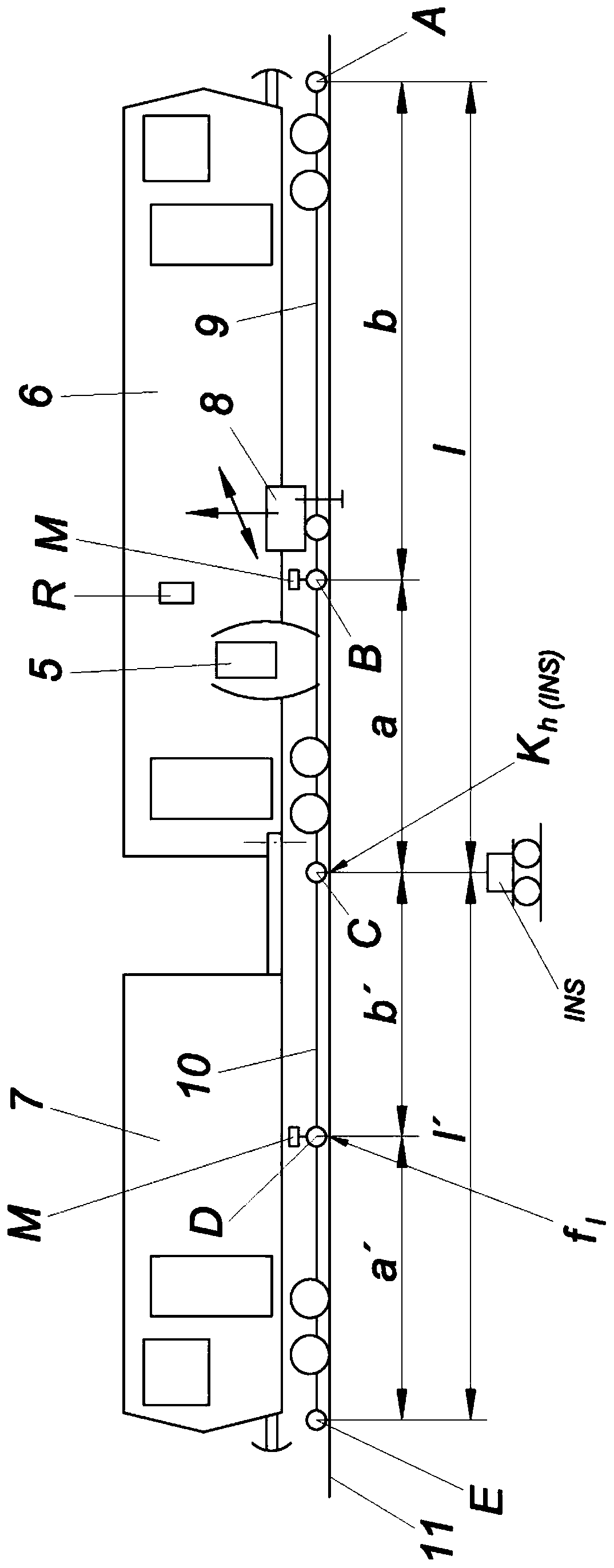

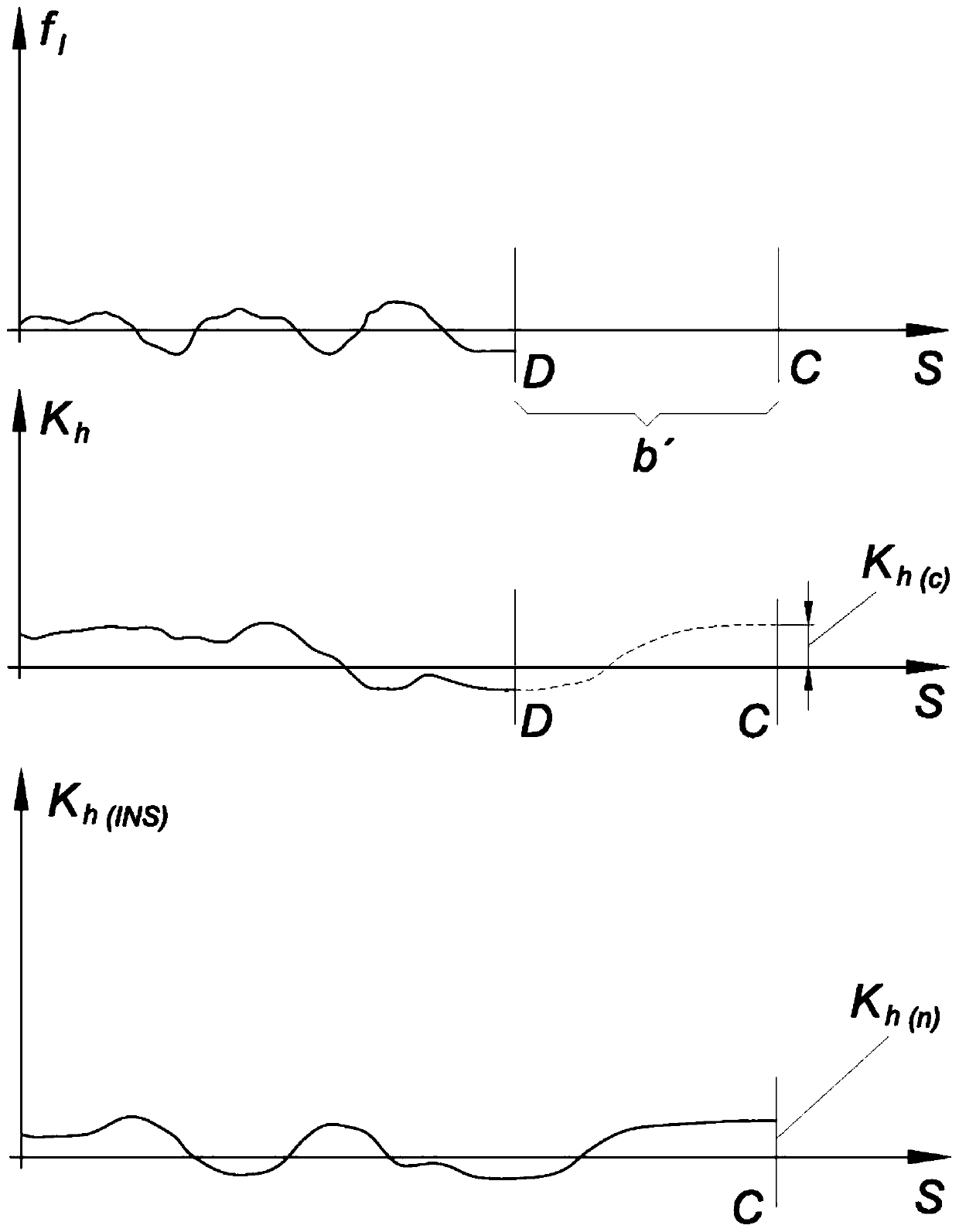

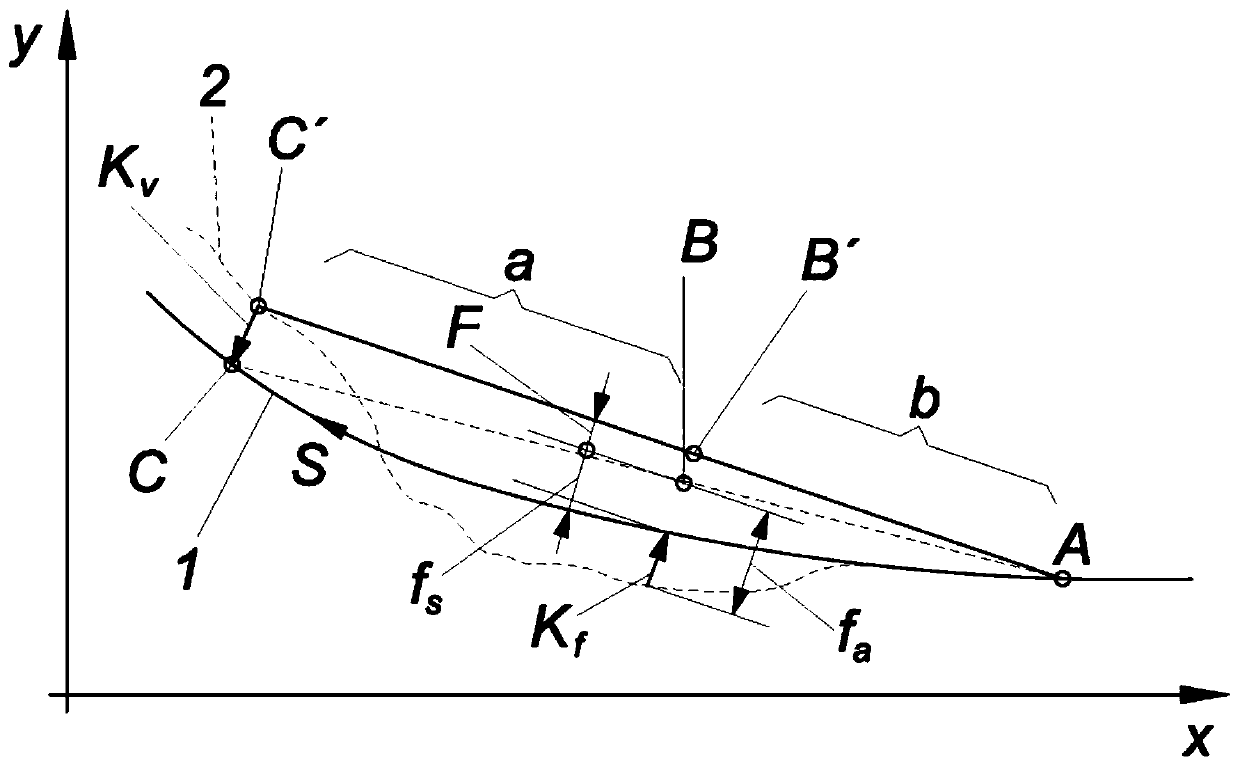

[0028] figure 1A rail tamping machine for carrying out the method according to the invention is shown. A trailer 7 is connected to the track tamping machine 6 . The track tamping machine 6 is equipped with a tamping unit 5 . The rail 11 is lifted and aligned by the lifting and correcting unit 8 into the target rail position which needs to be corrected with respect to its position in the gravel bed. Below the rail tamping machine 6 there is a three-point working measuring system with three measuring carriages A, B, C and strings 9 , for example steel strings, stretched between the measuring carriages. In the measuring cart B, the sensor M measures the heightwise and lateral deflection of the string 9 . The chord 9 has a length l and is divided into chord sections a and b, between which the measuring carriage B is arranged.

[0029] To verify the measurement, a test string 10 can be stretched between the measuring carriages E and C on the trailer 7 . In the measuring carria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com