Patents

Literature

30results about How to "Eliminate error factors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

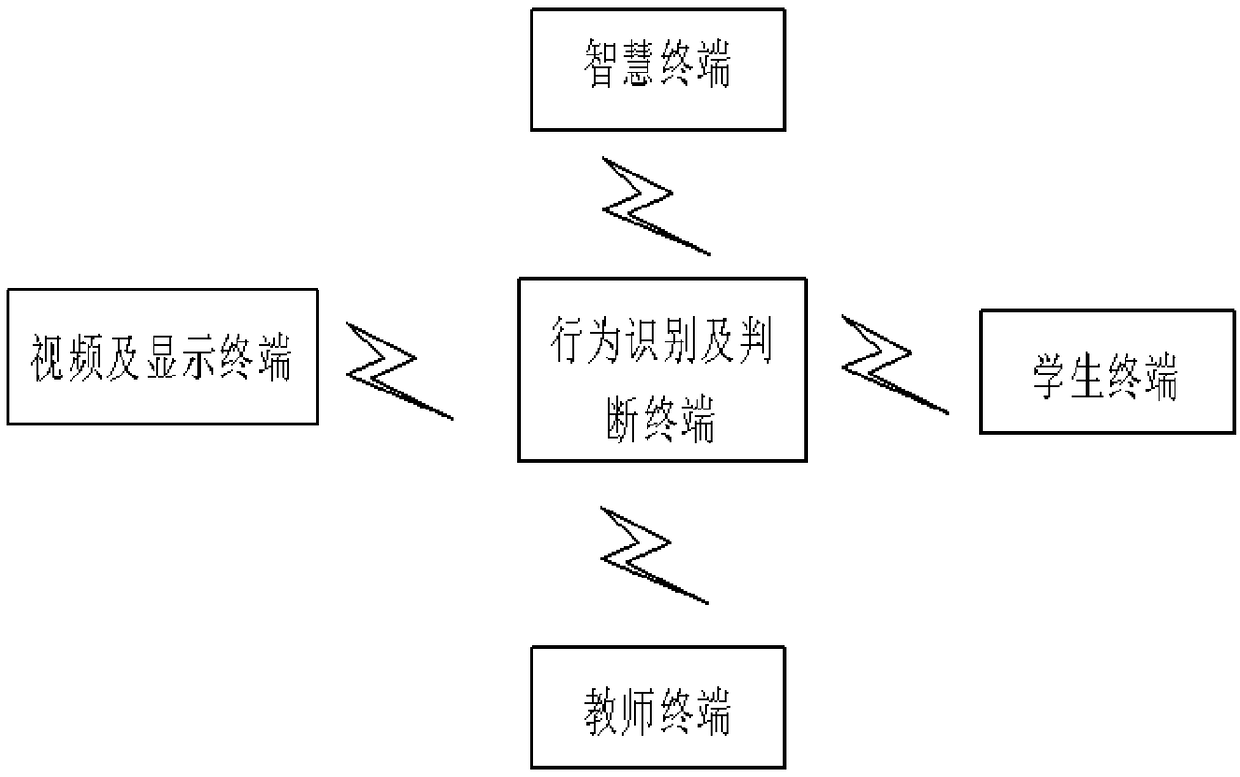

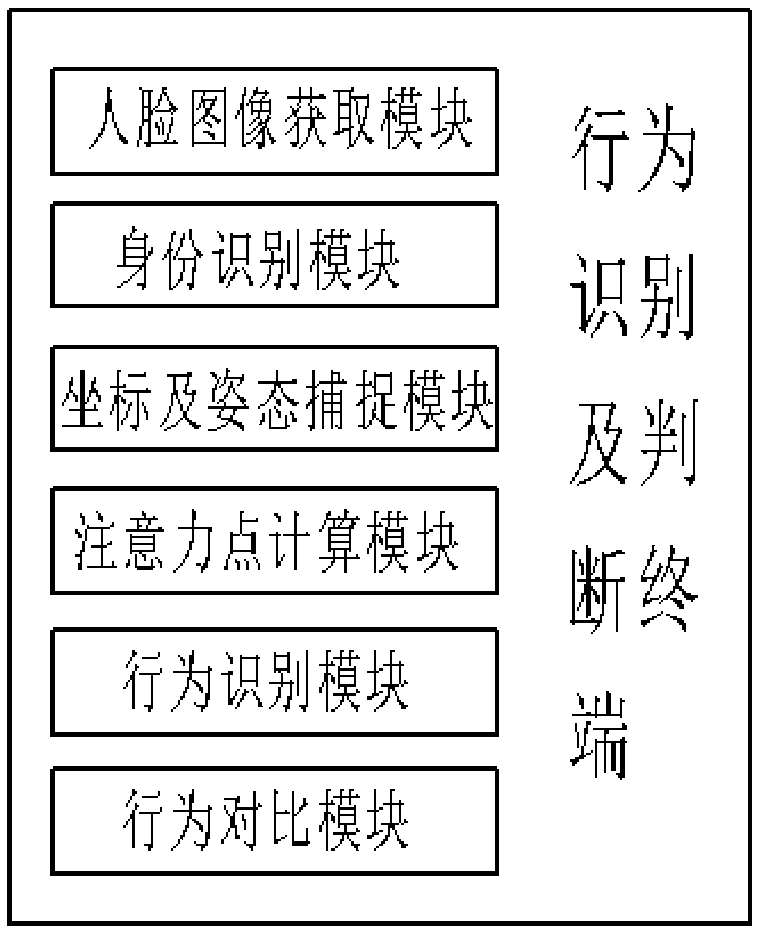

A student behavior analysis and identification system for a smart classroom

InactiveCN109284737AReduce mistakesEasy to identifyData processing applicationsCharacter and pattern recognitionHand movementsComputer science

The invention relates to the field of intelligent teaching, in particular to a student behavior analysis and identification system for an intelligent classroom. The system comprises a coordinate and posture capture module, which obtains the position coordinates of each student and captures the facial orientation posture and hand movement posture of each student. The attention point calculation module obtains the facial orientation posture of the students and calculates the classroom attention points of the students through the facial orientation posture; Behavior recognition module obtains students' attention points and hand gestures, and recognizes students' classroom behavior through students' classroom attention points and hand gestures; Behavior comparison module, to obtain the classroom behavior of each student, and compare with the classroom behavior of its neighboring students, to judge the classroom state of each student; the result feedback module is used to feedback the students' classroom state and feedback it to the teacher in real time. The present invention solves the problem that the prior art is inaccurate in identifying and judging the classroom state of students.

Owner:GUANGZHOU JINGBIAO INFORMATION TECH CO LTD

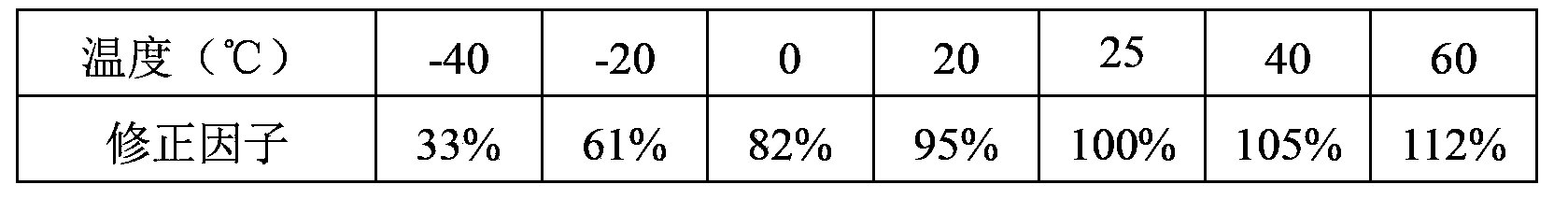

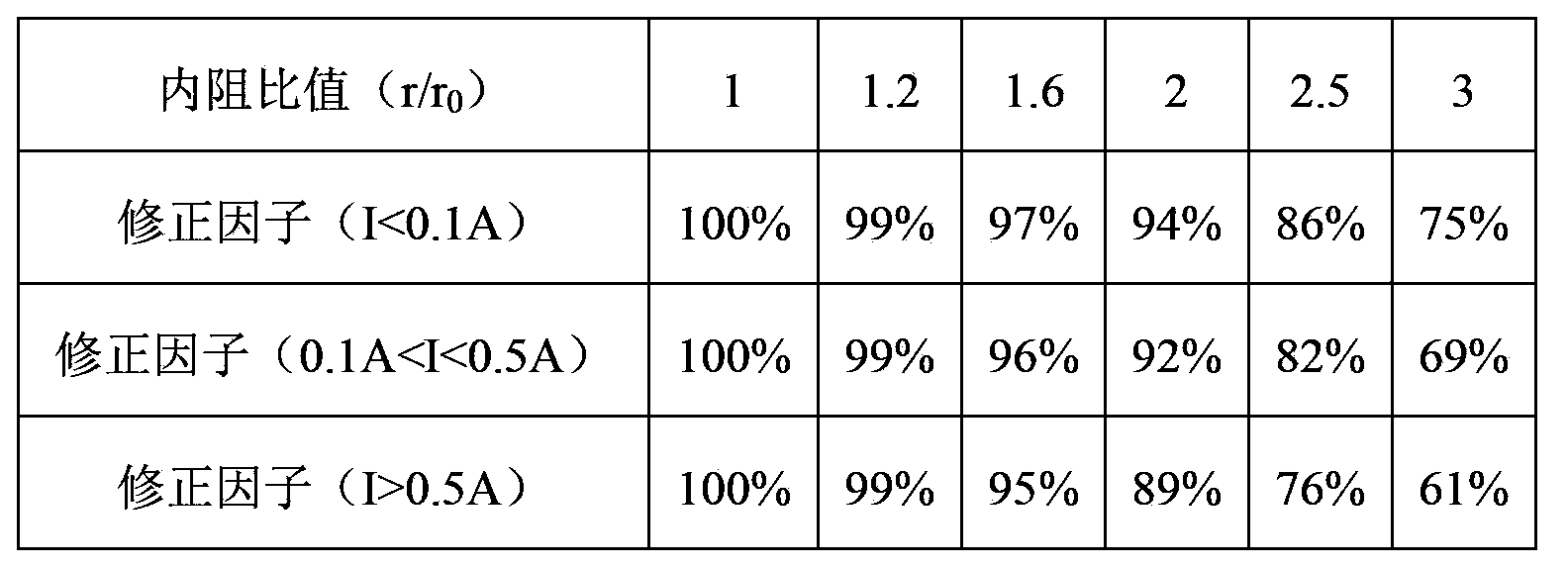

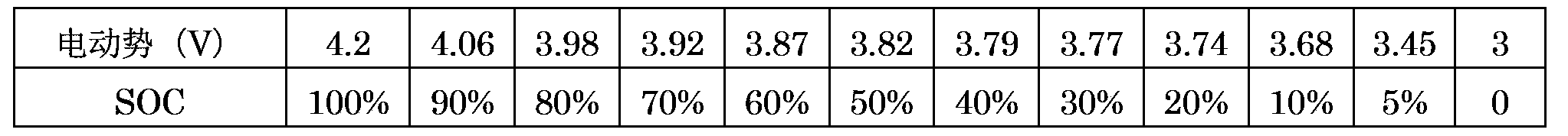

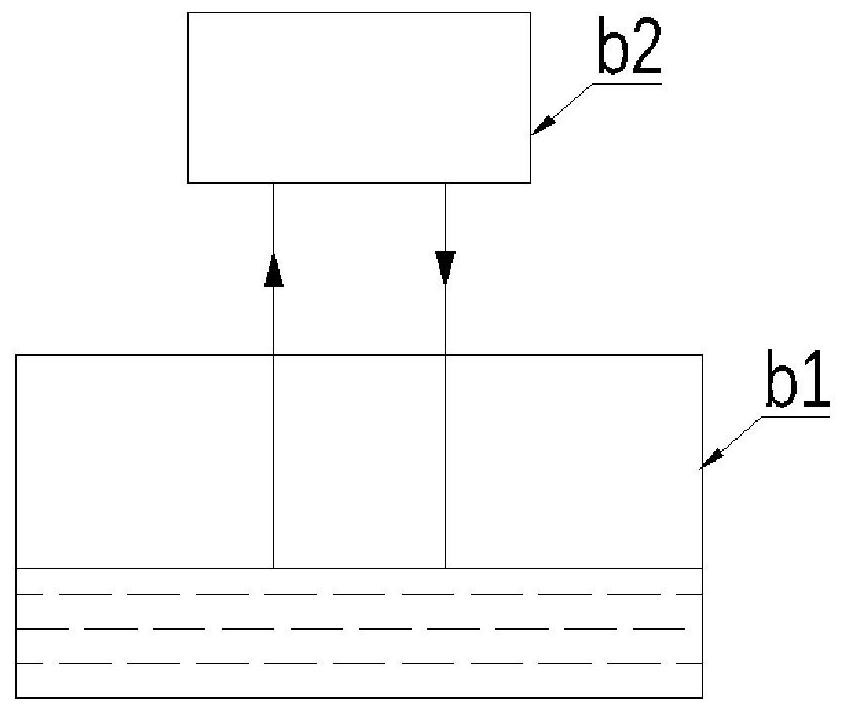

System and method for on-line dynamic measurement of electric quantity of lithium ion batteries

InactiveCN103383435AEliminate error factorsReduce measurement errorElectrical testingReal-time dataTerminal voltage

The invention provides a system for measuring the electric quantity of lithium ion batteries. The system is used for on-line dynamic measurement and correction of the electric quantity of the lithium ion batteries at work to reduce measuring errors. The system for measuring the electric quantity of the lithium ion batteries is characterized by comprising a voltage and current acquisition module, a temperature acquisition module, a processing module, a display module and a voltage stabilizing circuit. The voltage and current acquisition module is used for acquiring terminal voltage and main line current data of N storage battery sets at the same time point and transmitting the terminal voltage and main line current data to the processing module; the processing module conducts least squares fit on the terminal voltage and main line current data, a U-I curve is obtained, and the electromotive force epsilon and the internal resistance r of the lithium ion batteries are obtained through calculation; internal temperature data of the lithium ion batteries are acquired at regular time; the state of charge of the lithium ion batteries is obtained in a partition linear processing mode according to the electromotive force epsilon of the lithium ion batteries; burn-in correction and temperature correction are conducted on the state of charge respectively in a partition linear processing mode according to the internal resistance r and internal temperature T of the lithium ion batteries, and therefore real-time data of the electric quantity of the lithium ion batteries at the time point are obtained.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

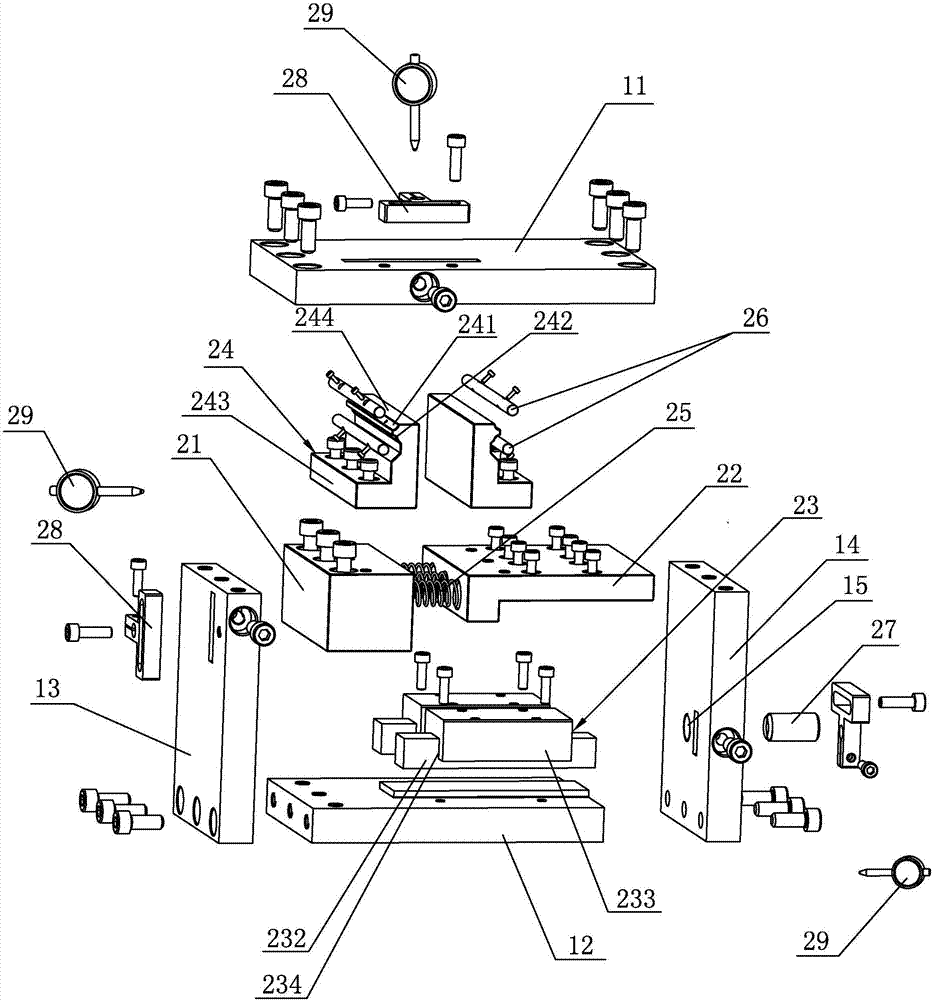

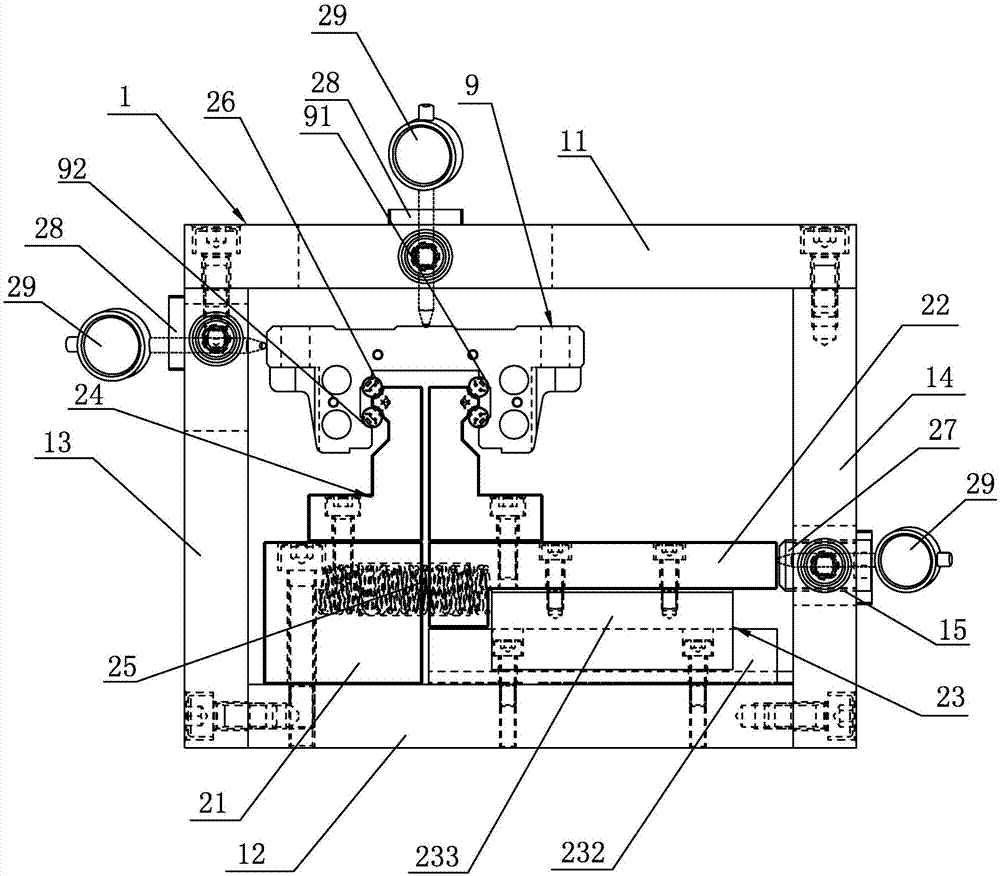

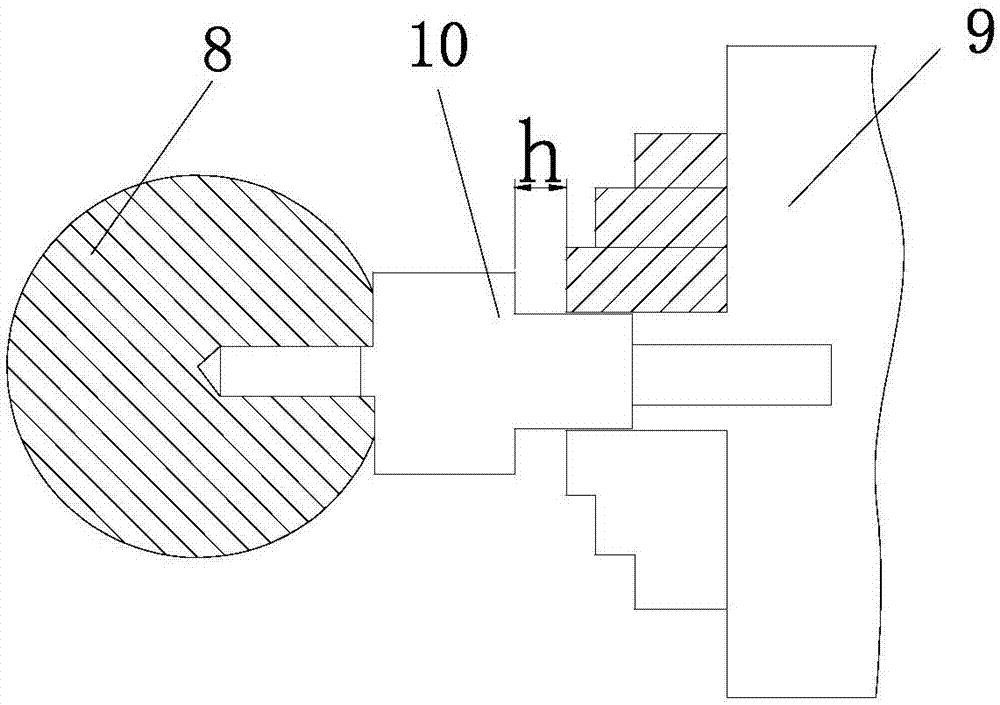

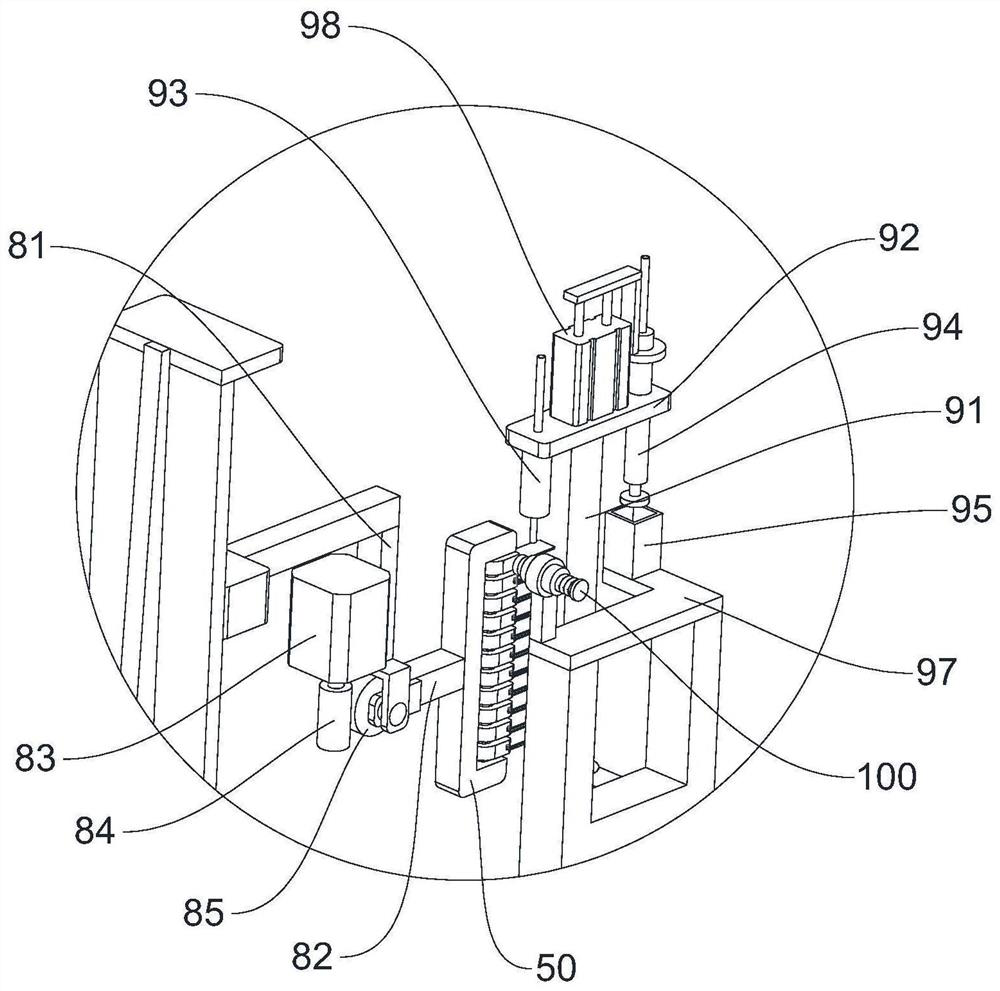

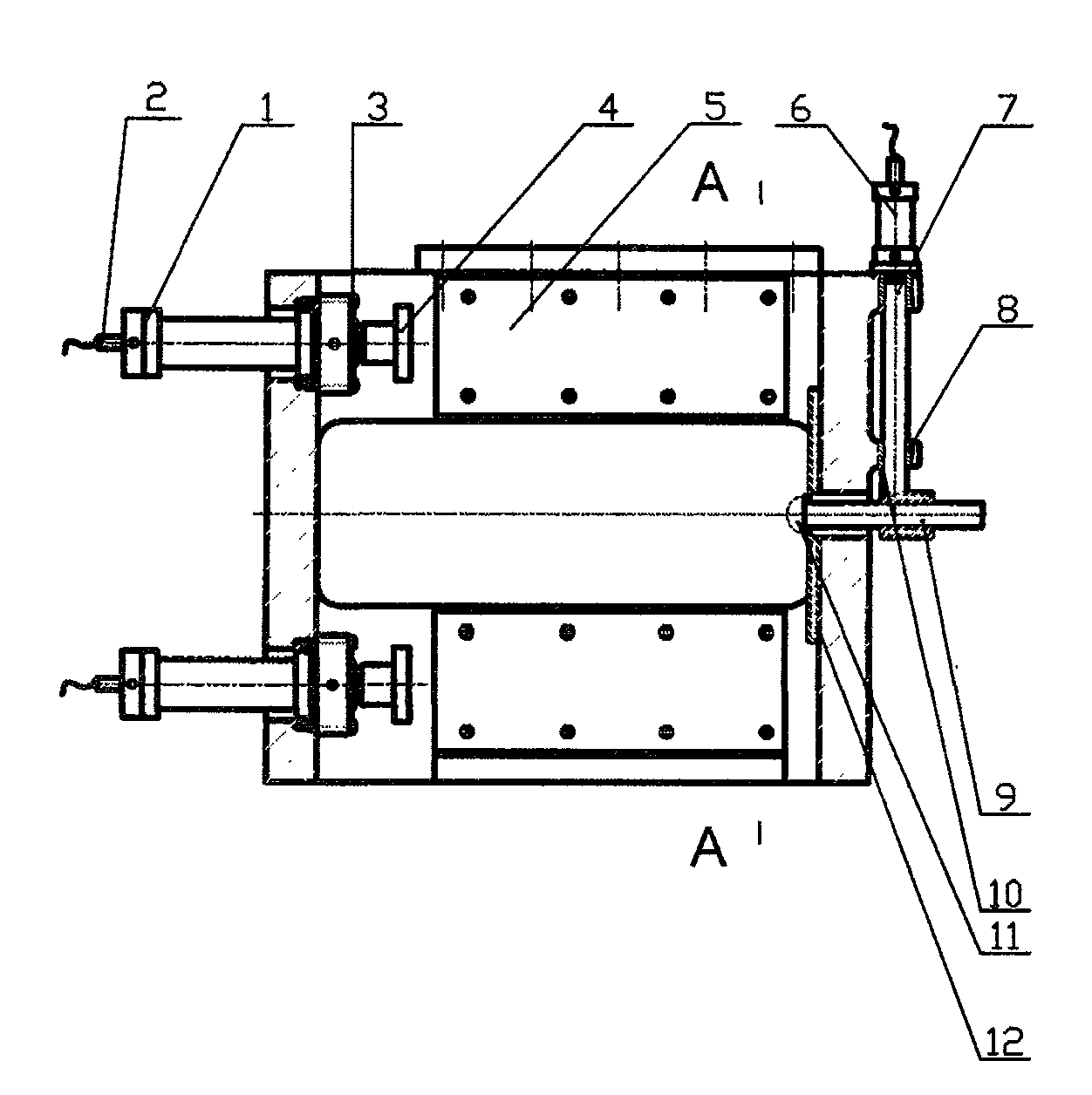

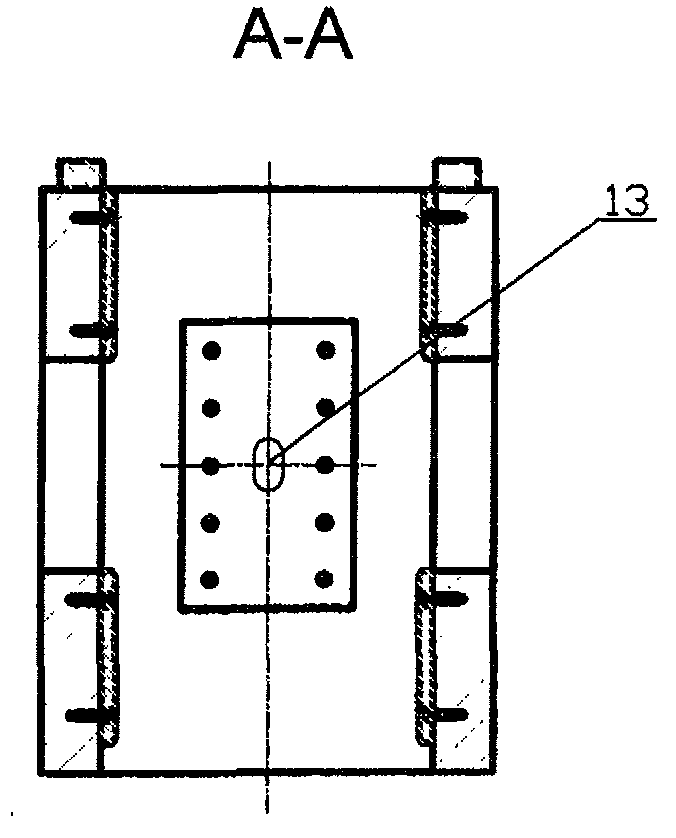

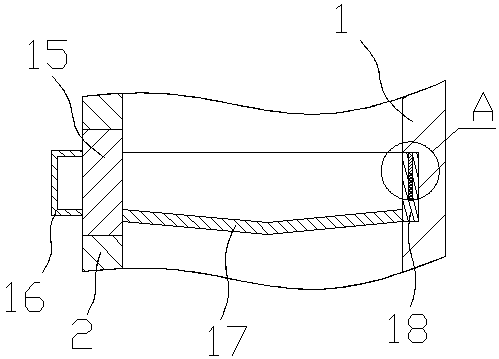

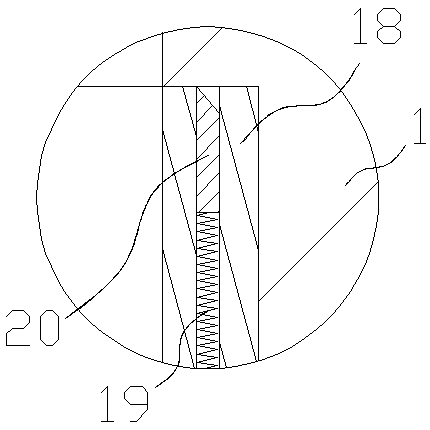

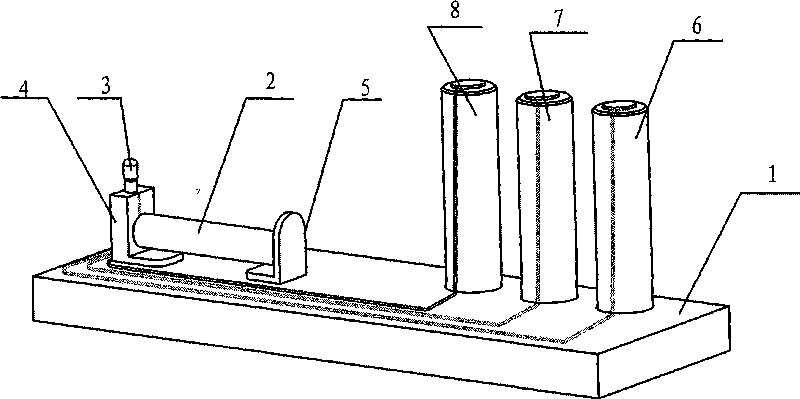

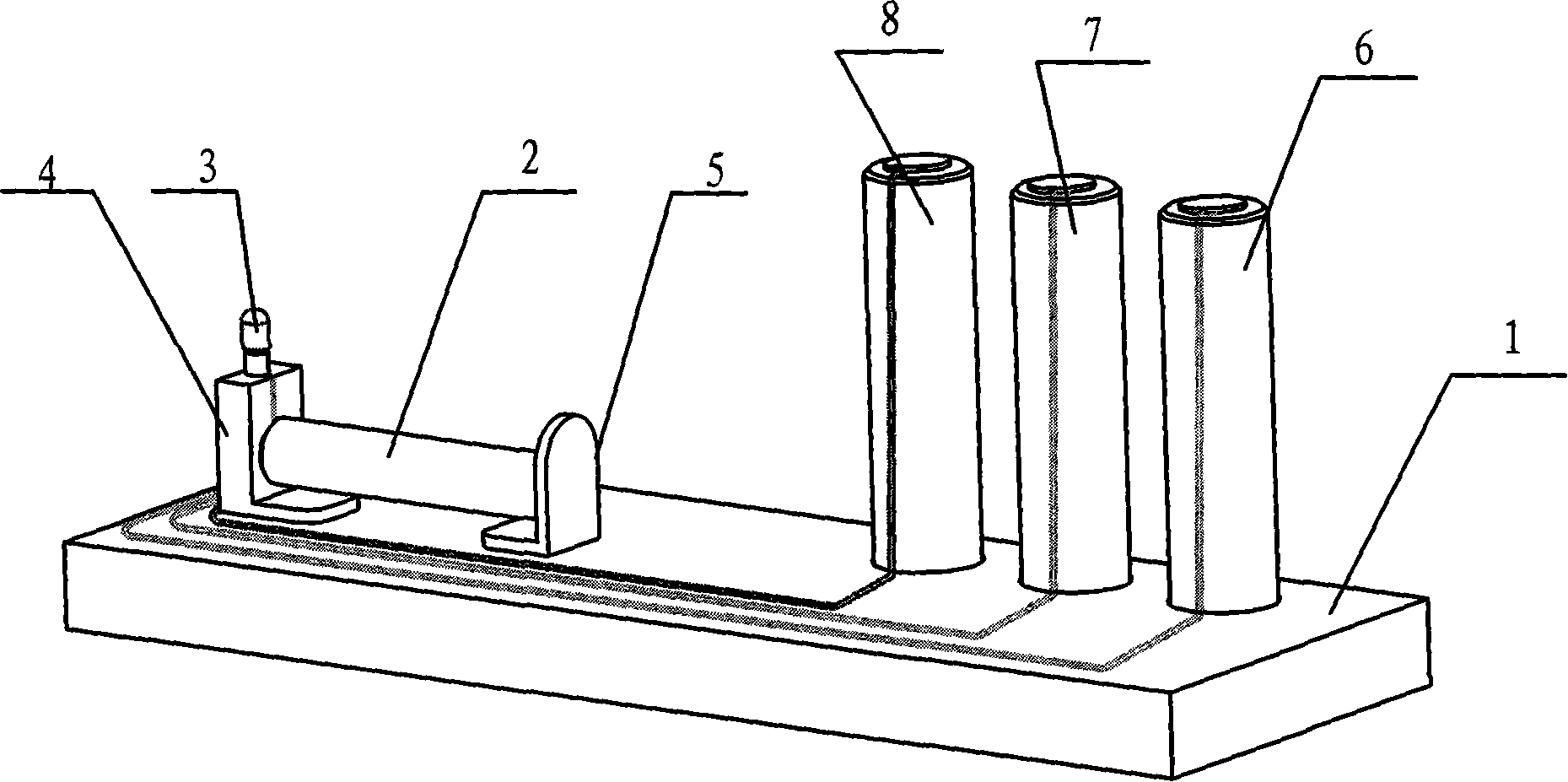

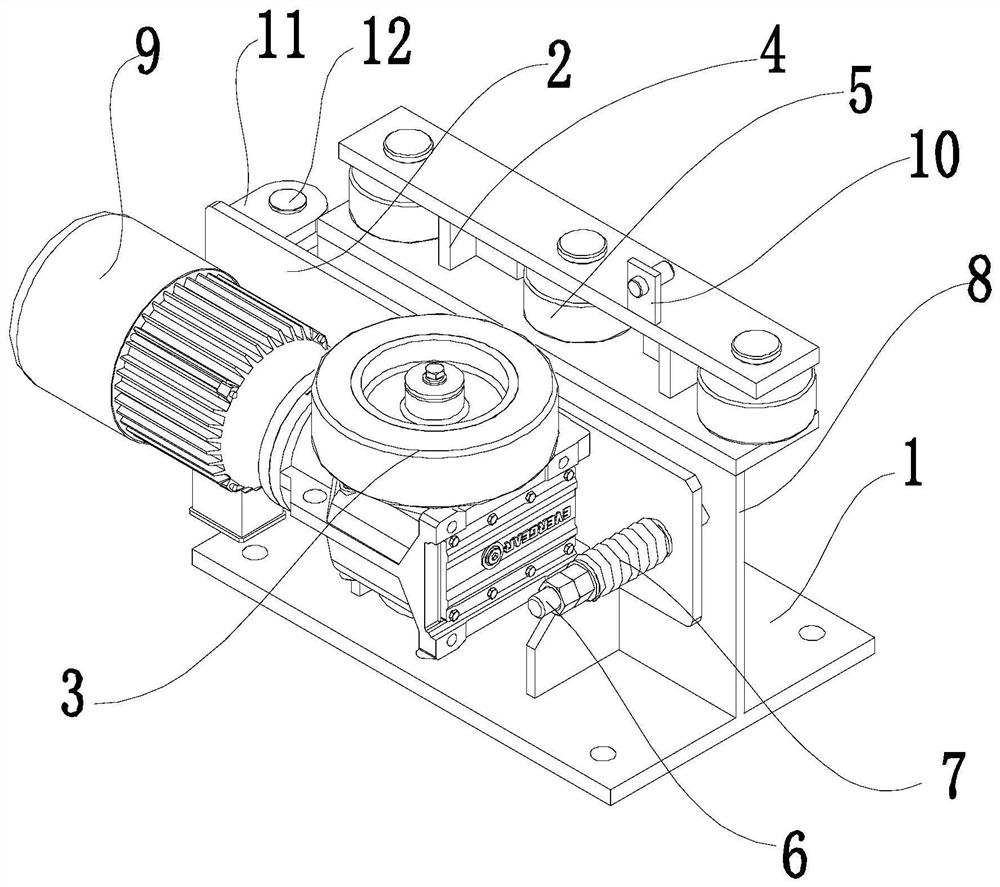

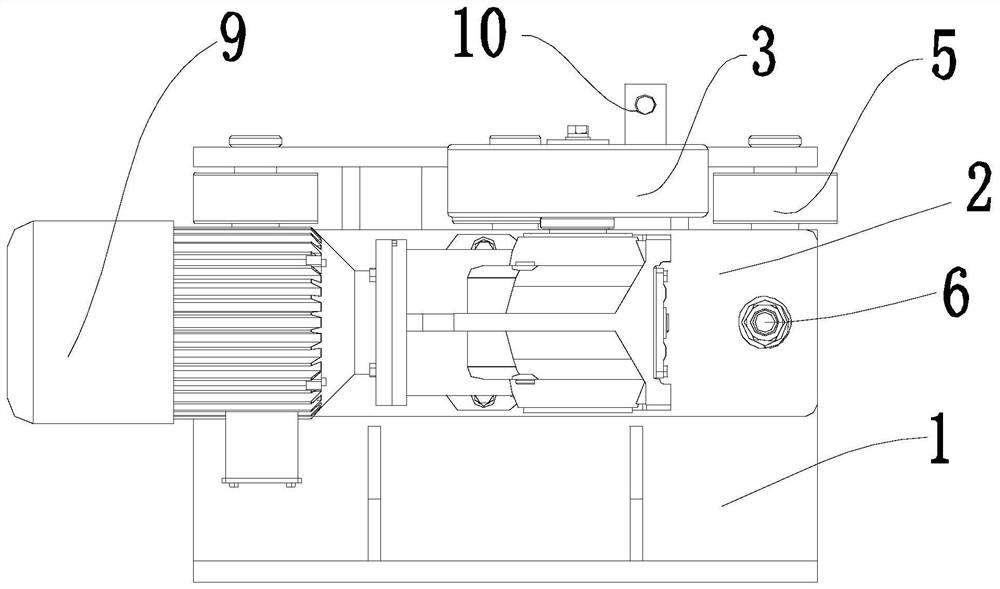

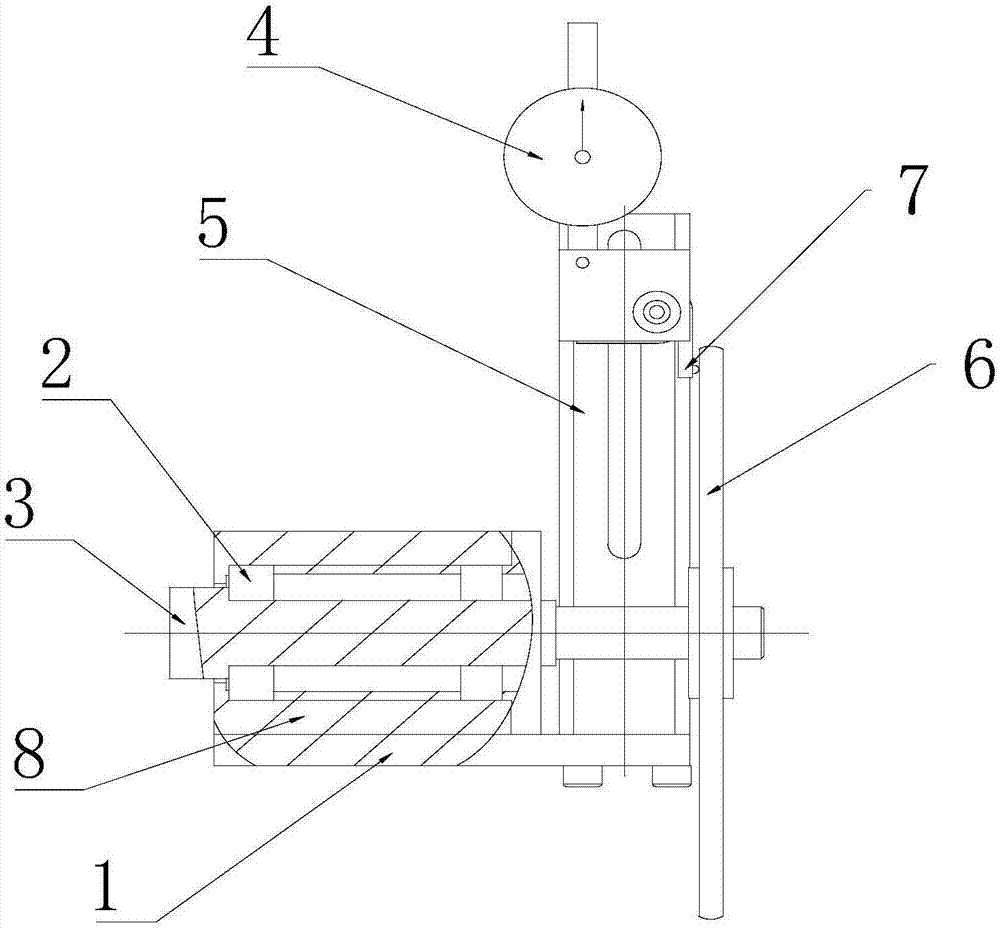

Ball slide block measuring device and method

ActiveCN106871760AHigh measurement accuracyEliminate error factorsMechanical measuring arrangementsMeasurement deviceStructural engineering

The invention discloses a ball slide block measuring device and method. The measuring device comprises a rectangular frame and a slide block positioning assembly, the slide block assembly is composed of a fixed seat, a mobile seat, a mobile auxiliary member and two measuring heads, the two measuring heads are arranged on the fixed seat and the mobile seat symmetrically, the fixed seat is fixed in the left side of the internal bottom side of the rectangular frame, the mobile auxiliary member is mounted in the right side of the internal bottom side of the rectangular frame, the mobile seat is arranged on the mobile auxiliary member, a pressure spring is arranged between the fixed seat and the mobile seat, the external surface in the upper portion of each measuring head is provided with upper and lower arc chutes corresponding to upper and lower raceways of a ball slide block, the upper and lower arc chutes are provided with measuring rods whose radius is the same with that of a ball respectively, a fastening screw which enables the mobile seat to move left and right is arranged in the right side of the rectangular frame, the upper and lower measuring rods are fit to the corresponding upper and lower raceways under effect of the pressure spring, measuring tool locking seats are mounted in top, left and right sides of the rectangular frame respectively, and dial gauges are mounted on the measuring tool locking seats respectively. The measuring device and method have the advantages that the measuring efficiency can be improved, and many error factors can be eliminated to improve the measuring precision.

Owner:宁波海迈克精密机械制造有限公司

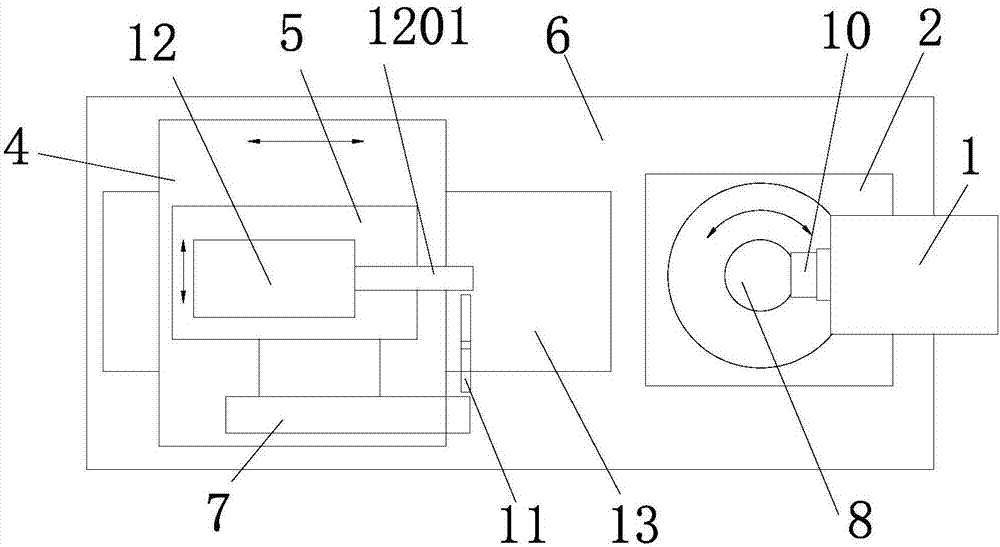

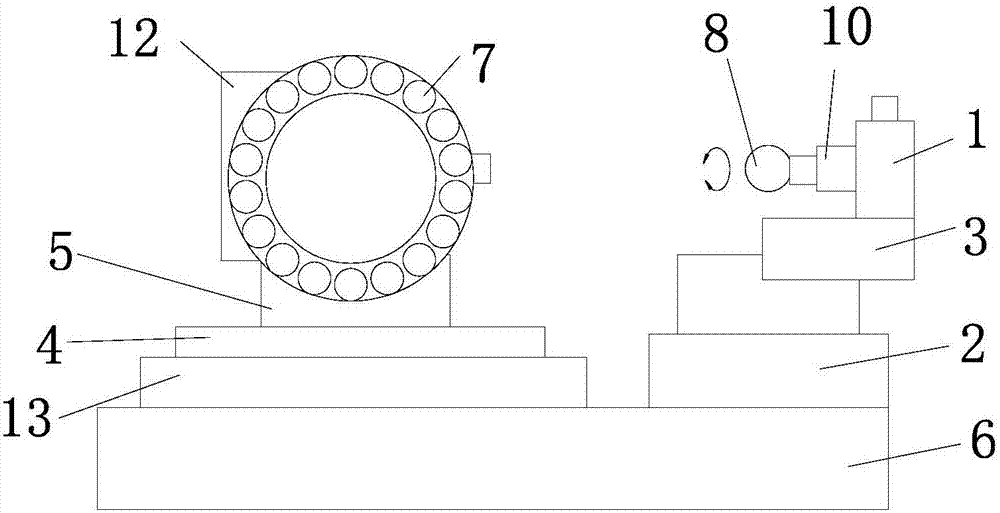

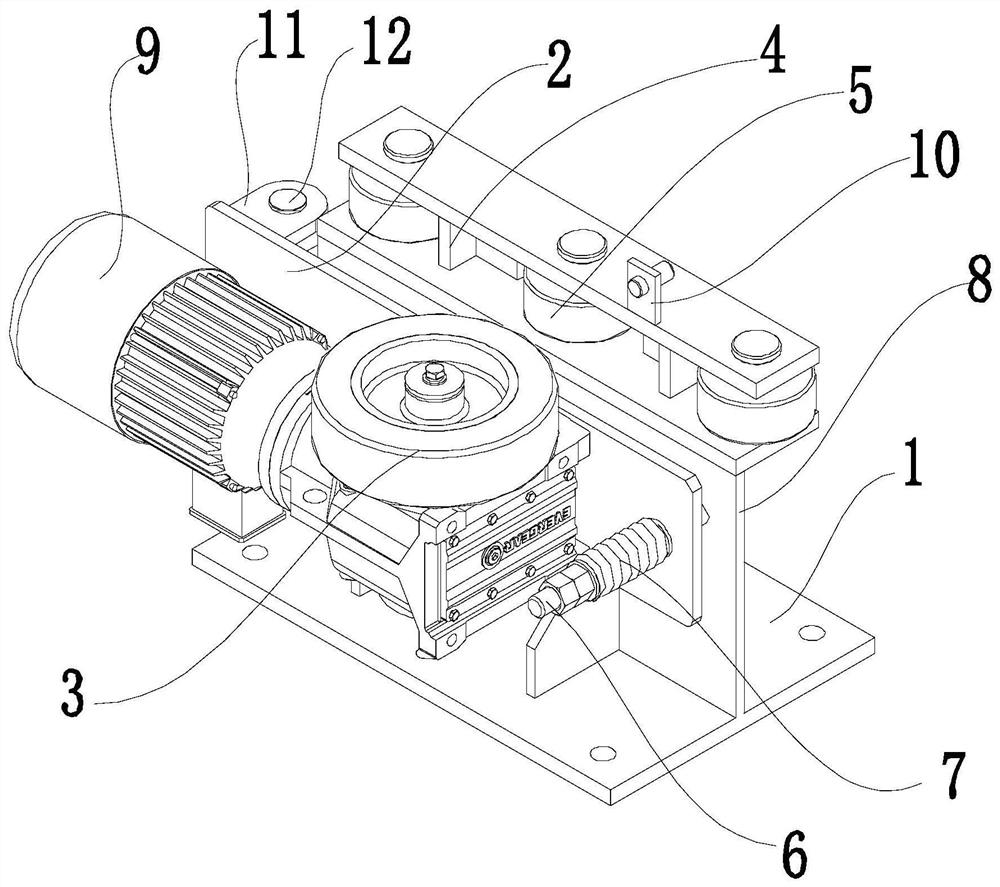

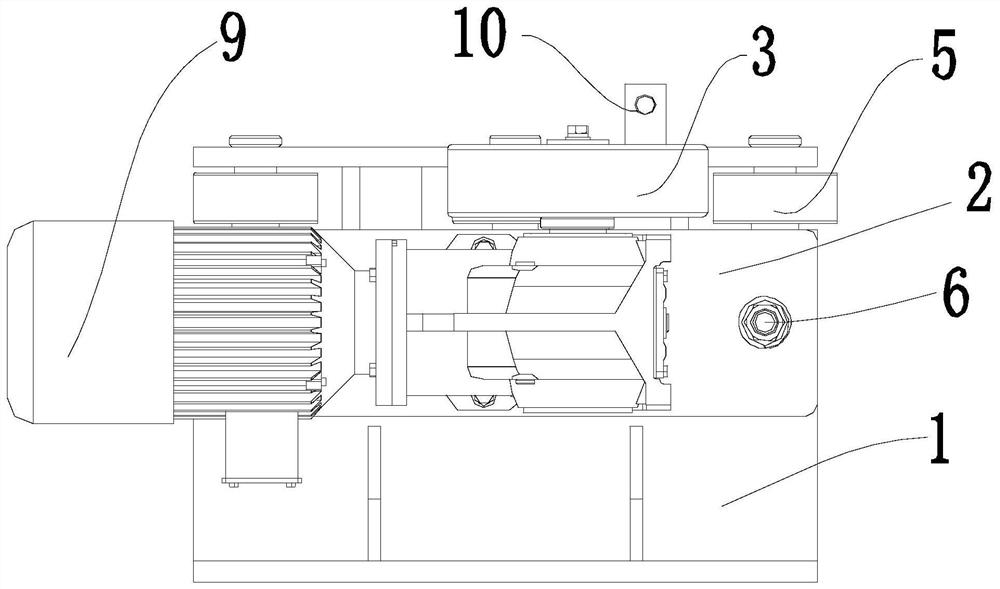

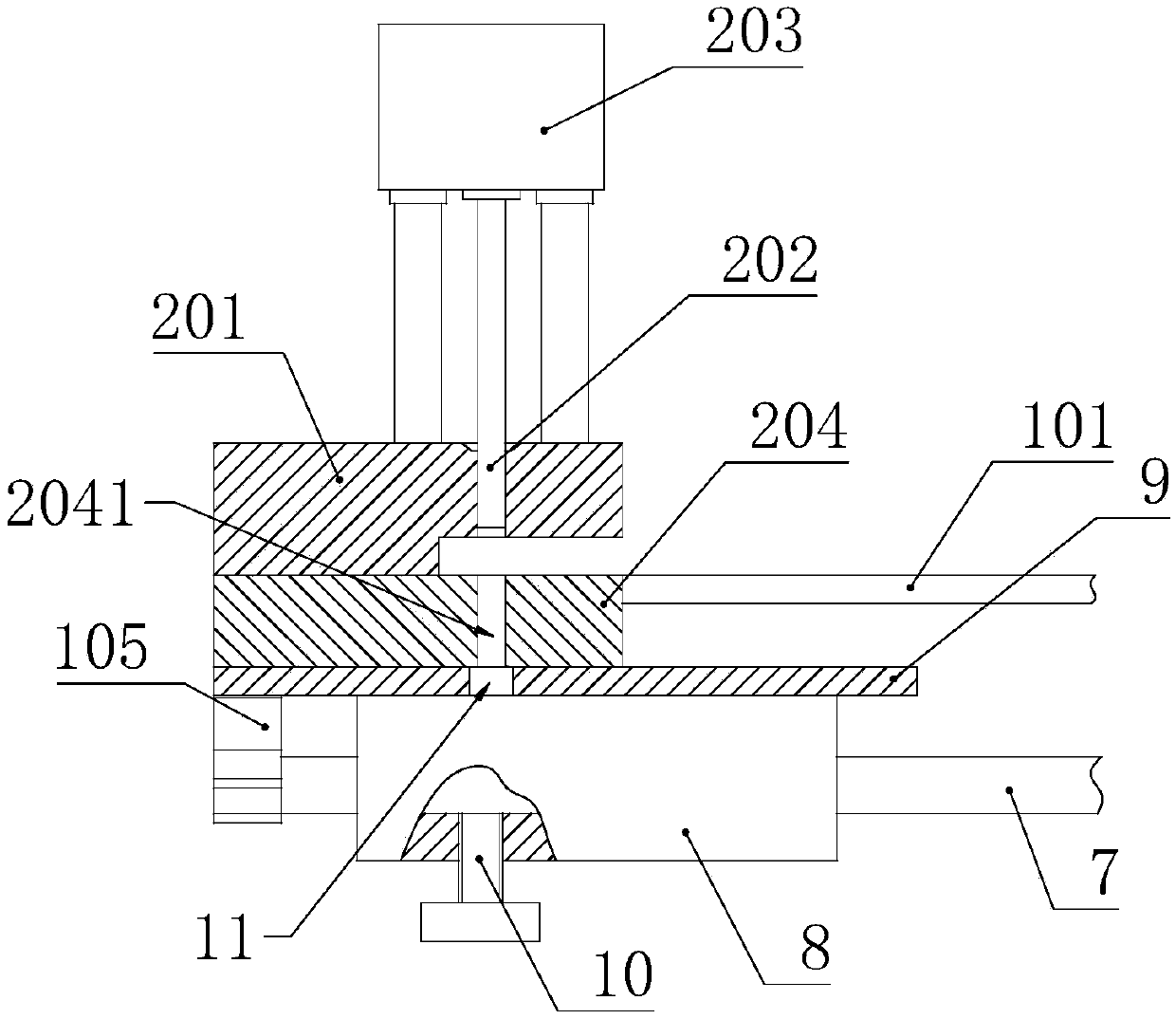

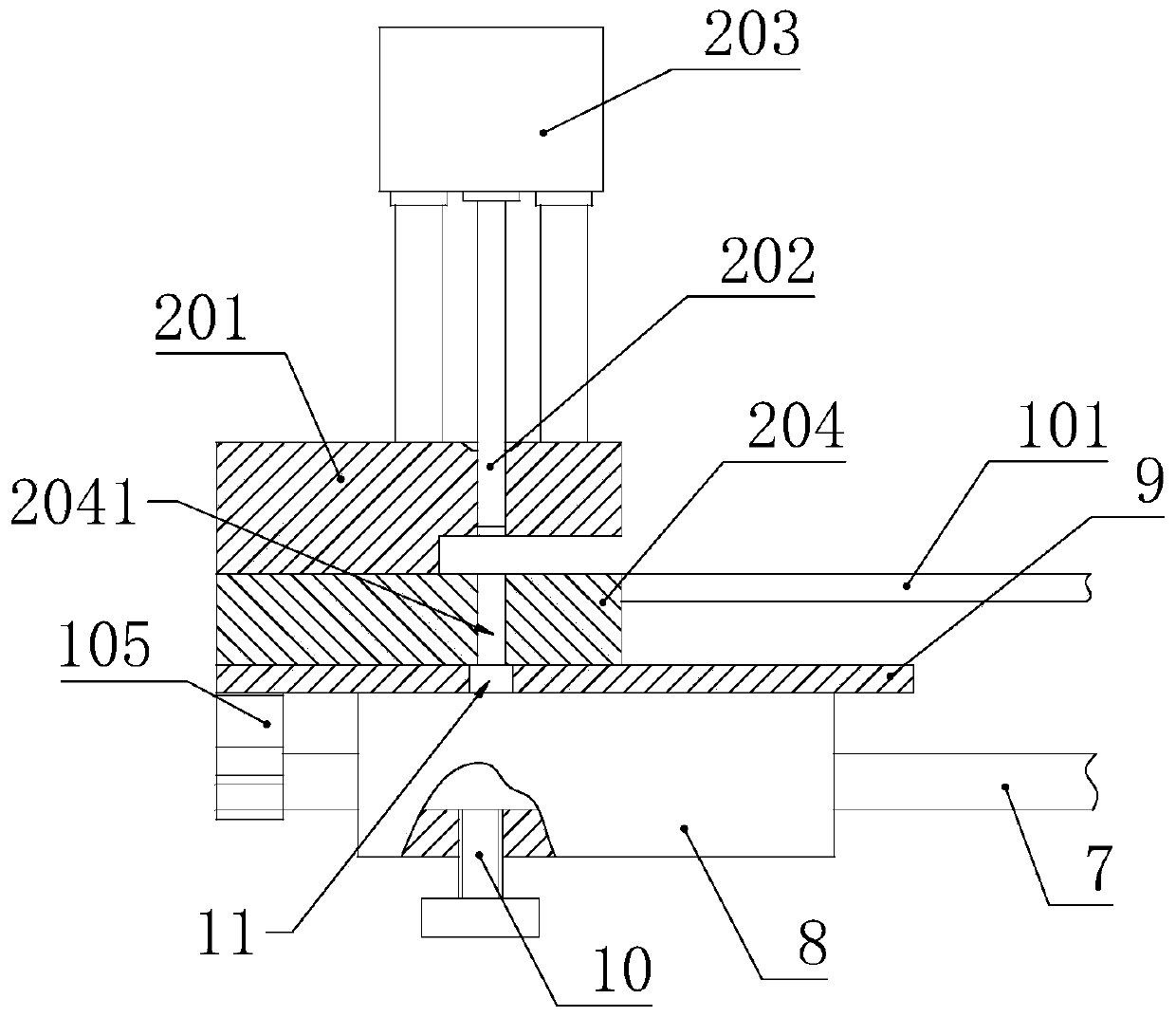

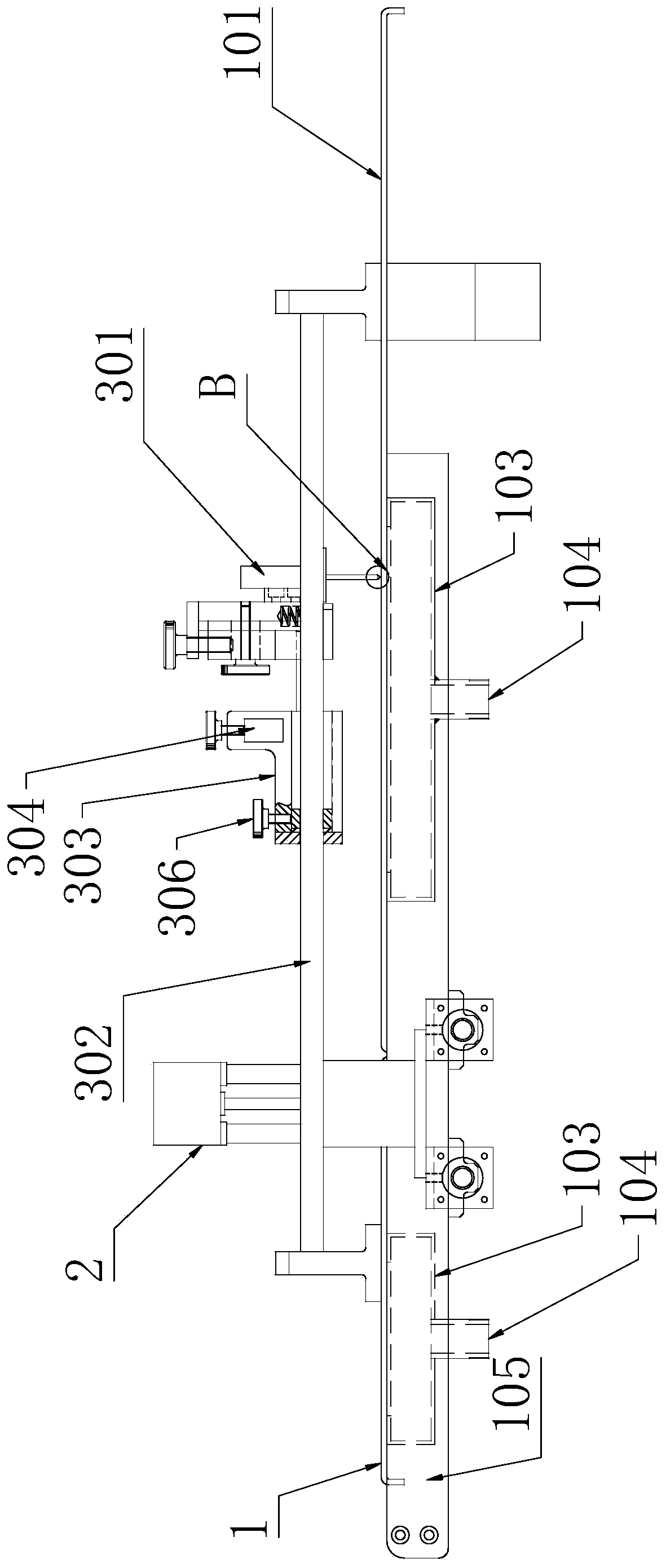

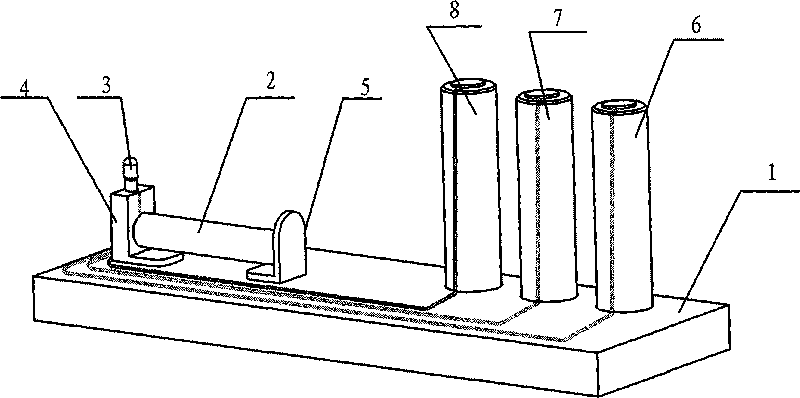

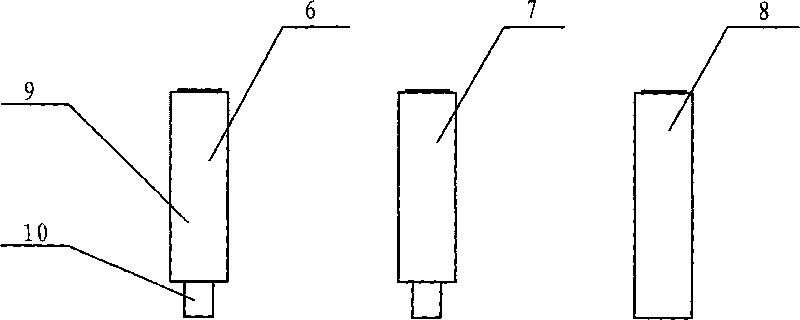

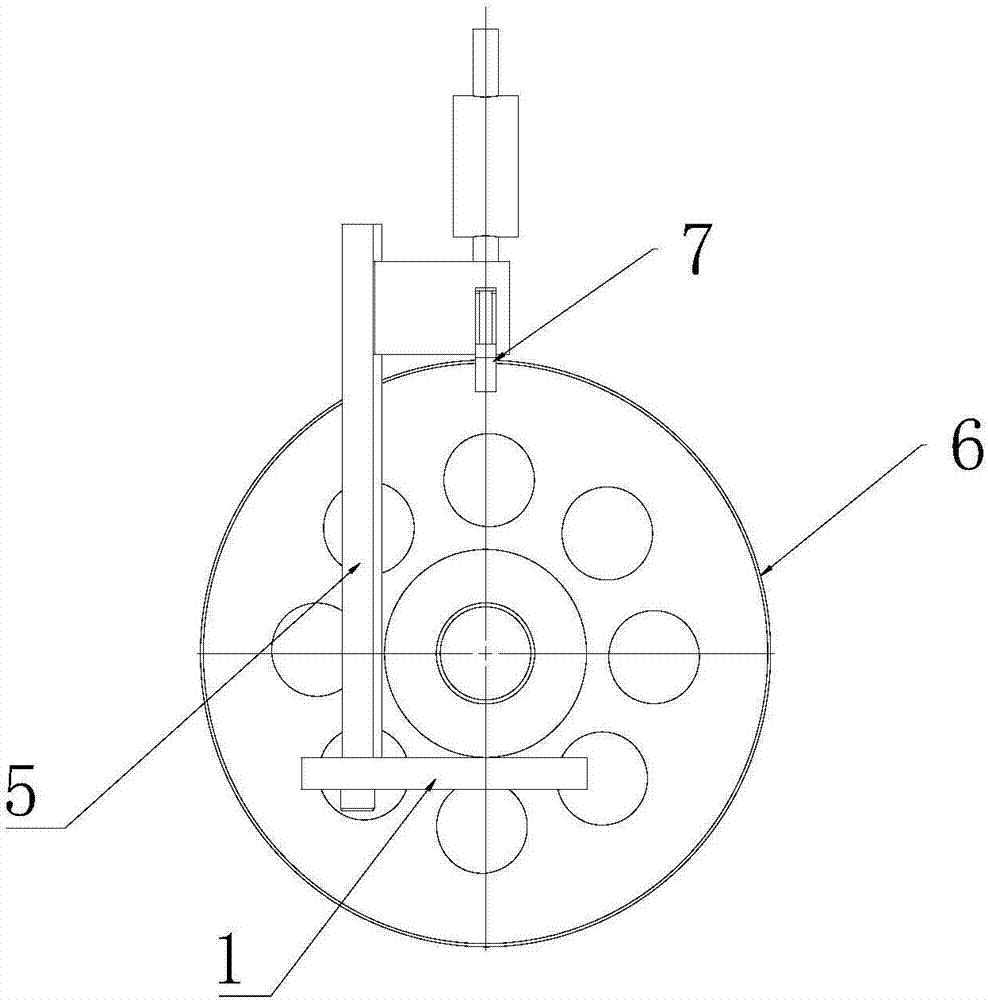

Machining center machine tool and machining method specially for horizontal type bolted sphere

InactiveCN107962192AReduce manufacturing costIncrease stiffnessOther manufacturing equipments/toolsLarge fixed membersCircular discError factor

The invention discloses a machining center machine tool and machining method specially for a horizontal type bolted sphere. The machining center machine tool and machining method specially for the horizontal type bolted sphere comprises a cross side way, a horizontal sliding table, a longitudinal sliding table, a base, and a horizontal type circular tool magazine; and the cross side way is arranged on the plane of the base and is provided with the horizontal sliding table, the longitudinal sliding table is arranged on the upper end of the horizontal sliding table, the horizontal type circulartool magazine is arranged at one end of the longitudinal sliding table and is characterized by comprising a four-axis feed system and a tool changing system, and the four-axis feed system comprises aturntable system, a horizontal sliding table, and a longitudinal sliding table. The main design is the sphere center of the bolted sphere being a machining benchmark, without or reducing fixture changing, each of error factors caused by an unfixed sphere center is eliminated, machining accuracy is enhanced significantly, the sensibility of an initial position during machining is reduced, force isuniform and reliable, and rigid maintenance performance is good; and the sphere center of the bolted sphere is a reliable functional unit for design and modifying of a horizontal type machine tool ofthe bolted sphere.

Owner:HENAN TIANYUAN SPACE FRAME CO LTD

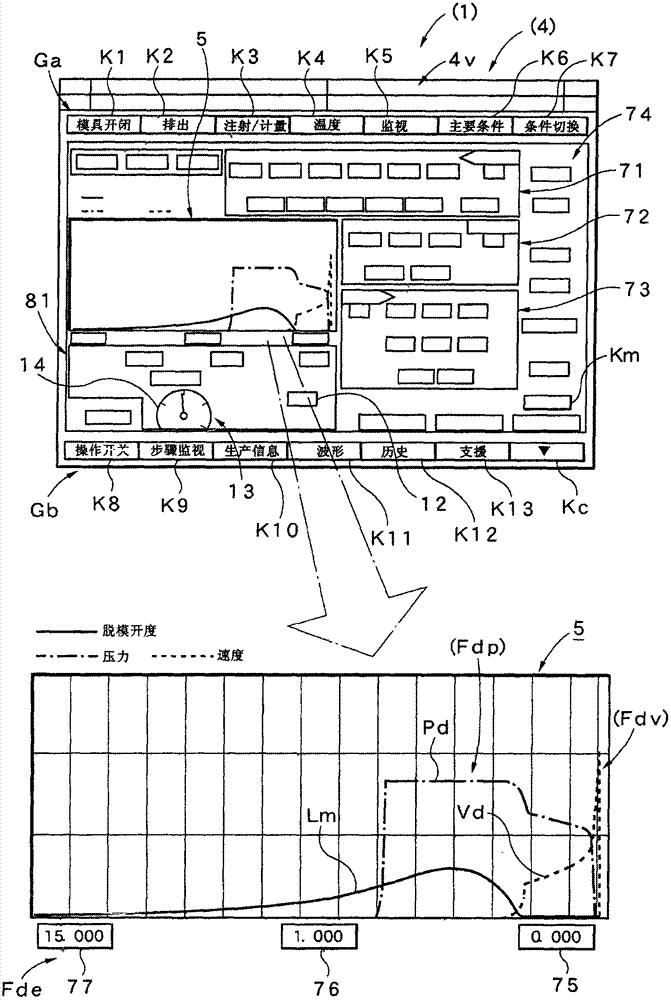

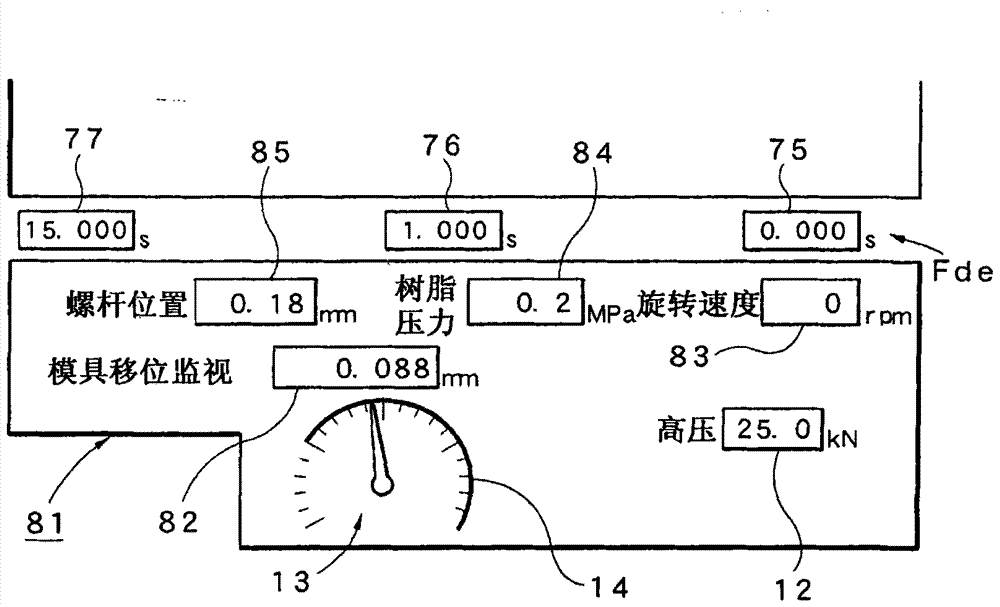

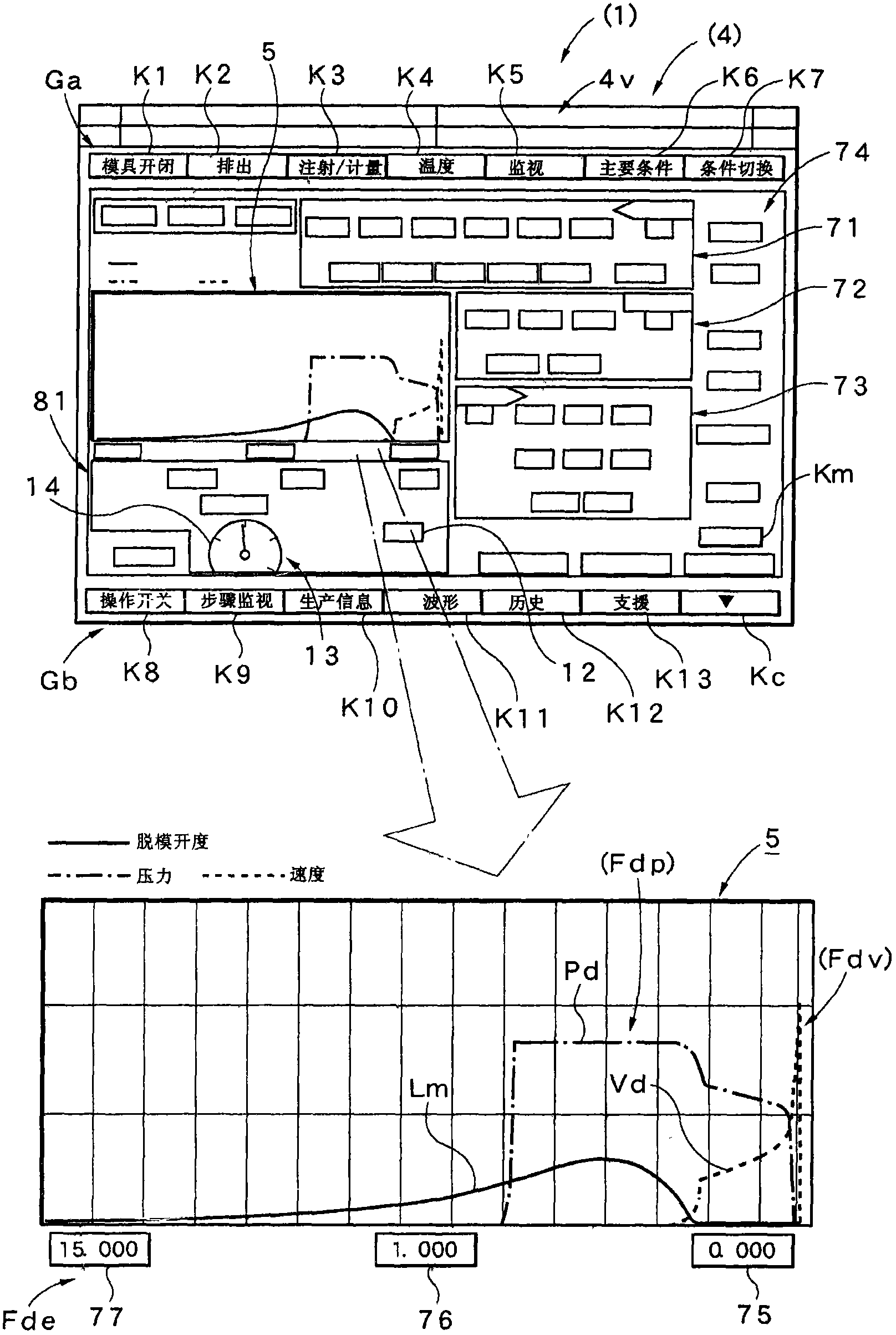

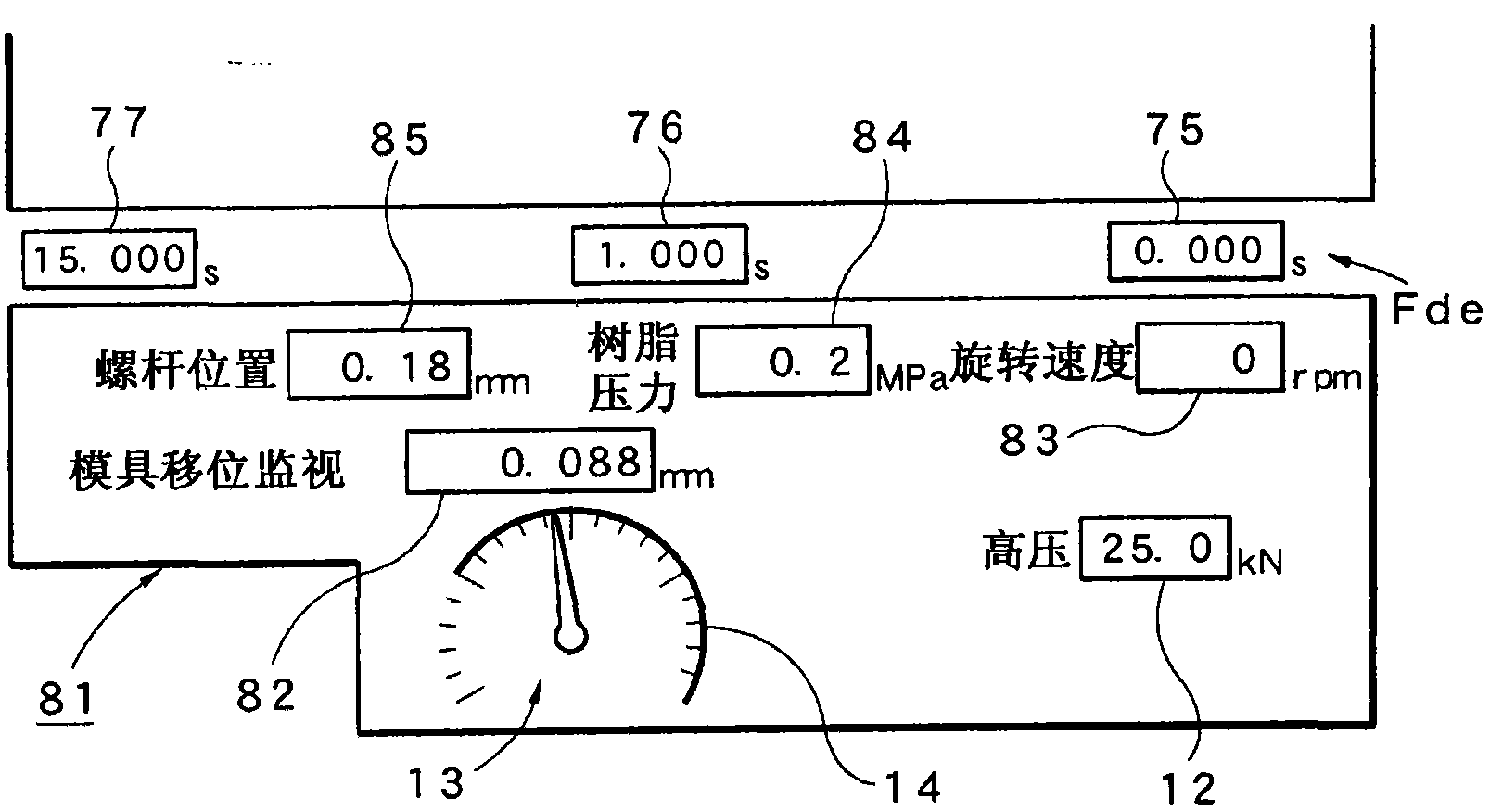

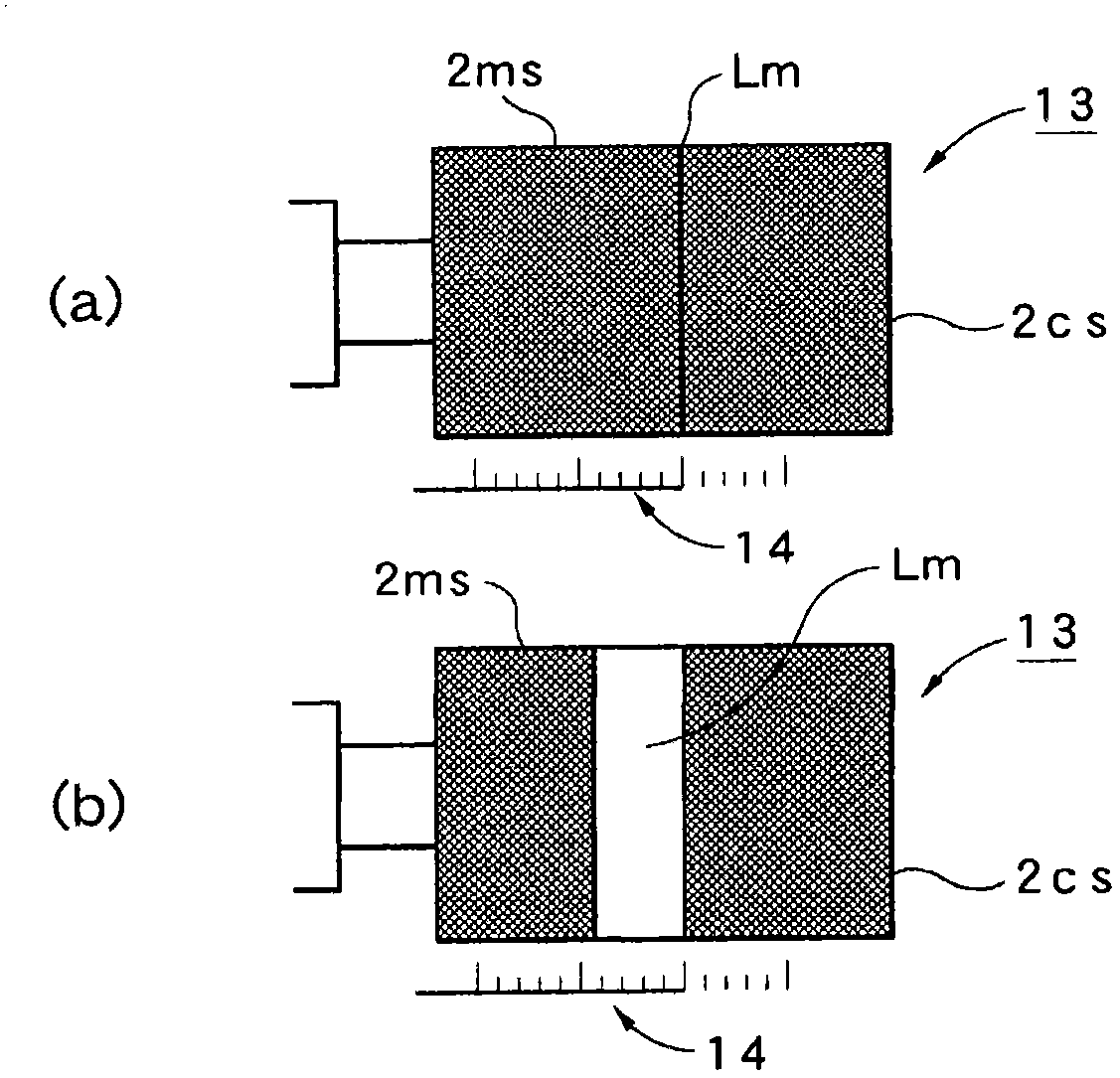

Waveform monitor apparatus of injection molding machine

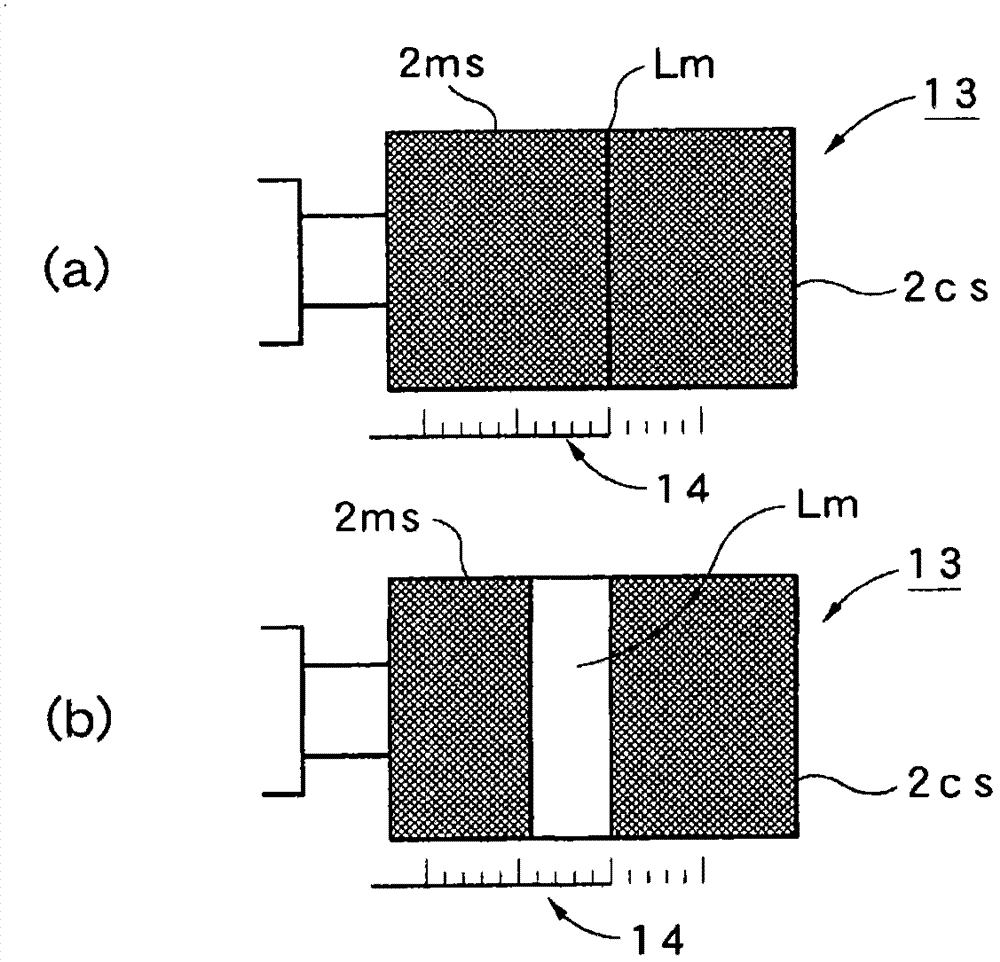

Waveform monitor apparatus of injection molding machine. When a waveform monitor apparatus (1) of an injection molding machine (M) for monitoring an operation waveform at least during molding is configured by mounting the waveform monitor apparatus (1) on the injection molding machine (M) for performing molding according to a specific molding system, a parting opening detecting means (Fp) for detecting change data of a parting opening (Lm) to a time during molding, and an operation waveform displaying means (Fd) for displaying at least change data from a resin filling start (ts) is into a mold (2) to a cooling time termination (te) to of the mold (2), detected by the parting opening detecting means (Fp), on a waveform displaying portion (5) of a screen (4v) on a display (4) attached to a molding machine controller (3) are provided.

Owner:NISSEI PLASTIC IND CO LTD

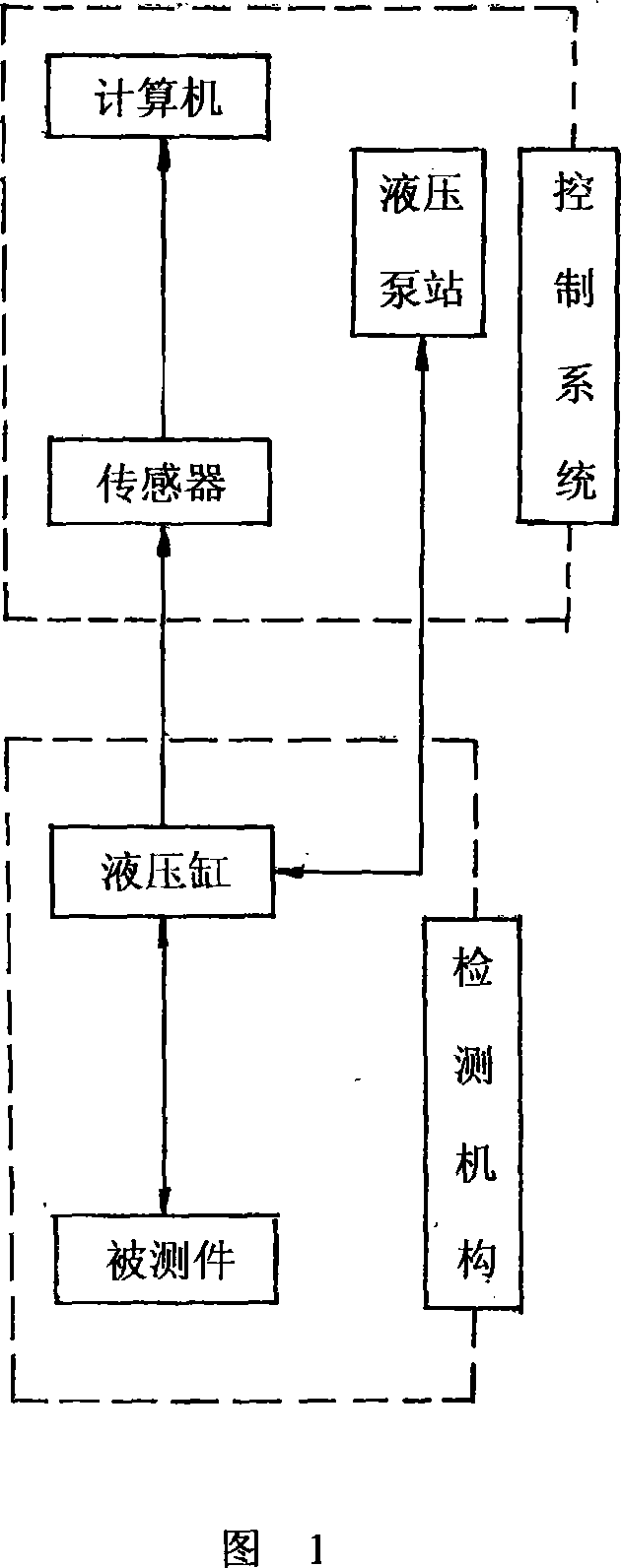

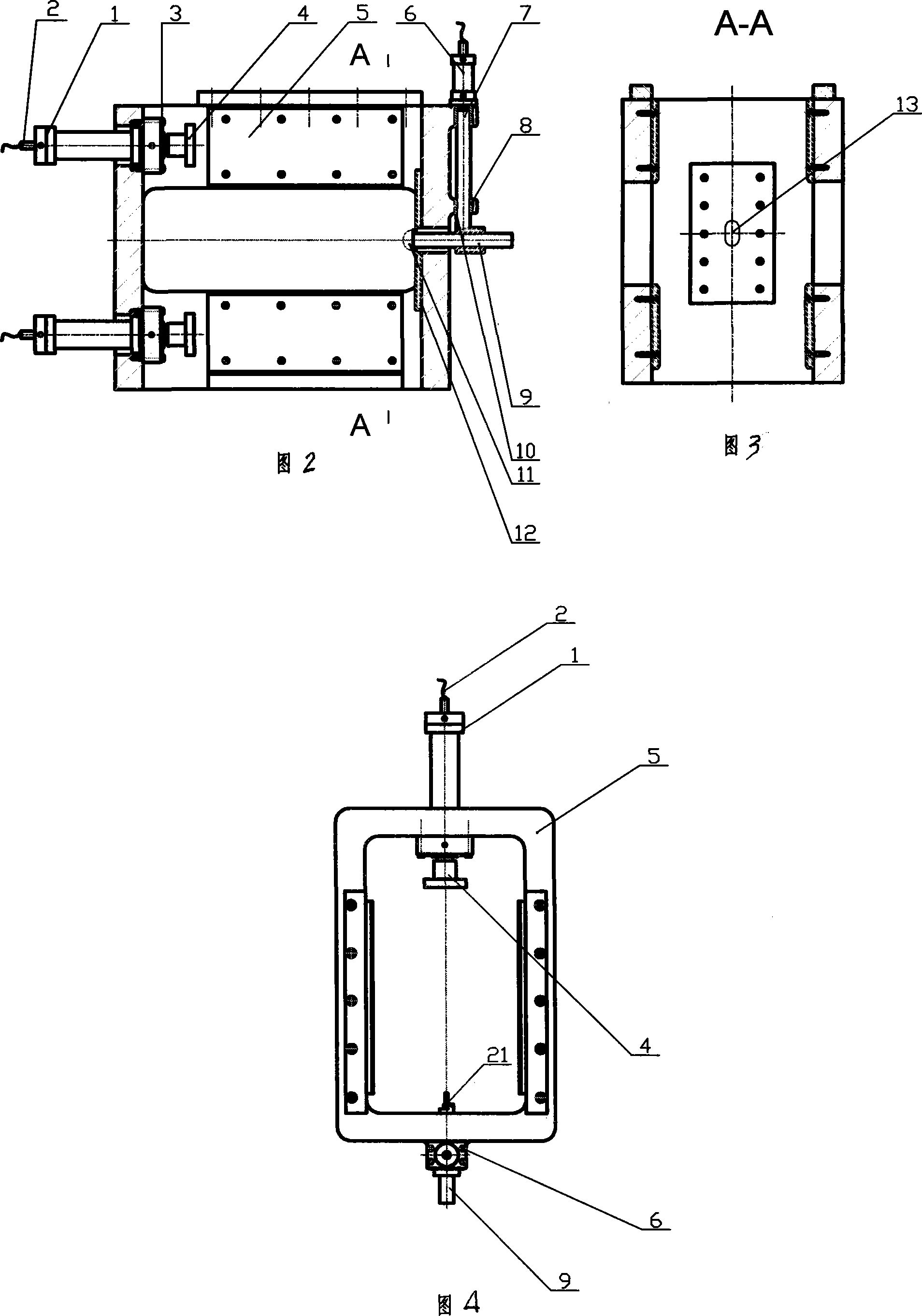

Error measuring device of weldless pipe continuous rolling mill roller and detecting method thereof

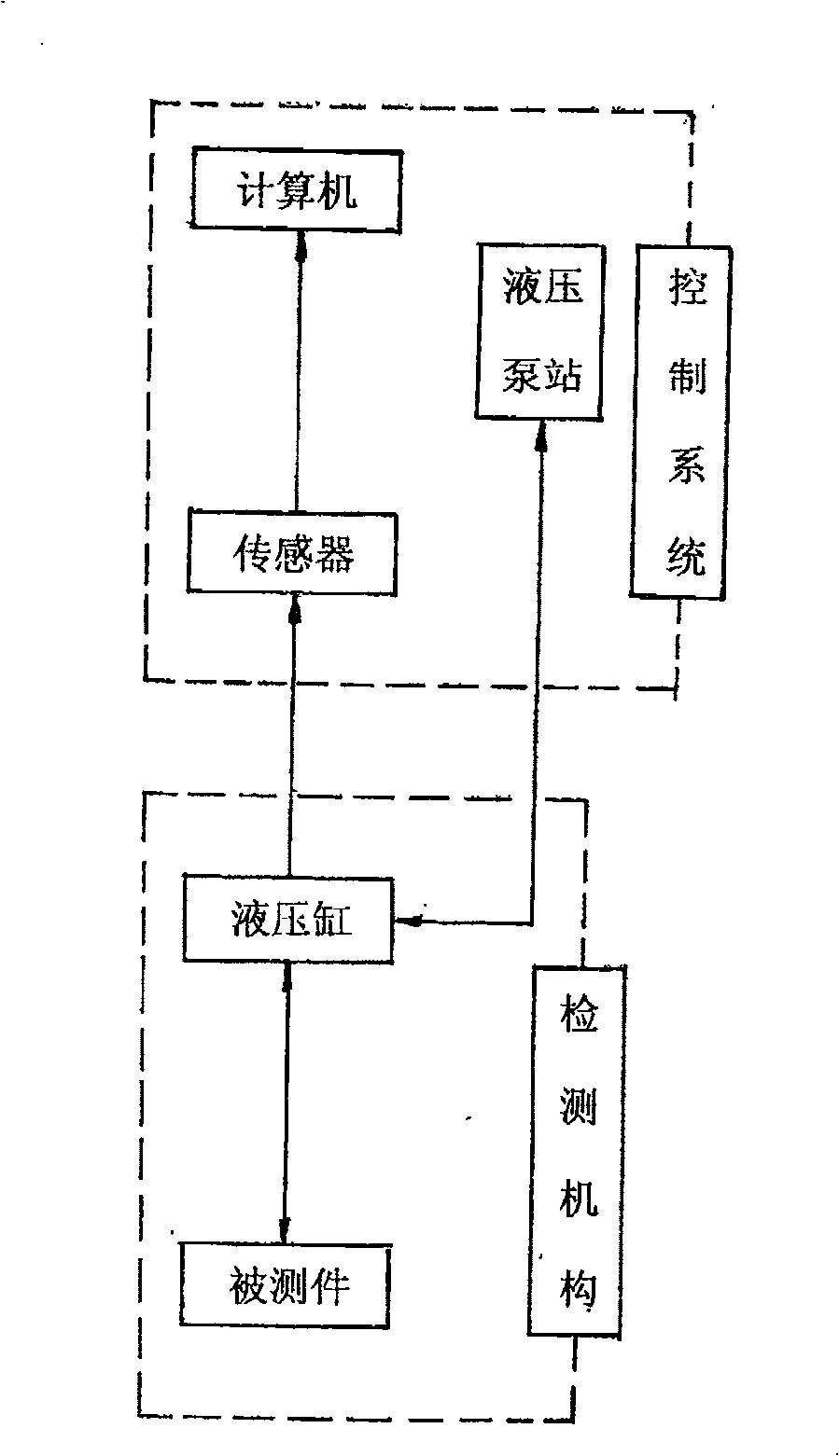

InactiveCN101108397AEliminate gapsHigh precisionMeasuring devicesUsing fluid meansHydraulic cylinderTest frame

The invention relates to a seamless pipe tandem rolling machine rolling roller bias test device and the test method, a lifting hydraulic pressure cylinder and an impelling hydraulic pressure cylinder of the displacement sensor are fixed on the test frame, which are connected with a computer by cable and are communicated with a hydraulic pressure pump. A rolling roller and a bearing box are arranged on the test frame, the impelling hydraulic pressure cylinder presses the rolling roller loop against to a return board; the displacement sensor inputs the tested numerical value to the computer to converse and sort out, then get the practical bias value of the top nest work surface of the bearing box from the centre line of the rolling roller. The lifting hydraulic pressure cylinder makes the pore-typed sample stick to the roller roll pore, the displacement sensor inputs the tested numerical value to the computer to sort out, then achieve the practical bias value of the cushion block working surface of the bearing box from the centre of the rolling roller pore. The invention overcomes the gap among the machines, excludes artificial error and removes safety danger, which makes the measurement accuracy is increased into 2 to 3 times than the artificial measurement value, the test time can be shorten for 5 hours.

Owner:ANGANG STEEL CO LTD

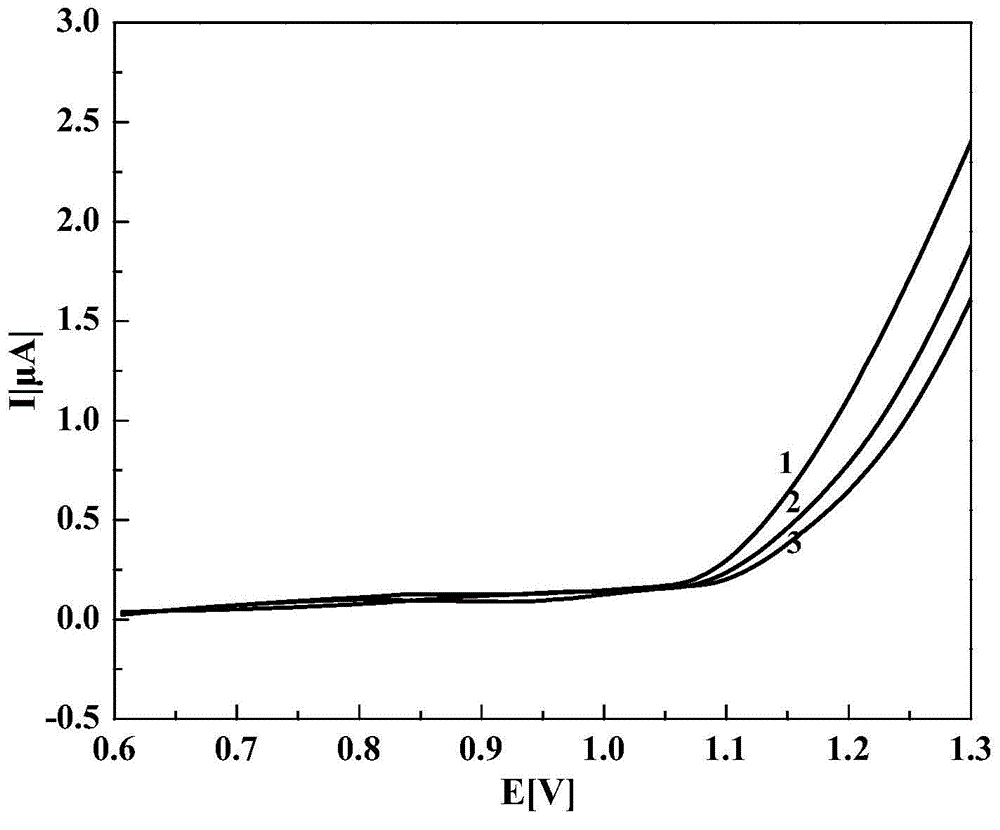

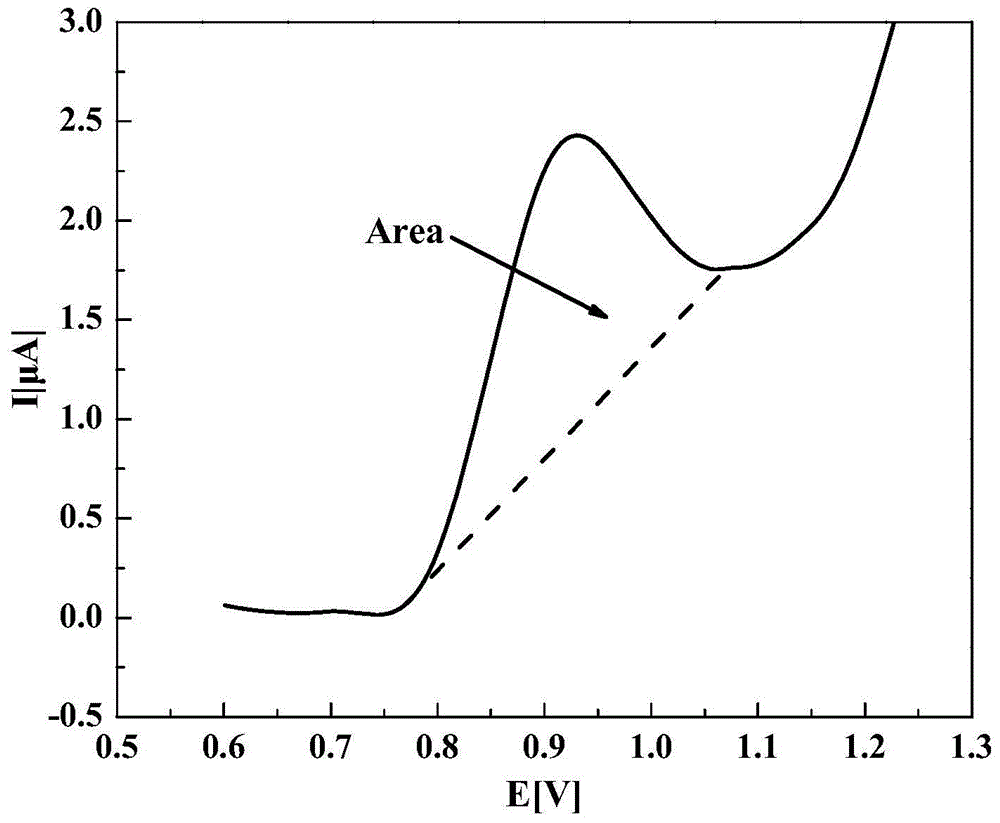

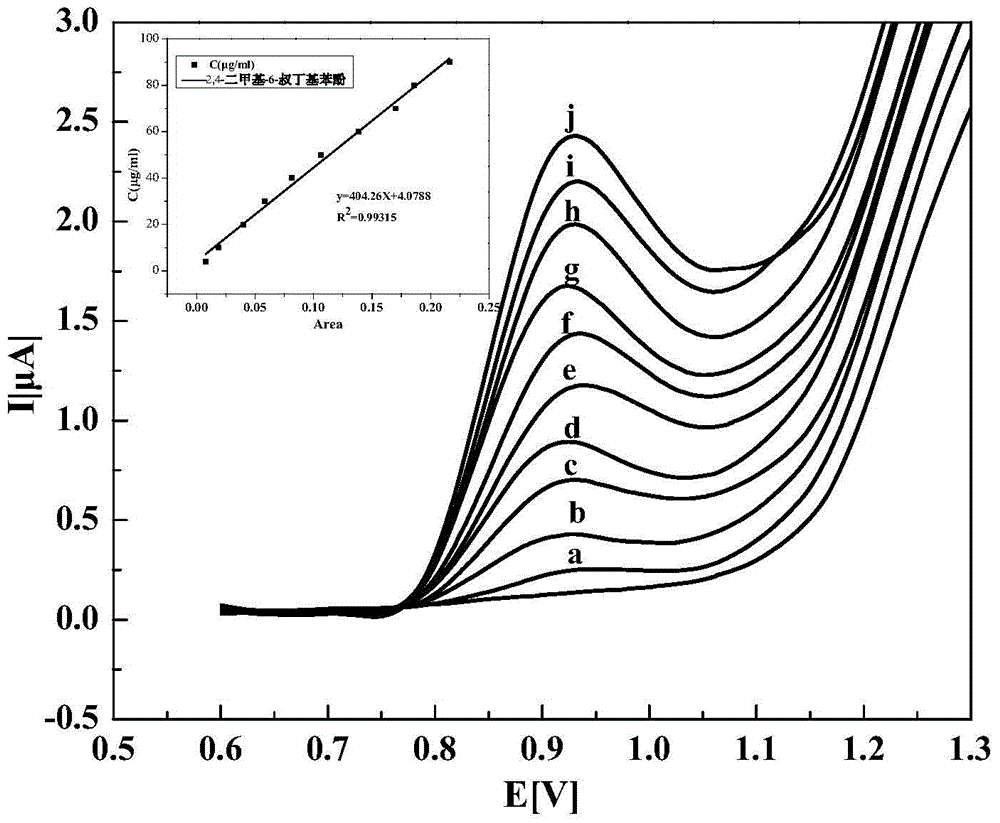

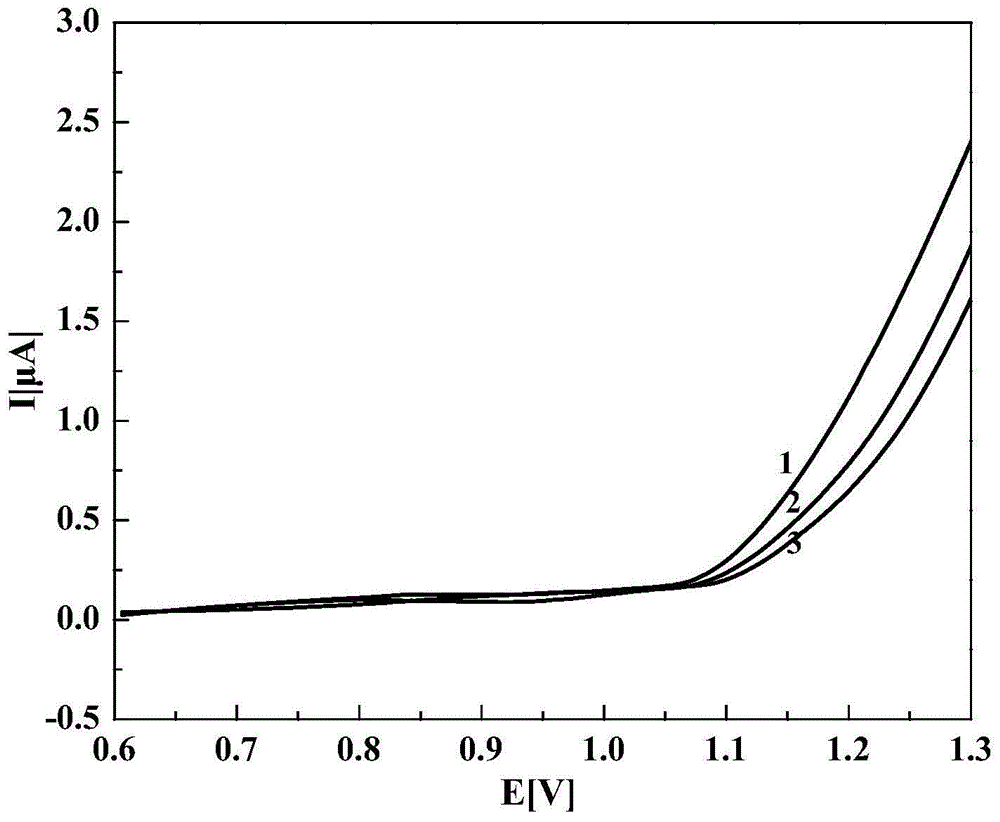

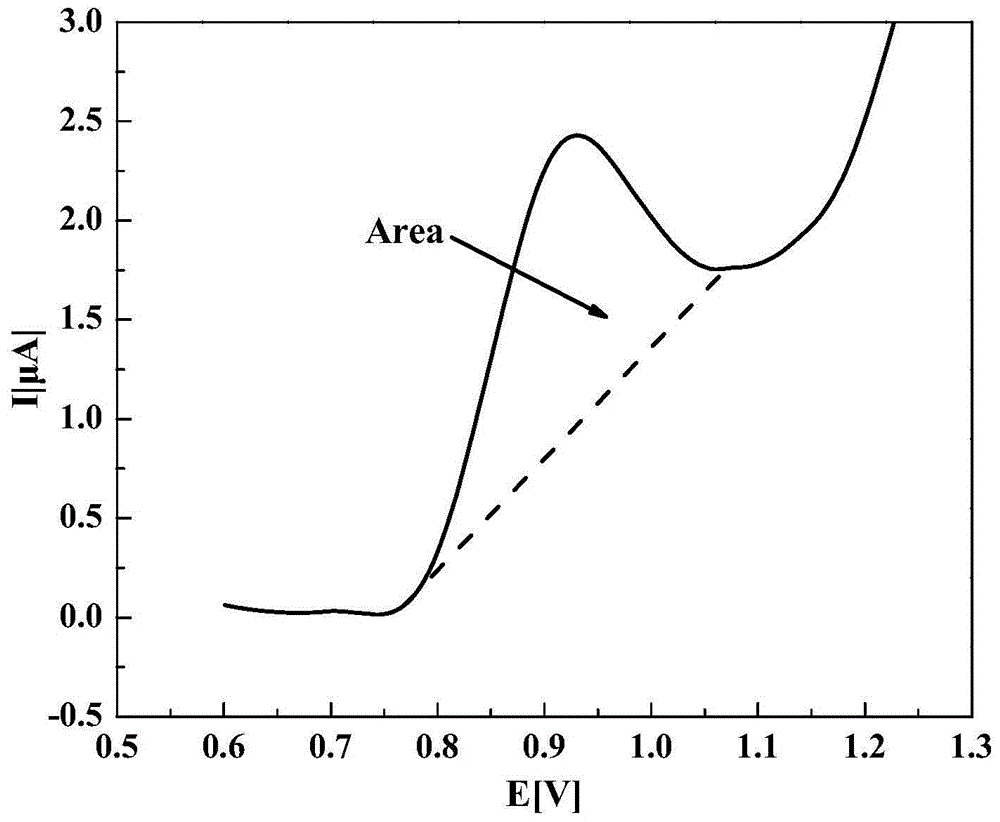

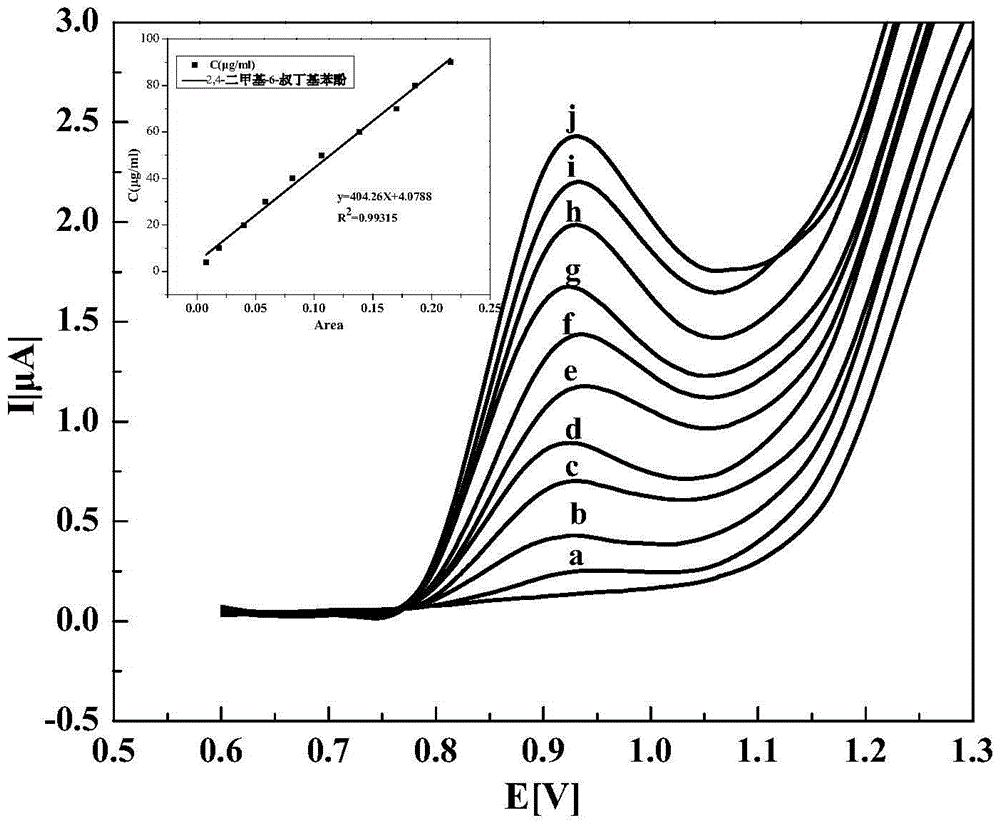

Method for measuring antioxidant content in lubricating oil by use of linear sweep voltammetry

ActiveCN104597101AImprove accuracyImprove applicabilityMaterial electrochemical variablesAntioxidantPeak area

The invention provides a method for measuring the antioxidant content in a lubricating oil by use of linear sweep voltammetry, and belongs to the technical field of electrochemical detection. The method comprises the following steps: adding an ethanol solution of which the antioxidant concentration is known to an electrolyte, measuring by use of the linear sweep voltammetry to obtain the characteristic voltage-current curve of the electrolyte, calculating the characteristic peak area of the curve, establishing a working curve of the antioxidant concentration and the characteristic peak area, extracting new lubricating oil with the known antioxidant content and lubricating oil with unknown antioxidant content by using ethanol, adding the supernatant liquid to the electrolyte, measuring by use of the linear sweep voltammetry to obtain the characteristic voltage-current curve of the electrolyte, calculating the characteristic peak area of the curve, and substituting the characteristic peak area of the known antioxidant into the working curve to obtain the correction coefficient of the lubricating oil of the antioxidant to obtain the unknown antioxidant content. The method is simple, convenient and quick to operate, and high in sensitivity, and can be widely applied to the measurement of the antioxidant content in synthetic oil or mineral oil lubricating oil and the rapid evaluation of the oxidative stability of the lubricating oil.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

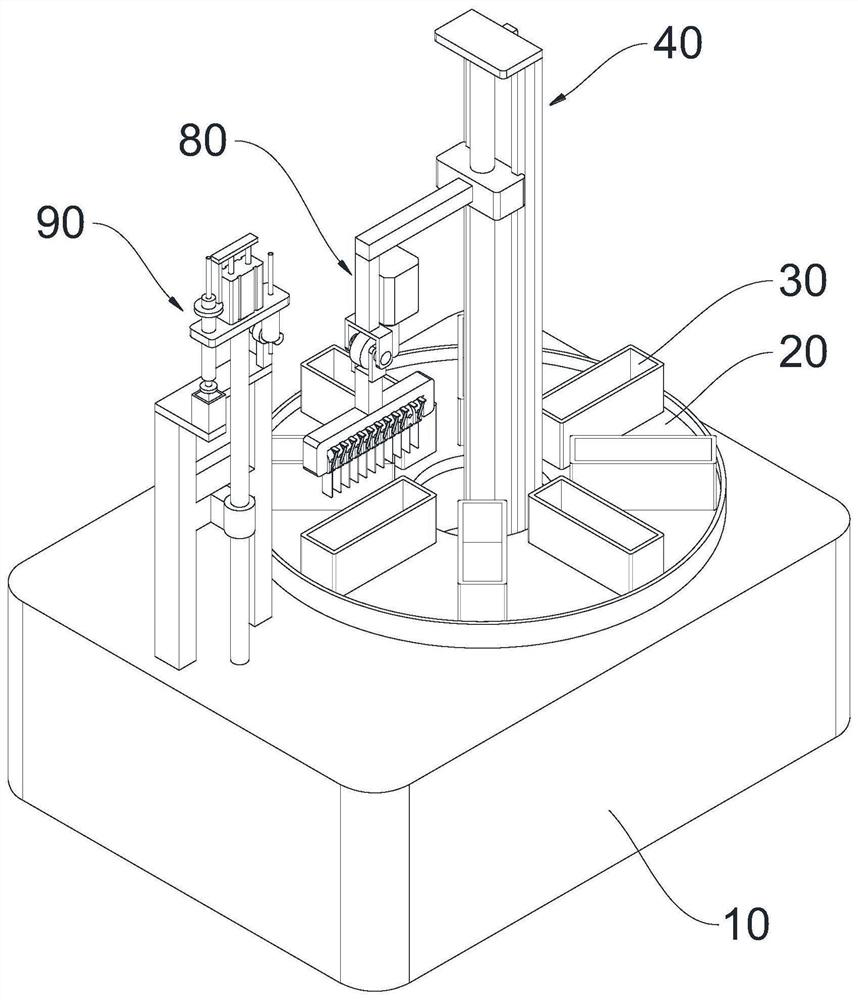

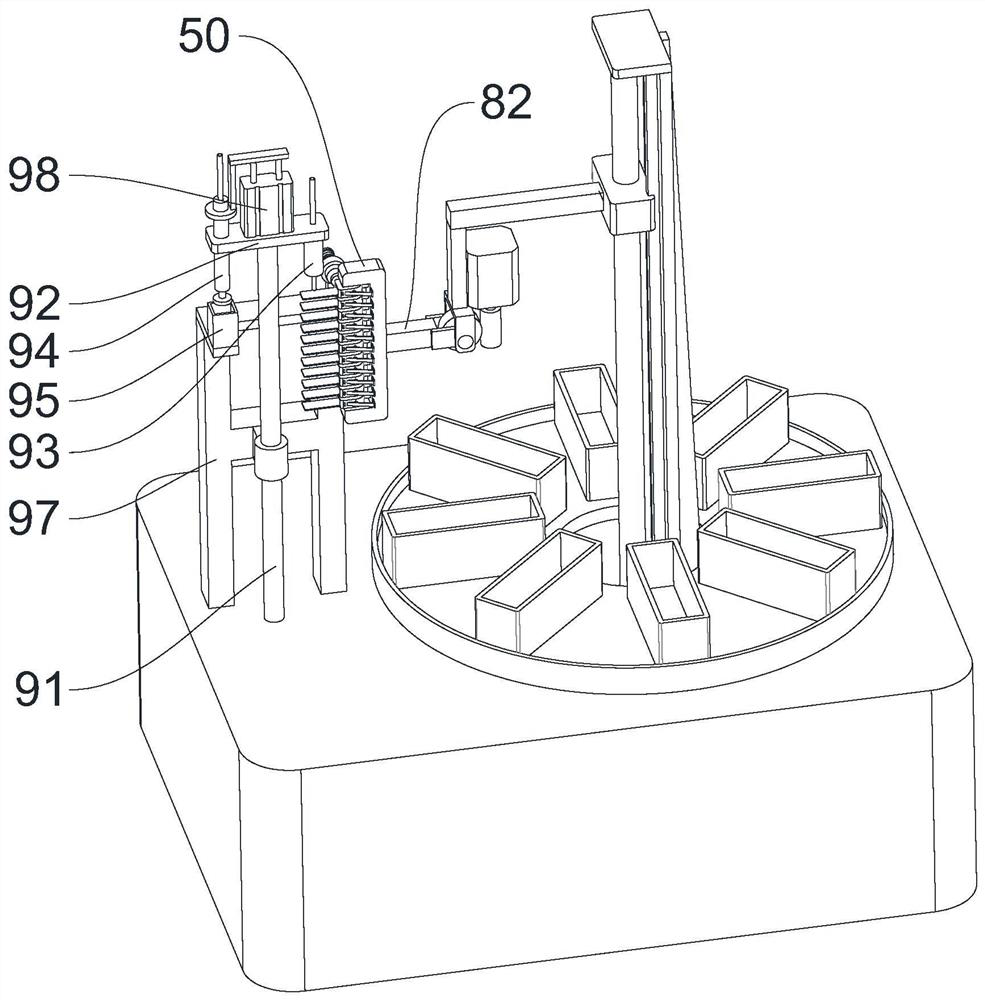

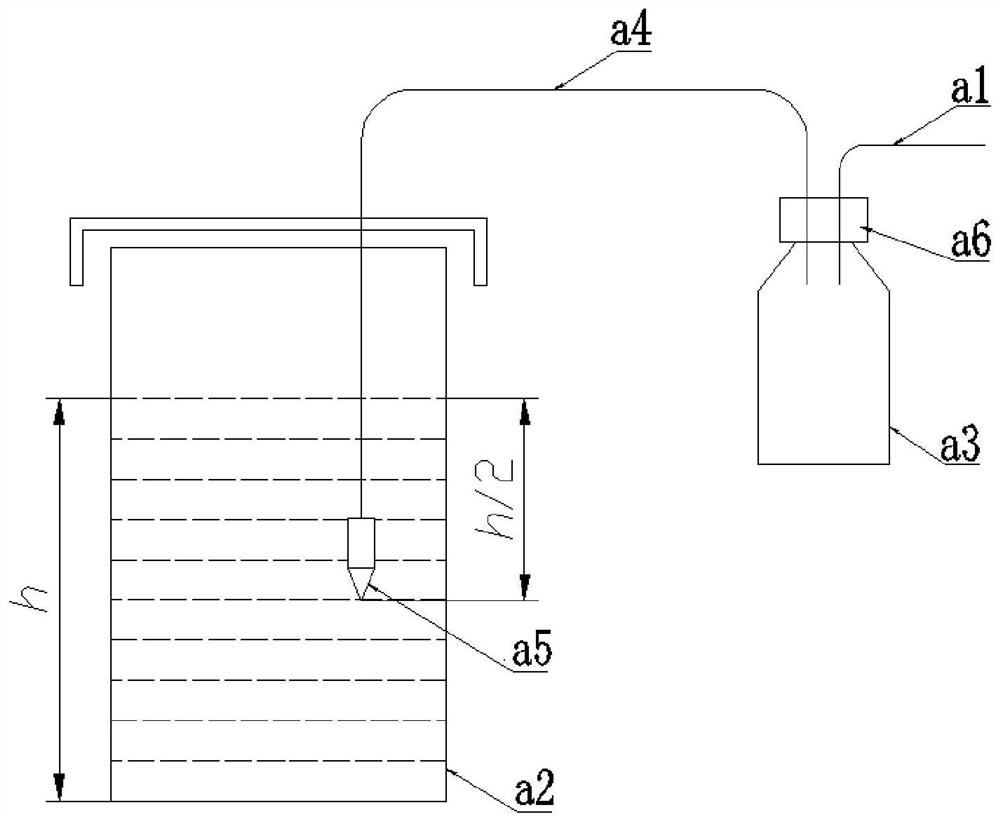

Cell staining device

ActiveCN113959815ARealize automatic dyeingEliminate error factorsPreparing sample for investigationGlass productionStainingEngineering

The invention provides a cell staining device. The cell staining device comprises a base, an annular turntable, a plurality of liquid storage boxes, a lifting mechanism, a slide holder, a chuck, a limiting unit, a turnover mechanism, a sealing mechanism and an impact unit. According to the device, automatic dyeing and automatic sheet sealing can be realized, error factors of manual operation are removed, the defects of unstable quality and poor effect of manual dyeing and sheet sealing are overcome, and the dyeing and sheet sealing quality is improved.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Test method for researching concrete crack chemical excitation healing

InactiveCN110220778AAvoid crackingEliminate error factorsAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationMaterials preparationSelf-healing

The invention discloses a test method for researching concrete crack chemical excitation healing. The test method comprises the steps of: material preparation; test block preparation; mechanics performance testing; ultrasonic wave velocity testing; and experiment conclusion analysis. Cracks are prefabricated for the magnesium oxide concrete test blocks with different mixing amounts, the maintenance test is performed in sodium sulfate solutions with different concentrations, the rebound wave velocities of the test blocks with the cracks are measured by utilizing an ultrasonic comprehensive rebound method, the wave velocities and the compressive strength change of the test blocks at different maintenance ages are contrastively analyzed, the chemical excitation effect of the magnesium oxide and the sodium sulfate on the self-healing performance of the concrete cracks is researched, and the obtained experimental conclusion provides theoretical reference for the application and developmentof the chemical excitation healing of the concrete cracks in engineering.

Owner:NANHUA UNIV

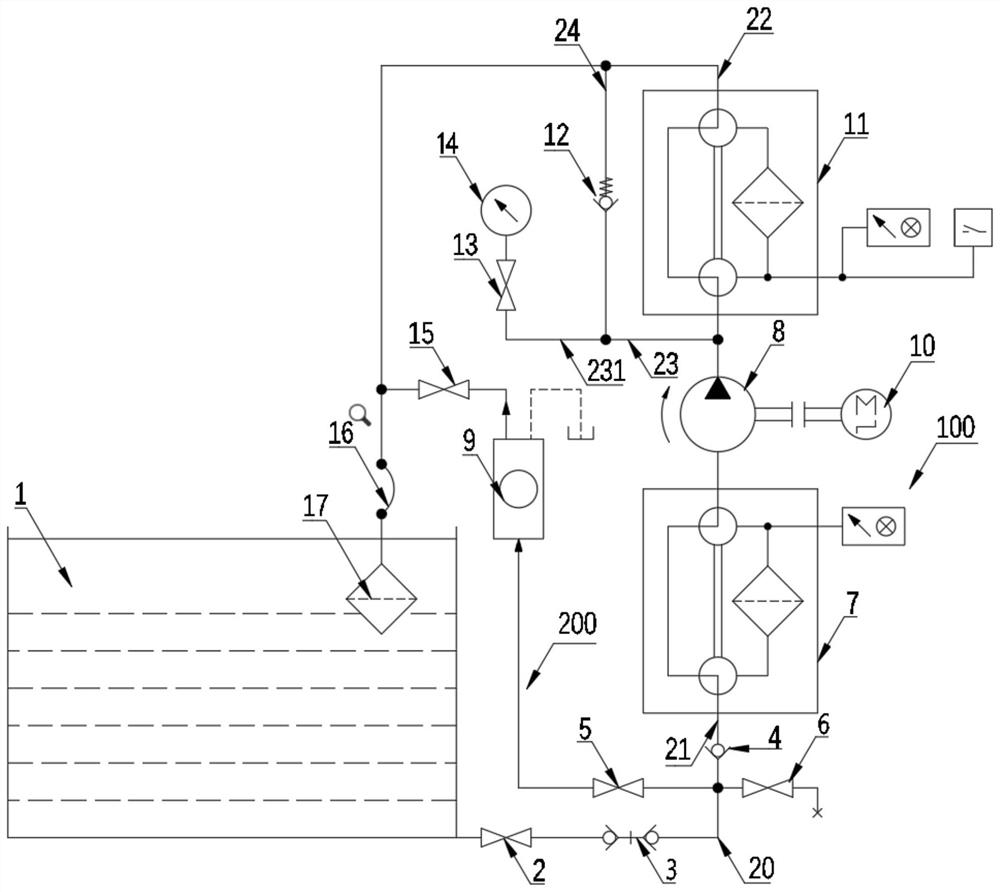

Device and method for monitoring (detecting) pollution degree of hydraulic oil particles sampled from drain valve

PendingCN111734715AWell mixedGuaranteed accuracyFluid-pressure actuator testingWithdrawing sample devicesHydraulic pumpPollution

The invention discloses a device and method for monitoring (detecting) the pollution degree of hydraulic oil particles sampled from a drain valve, and belongs to the technical field of hydraulic oil monitoring (detecting). The device comprises a circulating circuit and a monitoring (detecting) circuit, wherein the circulating circuit comprises a one-way valve and a hydraulic pump for providing power, one end of the one-way valve is connected with one end of a first filter, the other end of the one-way valve is connected with an oil suction port of the hydraulic pump, reverse installation needsto be avoided, and an oil outlet of the hydraulic pump is connected with an oil injection filter in an oil tank through a third pipefitting; and the monitoring (detecting) circuit comprises a pollution degree monitoring (detecting) instrument, and the pollution degree monitoring (detecting) instrument is connected in parallel on the circulating circuit. The circulating circuit is arranged, thus flowing of hydraulic oil in a pipeline before the one-way valve can be in a fully turbulent state, pollutants deposited at the bottom of the oil tank or the bottom of the oil tank near the drain valvecan be mixed evenly, and a particle pollution degree liquid sample representing the oil tank and even the whole hydraulic system can be obtained at the drain valve.

Owner:苏州美福瑞新材料科技有限公司

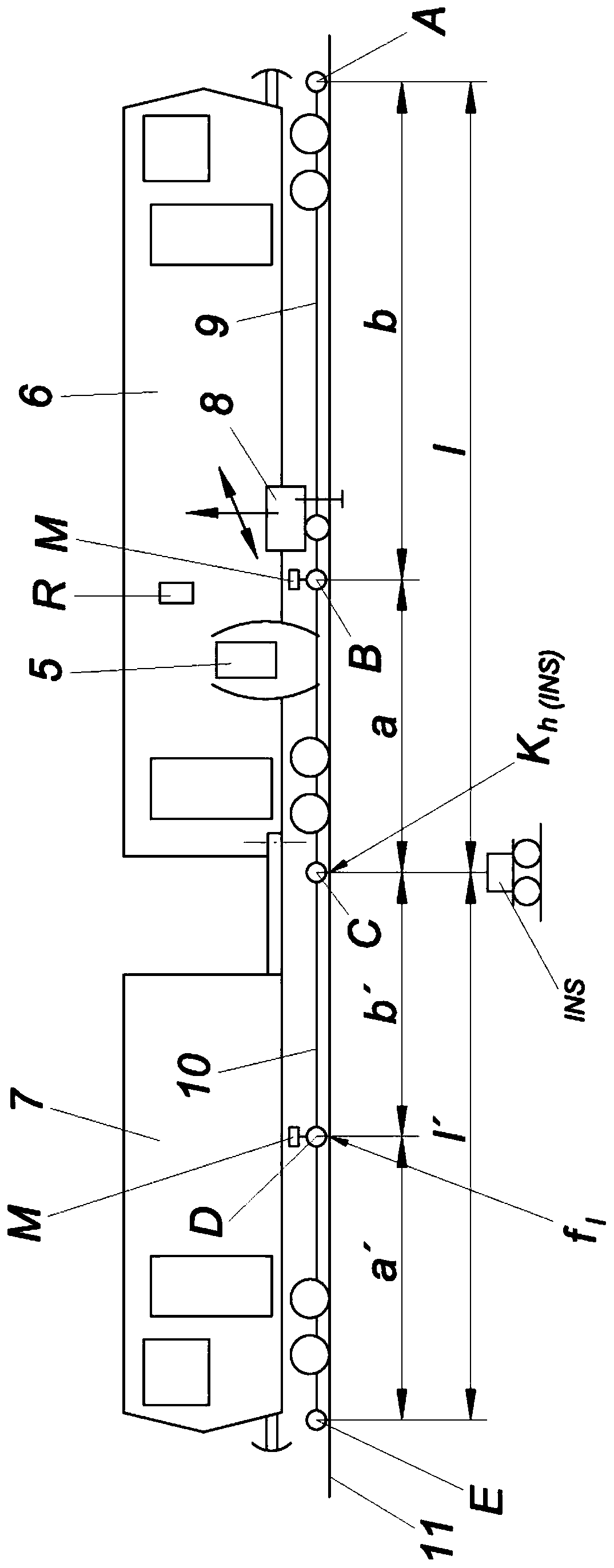

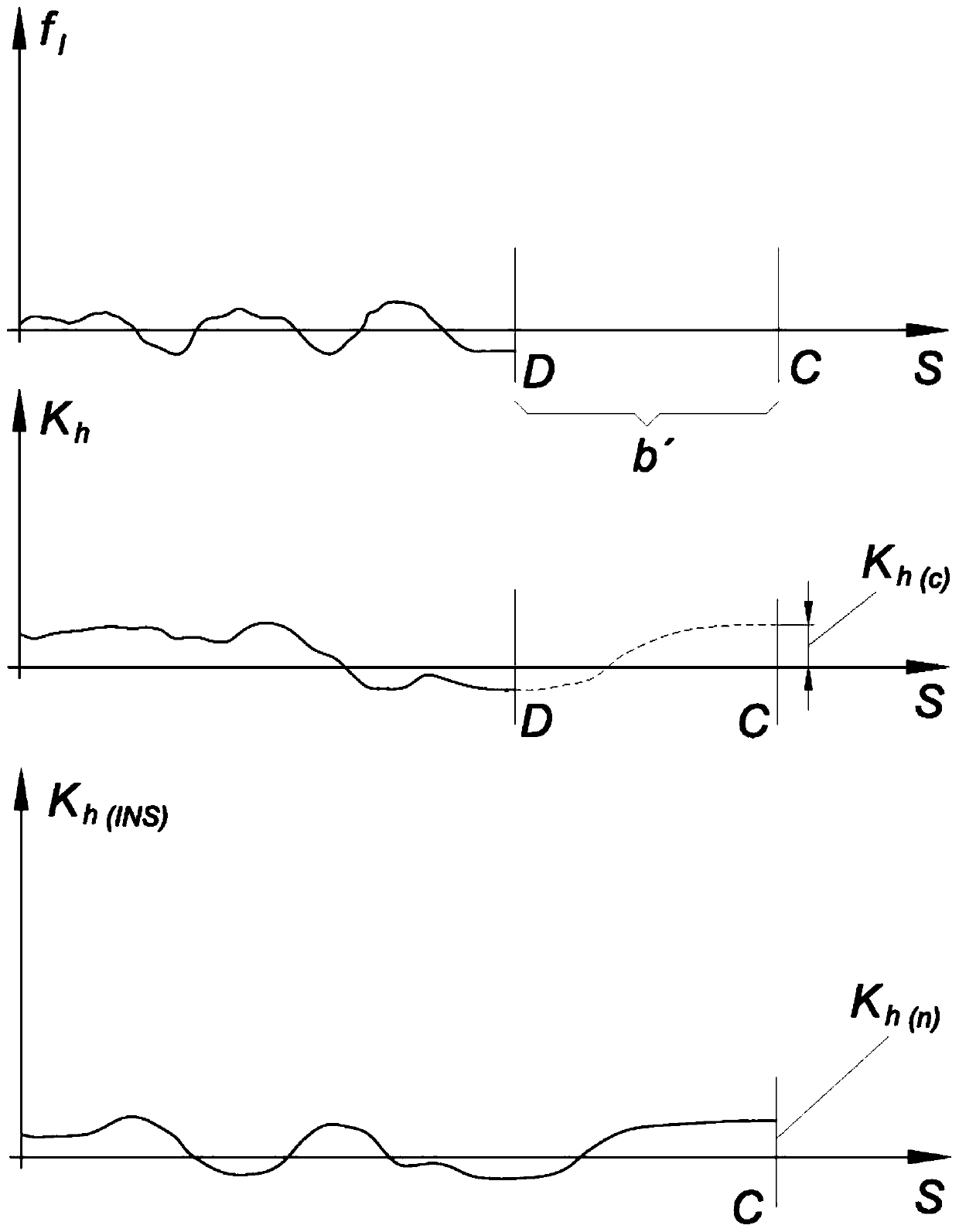

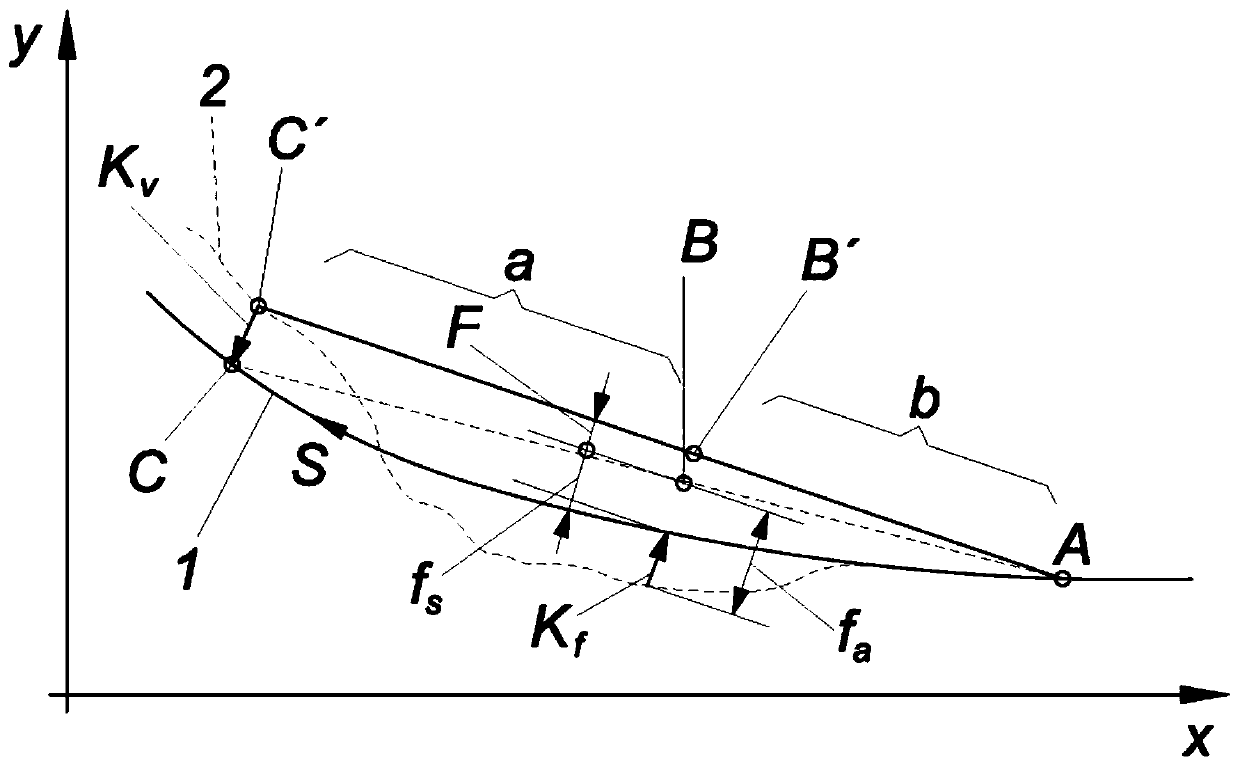

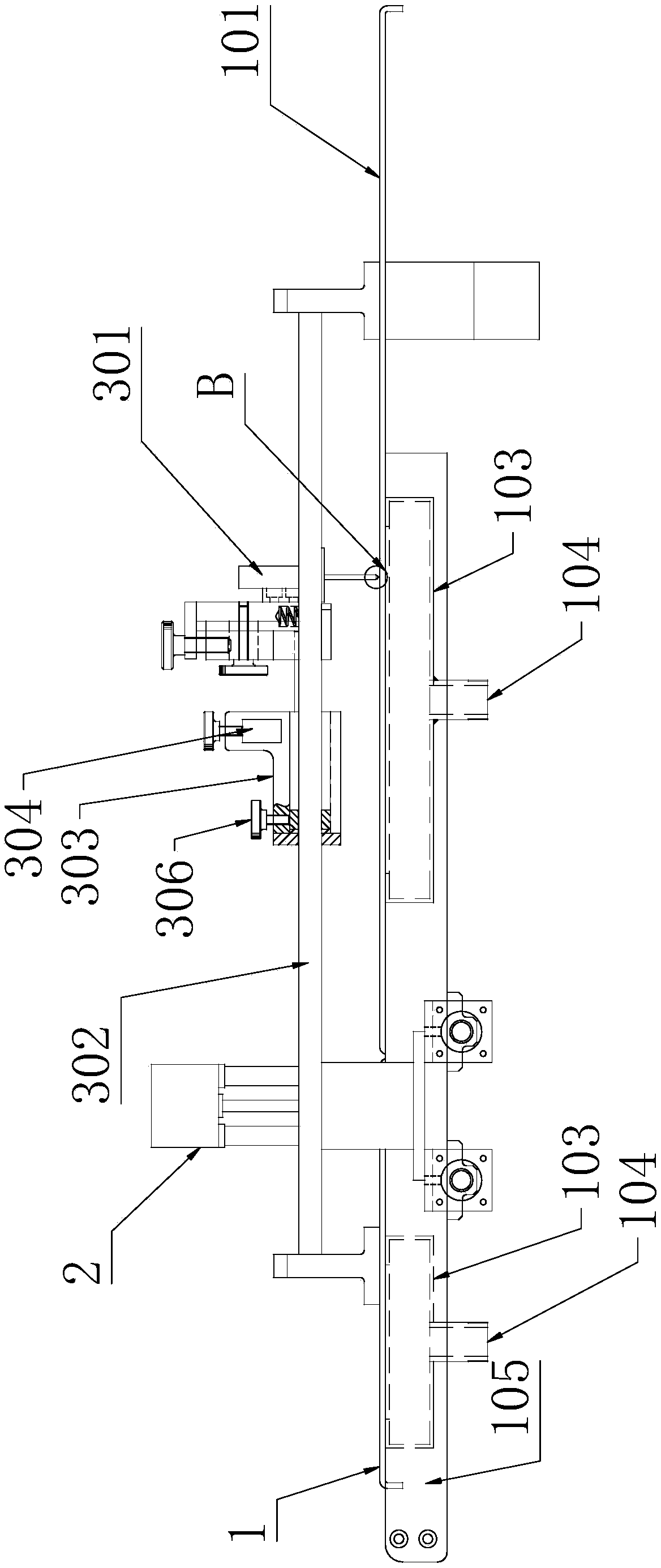

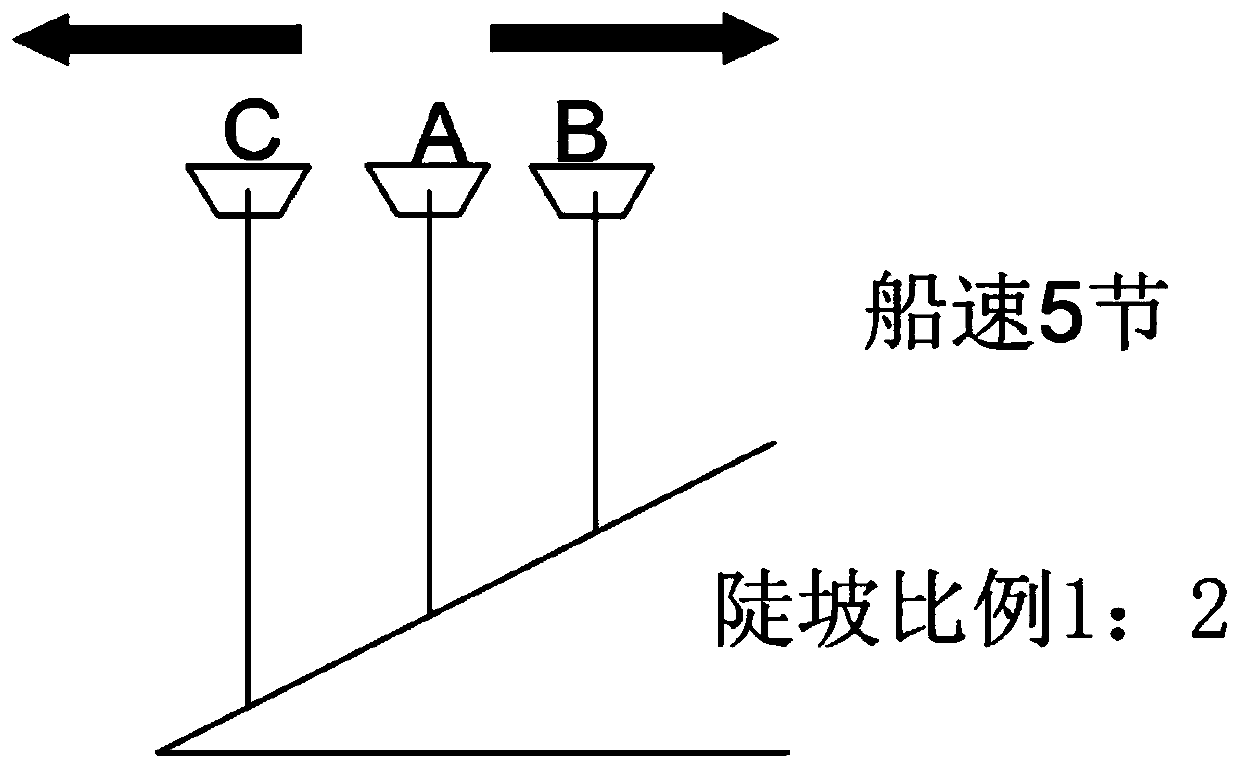

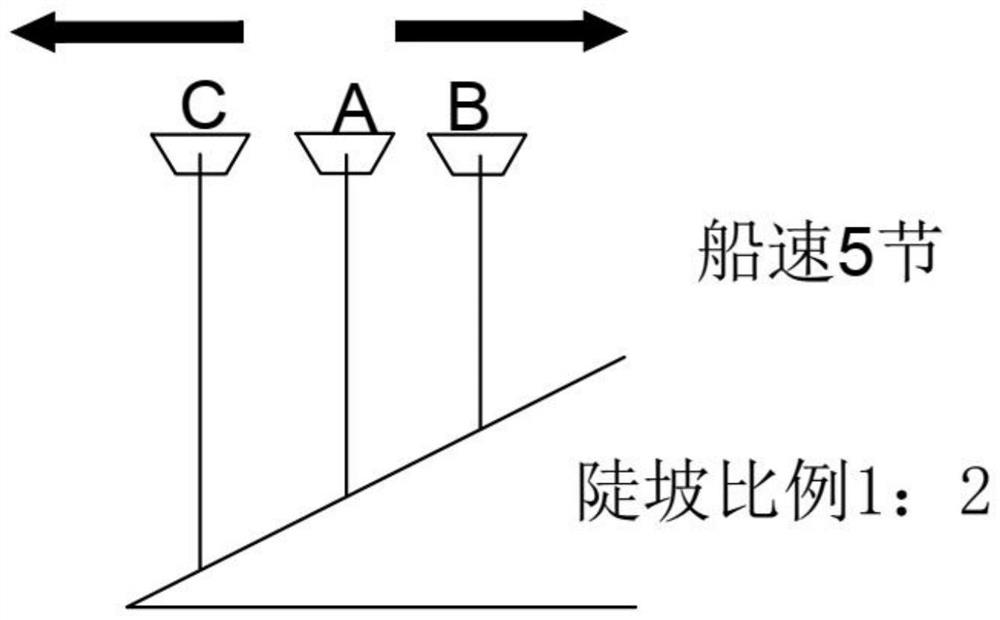

Method for track position improvement by means of a track-movable track-tamping machine

InactiveCN111566286AEasy to correctReduce correctionBallastwayMechanical clearance measurementsTrackwayControl engineering

A method for track position improvement by means of a track-movable track-tamping machine (6) with a three-point working measurement system, which has three measurement carriages (A, B, C), a cord (9)stretched therebetween, a tamping unit (5), a lifting / straightening assembly (8) for tracks and an odometer particularly. The position of the track after the correction work of the track-tamping machine (6) is recorded by the measurement system, wherein a computer (R) calculates the difference between a predetermined desired track position (1) and an actual position recorded by the measurement system, that is to say a residual error (Kh), and the position of the rear cord end at the rear measurement carriage (C) of the track-tamping machine (6) of the three-point working measurement system iscontinuously corrected in such a way that the rear cord end at the measurement carriage (C) is guided on the desired track position (1).

Owner:HP3 REAL GMBH

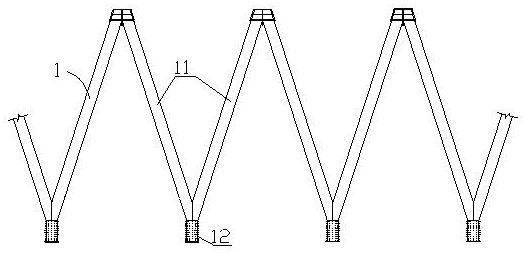

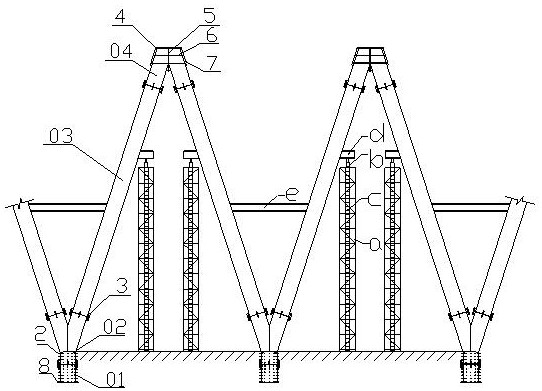

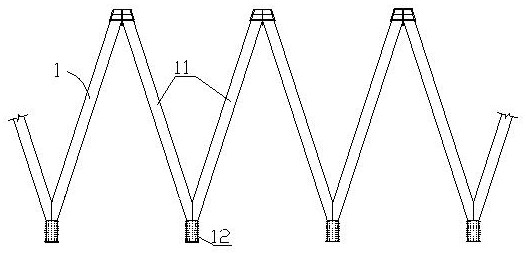

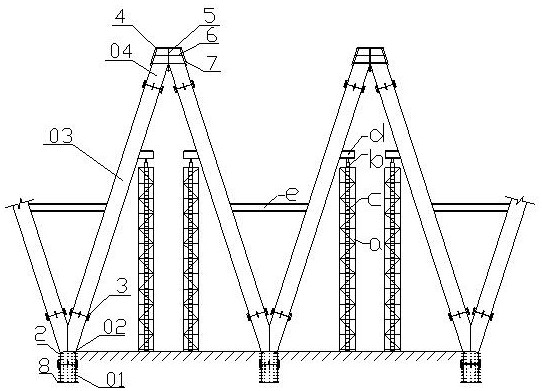

Construction method of large-diameter thick-wall continuous Y-shaped steel pipe column

ActiveCN112554577AGuaranteed positioningGuaranteed fixed effectStrutsBuilding material handlingWhole bodyThick wall

The invention discloses a construction method of a large-diameter thick-wall continuous Y-shaped steel pipe column. The method comprises the following steps: establishing a BIM model of the continuousY-shaped steel pipe column, and decomposing the continuous Y-shaped steel pipe column into n embedded pipe sections, n Y-shaped column sections, 2n inclined column sections and n-1 inverted V-shapedcolumn sections from bottom to top; blanking to manufacture each section; pre-assembling the whole body; performing quality inspection on the pre-assembly; coating, numbering and packaging all the sections, and transporting the sections to an installation site; assembling each embedded pipe section and the corresponding Y-shaped column section into a lower part on site, and assembling the two inclined column sections and the corresponding inverted V-shaped column sections into an upper part; hoisting all lower parts; hoisting an upper part; then sequentially hoisting another upper part adjacent to the previous upper part to finish hoisting of all the upper parts; and performing welding. The construction method is high in machining quality and convenient to transport, the installation angleof the inclined column can be adjusted, the construction period is short, and the construction efficiency is high.

Owner:中冶建工集团重庆建筑工业有限公司

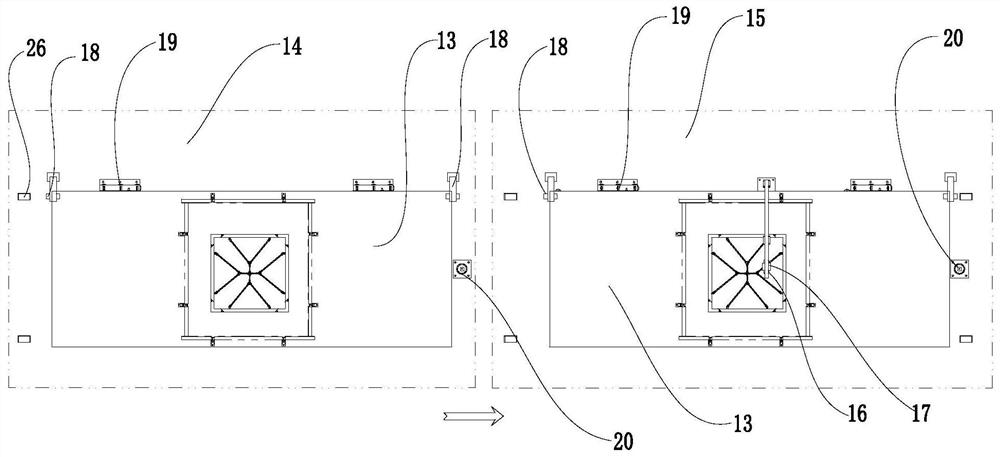

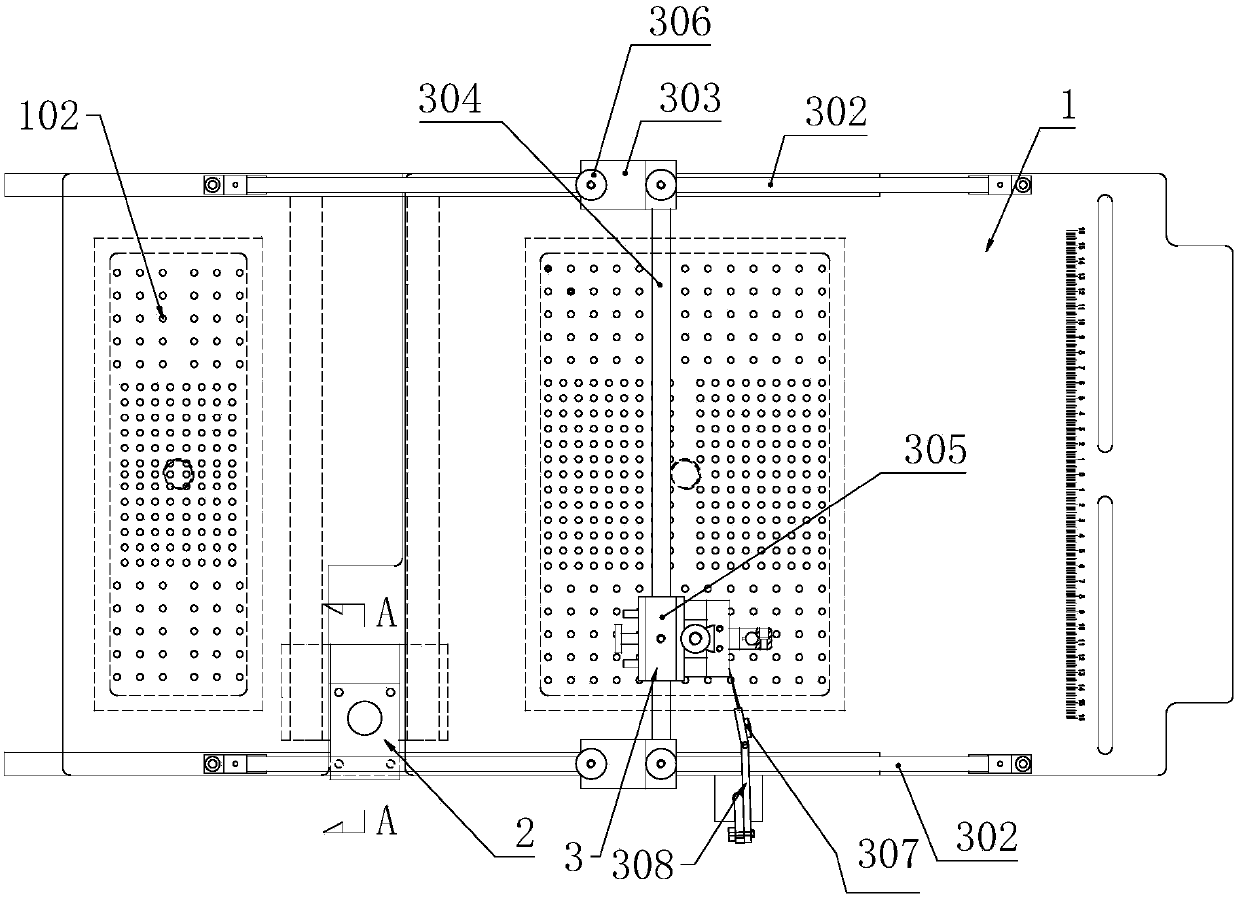

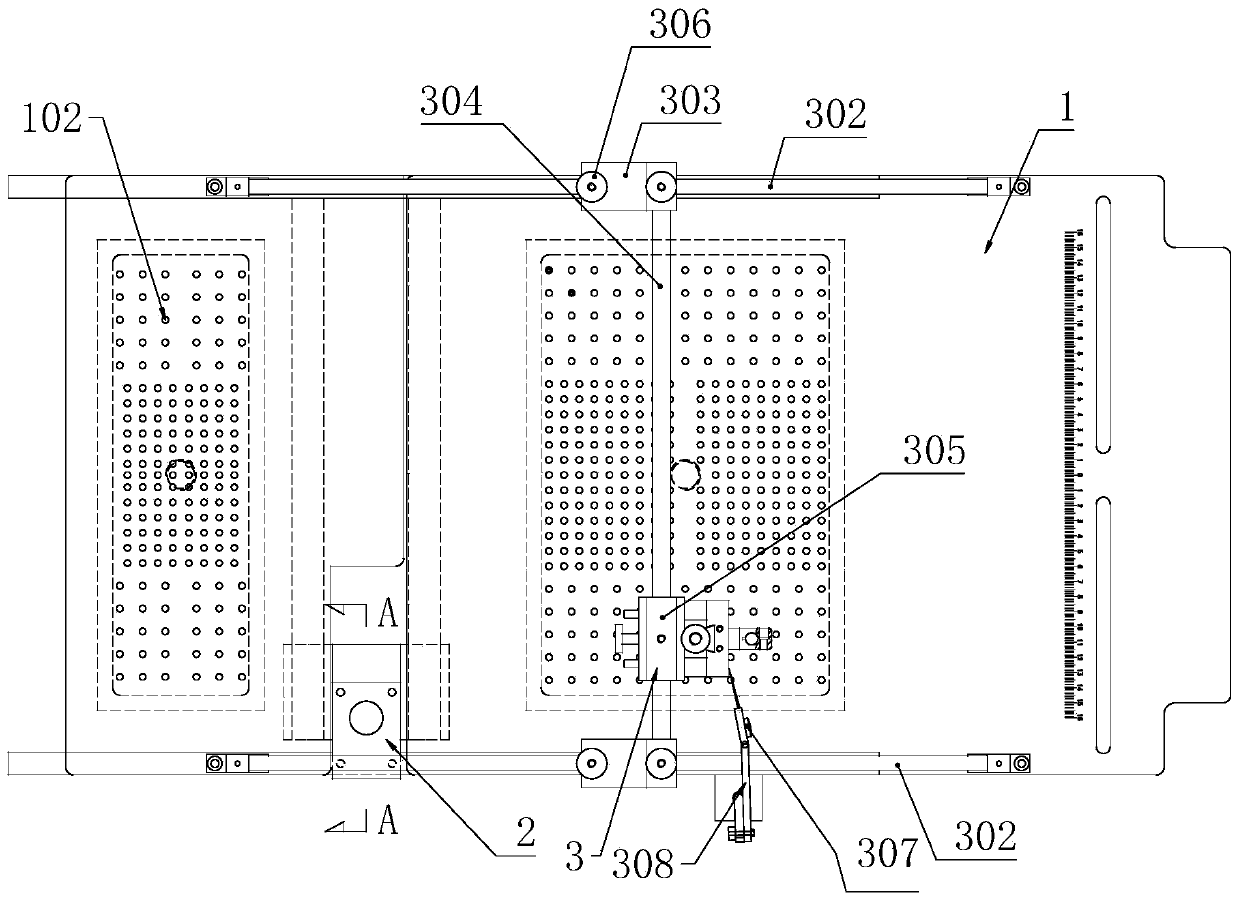

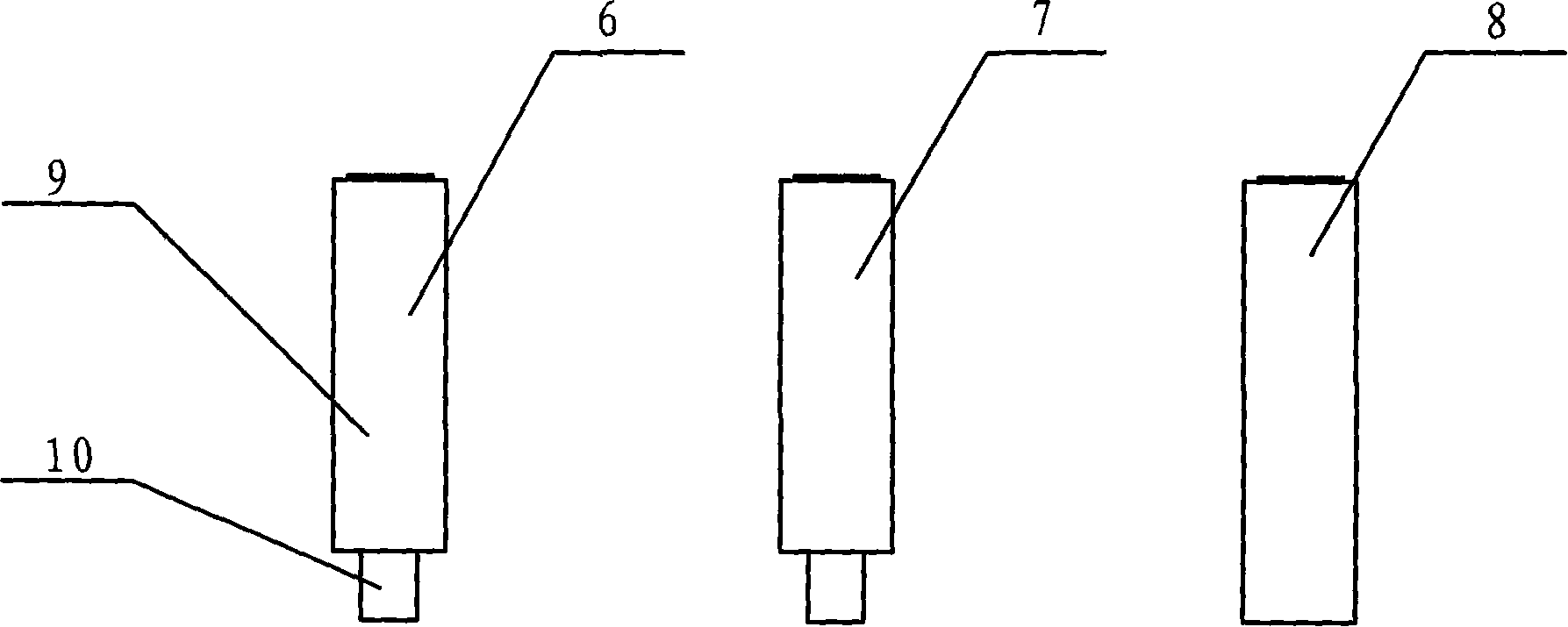

Positioning method for mold platen on preformed part production line

ActiveCN111775301APrevent deviationEliminate error factorsMoulding surfacesTelevision system detailsData controlControl engineering

The invention relates to a positioning method for a mold platen on a preformed part production line. The method includes the steps that (1) the position information of the mold platen at station A isobtained and sent to control processing modules; (2) the mold platen is moved to station B, and the position information of the mold platen at station B is obtained and sent to the control processingmodules; (3) relative offset data of the position of the mold platen at the station B relative to the position of the mold platen at the station A is calculated and obtained by the control processingmodules; and (4) the control processing modules control a rectifying mechanism mounted above the station B to move, the rectifying mechanism drives a projecting mechanism to move to a designated position, the projecting mechanism projects drawing information of the prefabricated part in the form of laser lines to the mold platen located at the station B, and the laser lines projected is corresponded to an operation position at the situation A. The positioning method for the mold platen on the preformed part production line can accordingly adjust and correct the position information of the moldplaten, and realize the high-precision coincidence of the mold platen at different position coordinates of stations, so as to be beneficial to realize the automation of the production of the preformed part.

Owner:CHINA MINSHENG ZHUYOU

Material feeding amount control device and method applied to die cutting machine

The invention relates to a material feeding amount control device and method applied to a die cutting machine. Thematerial feeding amount control device comprises a marking mechanism disposed on a feeding platform of the die cutting machine and a mark inspection mechanism located downstream of the marking mechanism. The relative position of the marking mechanism and the mark inspection mechanism can be adjusted, the marking mechanism can mark a film type material, and the mark inspection mechanism detects marks downstream.The control method includes the steps that a, the material is positionedand marked upstream of a die pressing system; b, the marks on the material aredetected upstream of the die pressing system; c, material feeding isstopped when the marks are detected, and then the material is simultaneously punched, position and marked; and d,after punching of the material is completed, the material feeding isstarted again, and then the steps b and c areconducted again until the material is all punched. The marking mechanism and the mark inspection mechanism are used for controlling the feeding amount of the diecutting machine for each die pressing, thereby improving the feeding precision of the diecutting machine.

Owner:无锡市正先自动化设备有限公司

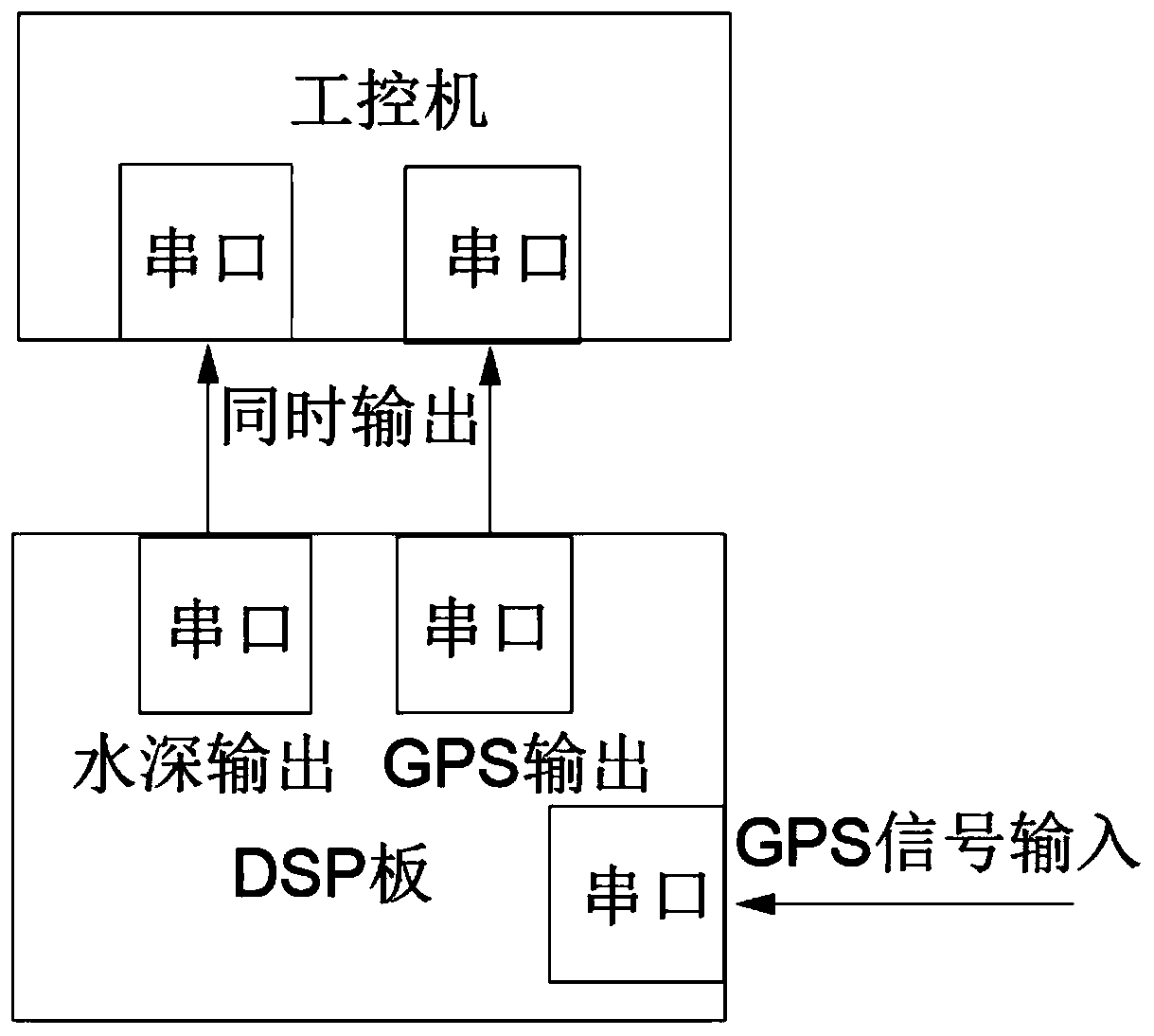

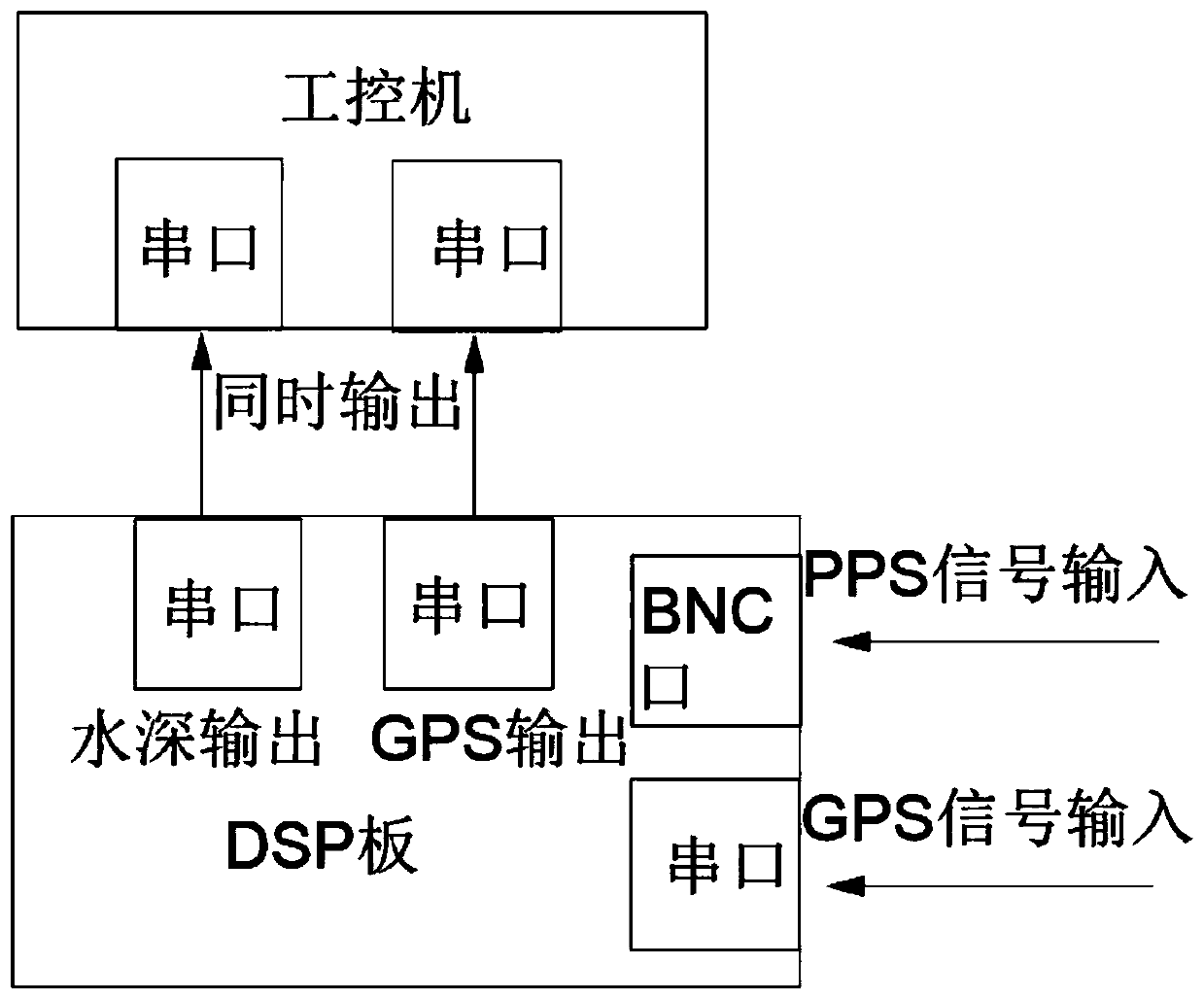

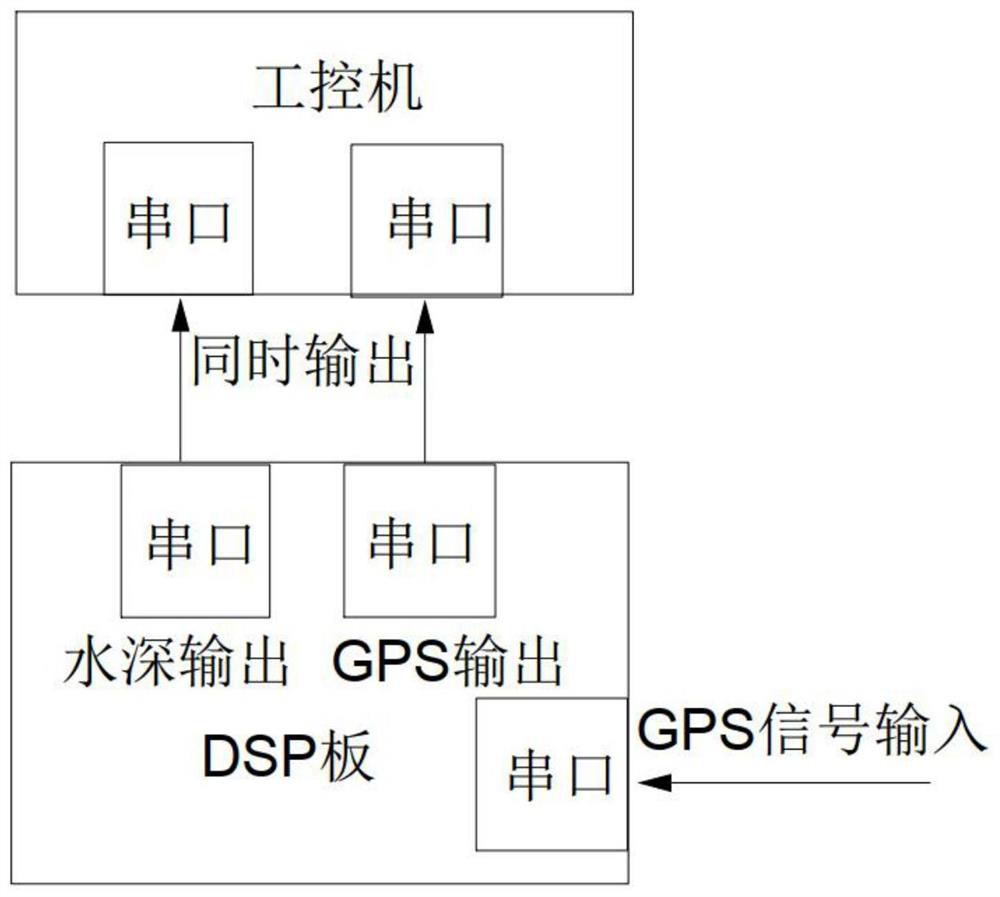

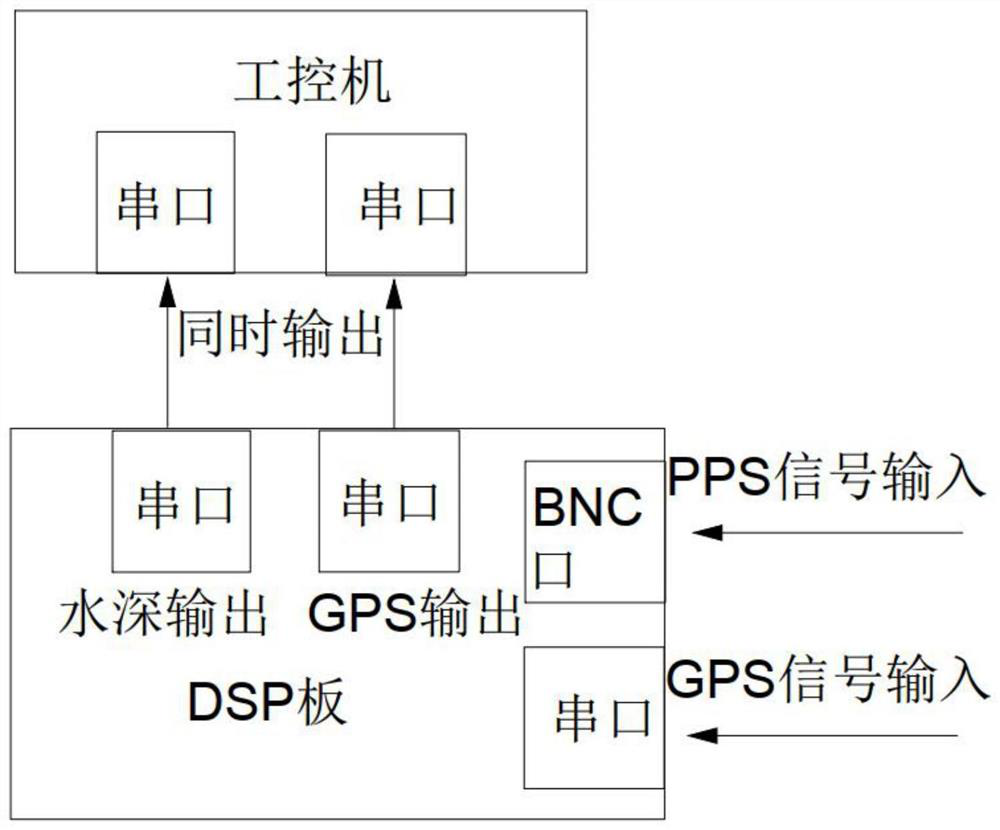

GPS-based water depth synchronization method and equipment

ActiveCN110645966AEliminate error factorsQuick and easy water depth measurementMeasuring open water depthWater resource assessmentEngineeringRemote sensing

The invention discloses a GPS-based water depth synchronization method. The method comprises the following steps of step S1, continuously transmitting a GPS signal to a DSP board by a GPS; and step S2, according to the transmission frequency of the GPS signal, taking a time interval from transmitting the signal by a depth finder to receiving a water depth signal as an estimated value to increase the estimated value before the GPS signal arrives and adjust the transmitted signal of the depth finder, so that the DSP board simultaneously receives the water depth signal and the GPS signal and synchronously sends the water depth signal and the GPS signal to an industrial personal computer. According to the GPS-based water depth synchronization method provided by the invention, the GPS and a water depth measurement technology are combined synchronously, some previous error factors are eliminated, and an increasing role in the future surveying and mapping industry is achieved; and the GPS technology is used for water depth measurement, so that the water depth measurement engineering becomes simple, fast and efficient. Therefore, the GPS and the water depth synchronization technology provide a high-precision, high-quality and high-benefit application prospect for fairway water depth measurement.

Owner:WUXI HAIYING CAL TEC MARINE TECH

A construction method for a large-diameter thick-walled continuous Y-shaped steel pipe column

ActiveCN112554577BGuaranteed positioningGuaranteed fixed effectStrutsBuilding material handlingThick wallPipe

The invention discloses a construction method of a large-diameter thick-wall continuous Y-shaped steel pipe column. The construction method is as follows: a BIM model of the continuous Y-shaped steel pipe column is established, and the continuous Y-shaped steel pipe column is decomposed into n prefabricated steel pipe columns from bottom to top. Buried pipe section, n Y-shaped column sections, 2n inclined column sections and n‑1 inverted V-shaped column sections; blanking to make each section; overall pre-assembly; quality inspection of pre-assembly; Coating, numbering, packaging, and transportation to the installation site; each pre-embedded pipe section and the corresponding Y-shaped column section are assembled into the lower part on site, and the two inclined column sections and the corresponding inverted V-shaped column section are assembled into the upper part; Hoist all the lower parts; hoist an upper part; then hoist another upper part adjacent to the previous upper part in turn to complete the hoisting of all upper parts; perform welding. The construction method not only has high processing quality and is convenient for transportation, but also can adjust the installation angle of the inclined column, and has a short construction period and high construction efficiency.

Owner:中冶建工集团重庆建筑工业有限公司

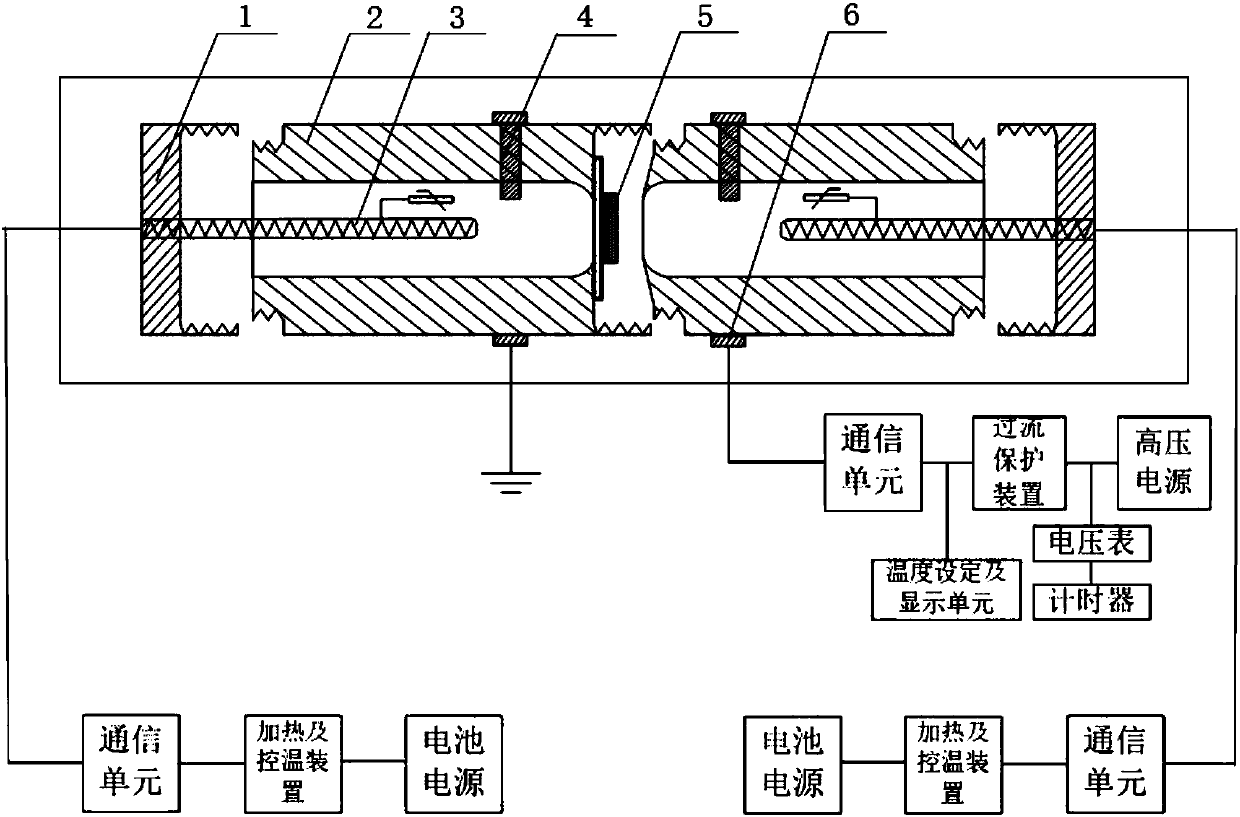

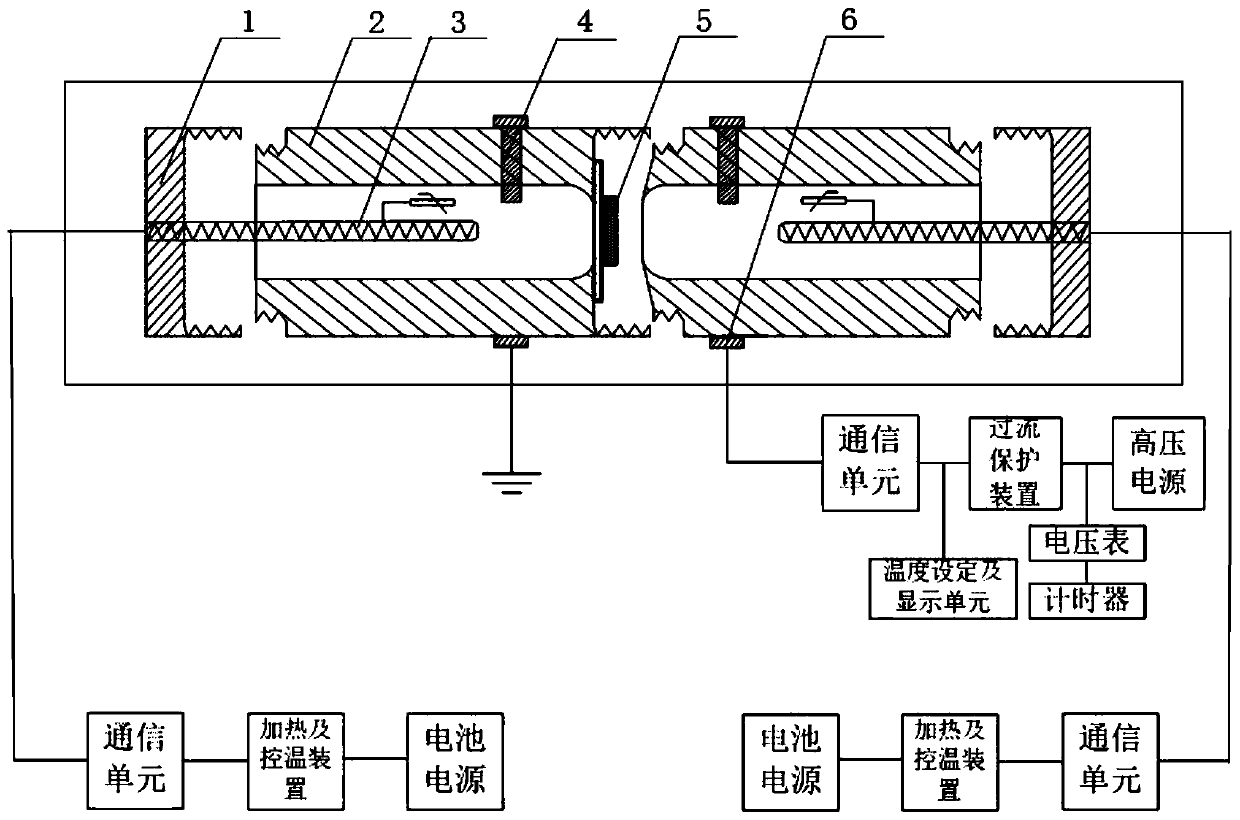

Intelligent temperature-adjusting and voltage-adjusting XLPE (cross-linked polyethylene) cable insulation material performance tester

ActiveCN107870289AReasonable designOvercoming the phenomenon of large temperature conduction errorTesting dielectric strengthCommunication unitError factor

The invention relates to an intelligent temperature-adjusting and voltage-adjusting XLPE (cross-linked polyethylene) cable insulation material performance tester. The tester has the technical characteristics of comprising two cup bodies of which the bottoms are provided with round openings, the bottoms of the two cup bodies are jointly connected back to back in a rotational thread mode, the cup openings and cup covers of the cup bodies are installed together in a thread mode, each cup body is internally filled with a Nacl solution to serve as a conducting medium, the surfaces of the cup bodiesare provided with small holes which are used for enabling two high-voltage electrodes to stretch into the interiors of the two cup bodies, the high-voltage electrodes and a voltage-increasing deviceare mutually connected, the center of each cup cover is provided with a heating device which stretches into a cup body, the heating device is connected with a heating and control device and a batterypower source through a communication unit. The tester is reasonable in design, the error factors caused by different test conditions are eliminated, the voltage-resistant strength of XLPE in differentenvironmental temperature can be accurately tested, the goodness and badness of the insulation performance of an XLPE sample can be more accurately reflected, and the tester can be widely used for testing the insulation performance of the XLPE.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Method for Determination of Antioxidant Content in Lubricating Oil by Linear Sweep Voltammetry

ActiveCN104597101BImprove accuracyImprove applicabilityMaterial electrochemical variablesAntioxidantPeak area

The invention provides a method for measuring the antioxidant content in a lubricating oil by use of linear sweep voltammetry, and belongs to the technical field of electrochemical detection. The method comprises the following steps: adding an ethanol solution of which the antioxidant concentration is known to an electrolyte, measuring by use of the linear sweep voltammetry to obtain the characteristic voltage-current curve of the electrolyte, calculating the characteristic peak area of the curve, establishing a working curve of the antioxidant concentration and the characteristic peak area, extracting new lubricating oil with the known antioxidant content and lubricating oil with unknown antioxidant content by using ethanol, adding the supernatant liquid to the electrolyte, measuring by use of the linear sweep voltammetry to obtain the characteristic voltage-current curve of the electrolyte, calculating the characteristic peak area of the curve, and substituting the characteristic peak area of the known antioxidant into the working curve to obtain the correction coefficient of the lubricating oil of the antioxidant to obtain the unknown antioxidant content. The method is simple, convenient and quick to operate, and high in sensitivity, and can be widely applied to the measurement of the antioxidant content in synthetic oil or mineral oil lubricating oil and the rapid evaluation of the oxidative stability of the lubricating oil.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Intelligent temperature regulation, voltage regulation xlpe cable insulation material performance tester

ActiveCN107870289BReasonable designOvercoming the phenomenon of large temperature conduction errorTesting dielectric strengthCommunication unitVoltage regulation

The invention relates to an intelligent temperature-adjusting and voltage-adjusting XLPE (cross-linked polyethylene) cable insulation material performance tester. The tester has the technical characteristics of comprising two cup bodies of which the bottoms are provided with round openings, the bottoms of the two cup bodies are jointly connected back to back in a rotational thread mode, the cup openings and cup covers of the cup bodies are installed together in a thread mode, each cup body is internally filled with a Nacl solution to serve as a conducting medium, the surfaces of the cup bodiesare provided with small holes which are used for enabling two high-voltage electrodes to stretch into the interiors of the two cup bodies, the high-voltage electrodes and a voltage-increasing deviceare mutually connected, the center of each cup cover is provided with a heating device which stretches into a cup body, the heating device is connected with a heating and control device and a batterypower source through a communication unit. The tester is reasonable in design, the error factors caused by different test conditions are eliminated, the voltage-resistant strength of XLPE in differentenvironmental temperature can be accurately tested, the goodness and badness of the insulation performance of an XLPE sample can be more accurately reflected, and the tester can be widely used for testing the insulation performance of the XLPE.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

Error measuring device of weldless pipe continuous rolling mill roller and detecting method thereof

InactiveCN100540167CHigh precisionIncrease productionMeasuring devicesUsing fluid meansHydraulic cylinderHydraulic pump

The invention relates to a detection device and method for deviations in rolls of seamless pipe tandem mill. A lifting hydraulic cylinder and an impelling hydraulic cylinder which are respectively equipped with a displacement sensor and fixed on a detection frame body are connected with a computer through a cable, and are also communicated with a hydraulic pump. A roller and a bearing box are arranged on the detection frame body, the impelling hydraulic cylinder presses the roll ring of the roller onto a slide; the displacement sensor respectively inputs the detected values into the computer for conversion and sorting, then the actual deviations of the top nest work surface of the bearing box from the centre line of the roller is obtained. The lifting hydraulic cylinder makes the pass template to adhere to the pass of the roller, the displacement sensor inputs the detected values into the computer for sorting out, and the actual deviations of the cushion work surface of the bearing box from the pass centre of the roller can be obtained. The invention eliminates various mechanical clearances, excludes any artificial error and removes any hidden danger, improves the measurement accuracy by 2 to 3 times than the artificial measuring way, and the detection time can be shortened by 5 hours.

Owner:ANGANG STEEL CO LTD

A material feed control device and control method applied to a die-cutting machine

The invention relates to a material feeding amount control device and method applied to a die cutting machine. Thematerial feeding amount control device comprises a marking mechanism disposed on a feeding platform of the die cutting machine and a mark inspection mechanism located downstream of the marking mechanism. The relative position of the marking mechanism and the mark inspection mechanism can be adjusted, the marking mechanism can mark a film type material, and the mark inspection mechanism detects marks downstream.The control method includes the steps that a, the material is positionedand marked upstream of a die pressing system; b, the marks on the material aredetected upstream of the die pressing system; c, material feeding isstopped when the marks are detected, and then the material is simultaneously punched, position and marked; and d,after punching of the material is completed, the material feeding isstarted again, and then the steps b and c areconducted again until the material is all punched. The marking mechanism and the mark inspection mechanism are used for controlling the feeding amount of the diecutting machine for each die pressing, thereby improving the feeding precision of the diecutting machine.

Owner:无锡市正先自动化设备有限公司

Shaft and rod micro-clearance direct-connection technology

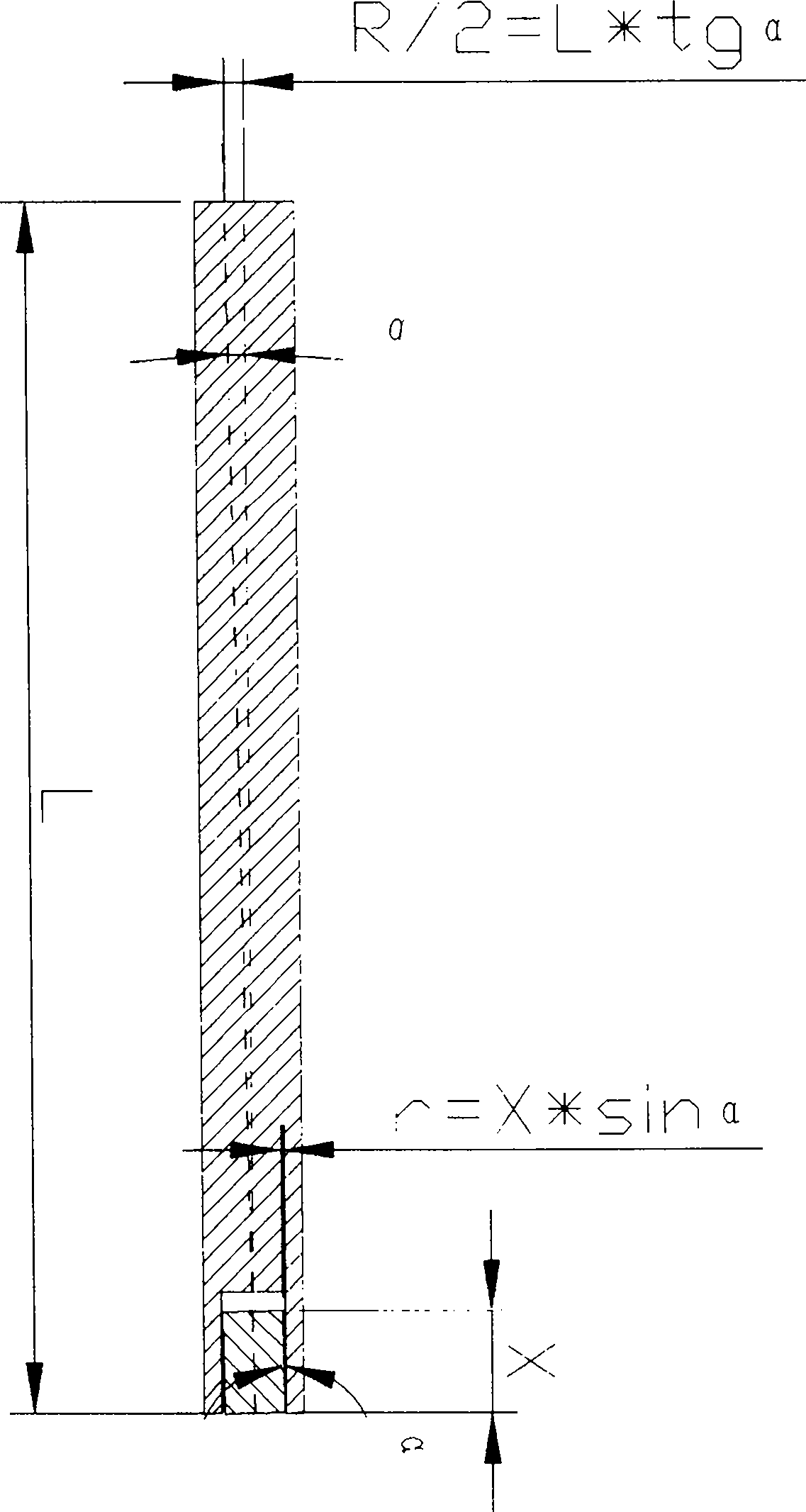

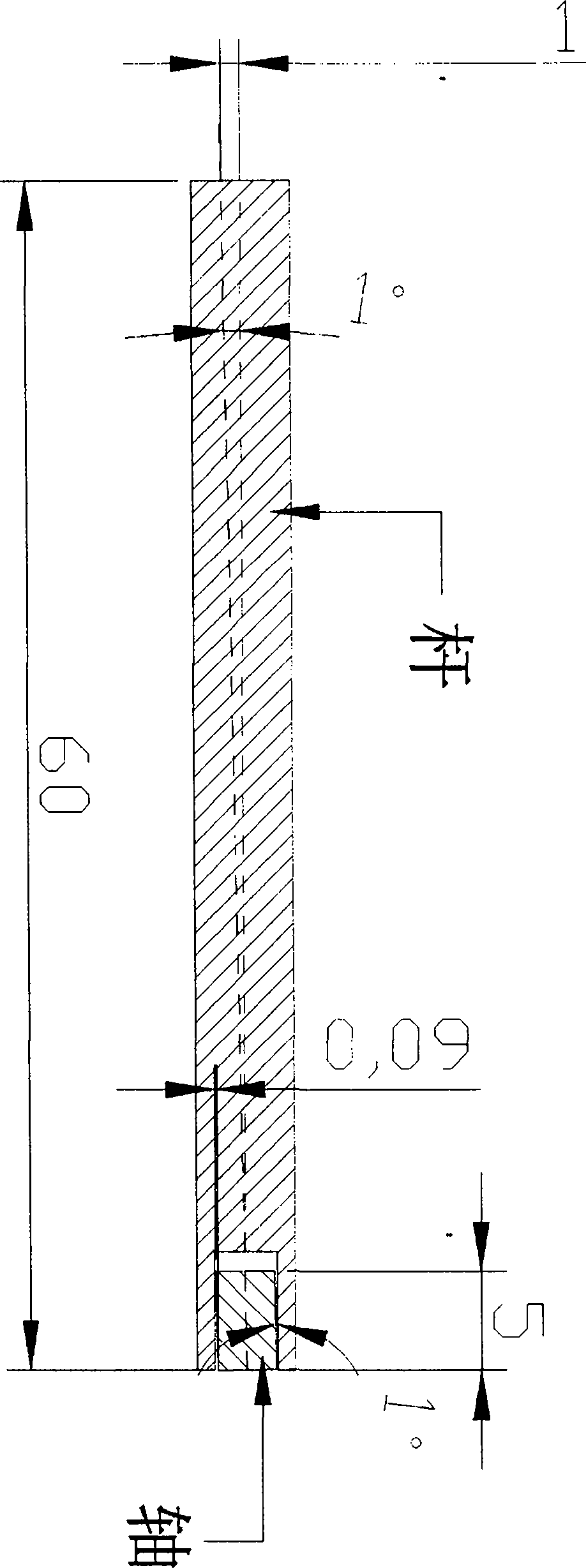

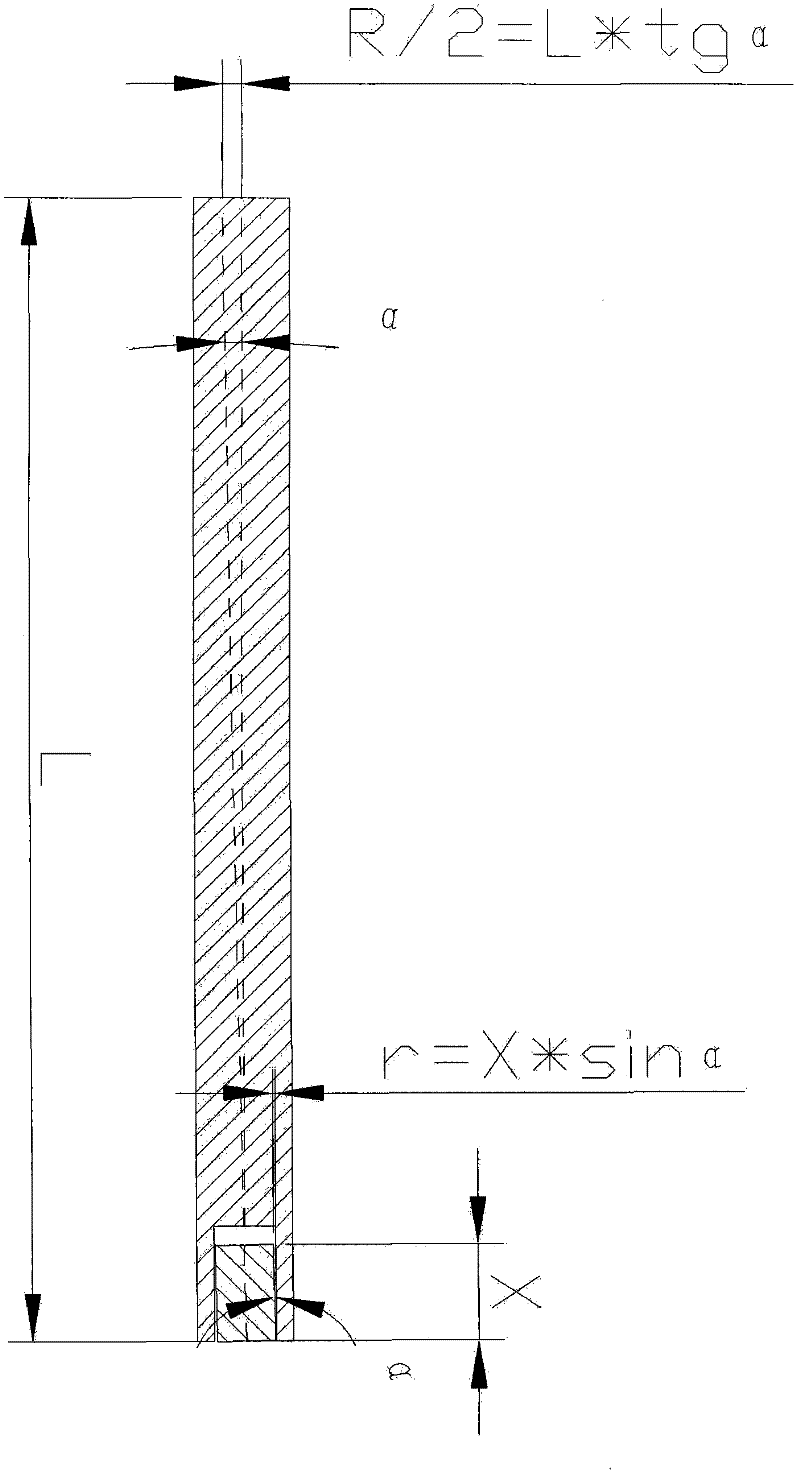

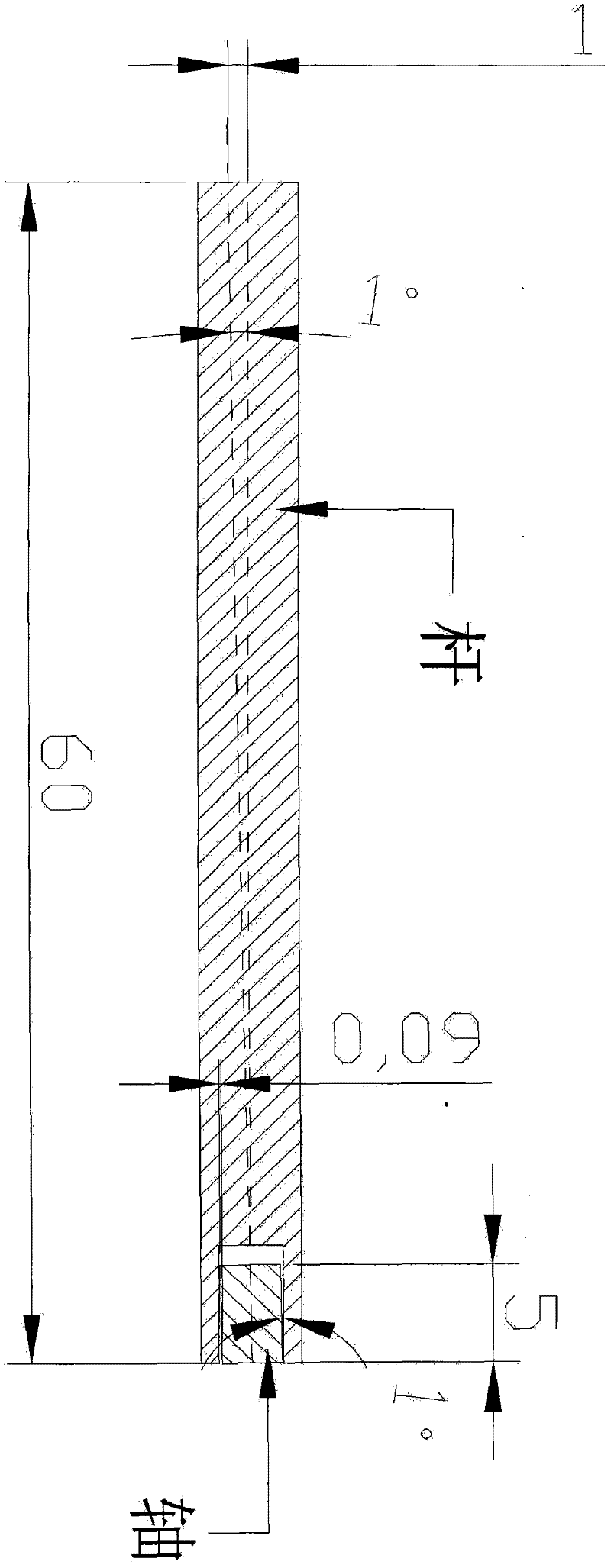

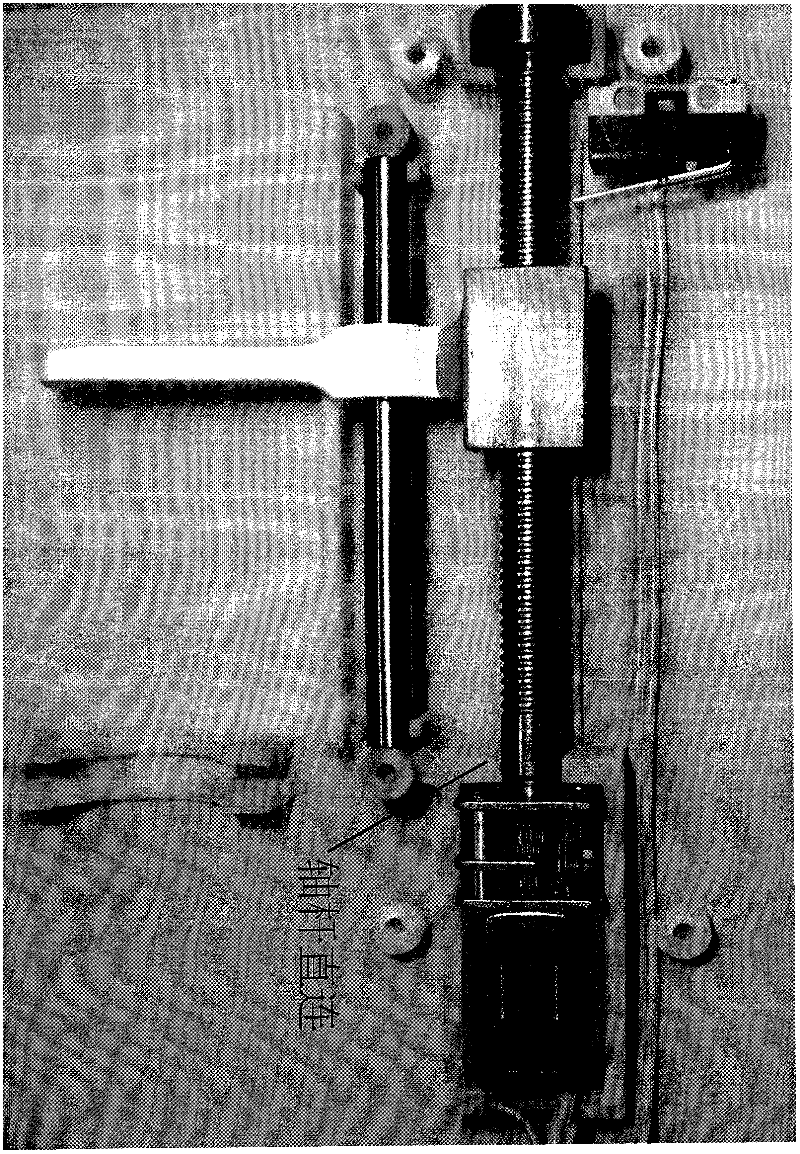

The invention relates to a micro-interval shaft lever direct connection method which reserves intervals at the connection of the shaft and the lever, thus eliminates the deviation caused by offset and an included angle between a shaft central line and a lever central line, eliminates the deviation caused by shaft radial direction jump and axial direction endplay, eliminates the bad factors brought by assembly location deviation, enables the lever not to shake and not to generate the bad reaction force, and greatly improves the transmission stability and efficiency. It is important to obtain the reserved intervals. Though interference fit of the shaft lever, the farthest end shaking amplitude of the lever is measured after running, namely the shaking maximum diameter is R, the lever length is set as L, alpha is obtained according to tg alpha=R / 2L, the length of the shaft into the lever is set as x, then the reserved interval r of the shaking part is x*sina alpha, the alignment deviation caused by the assembly is set as y, then the minimum interval between the shaft and the lever is x*sina alpha+2y, and normally unpredictable interval z of 0.01-0.05mm is also needed to improve the reliability.

Owner:张文玺

Shaft and rod micro-clearance direct-connection technology

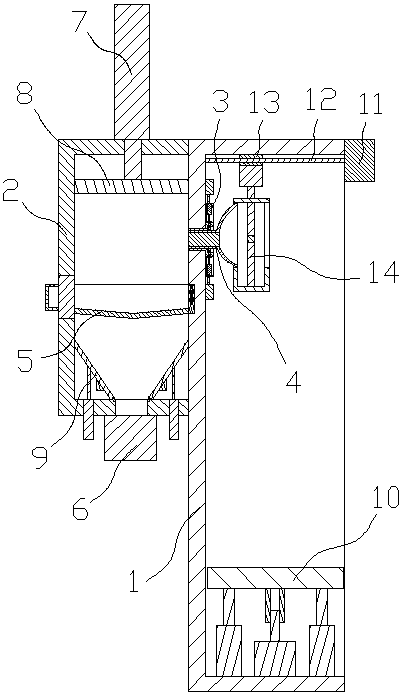

The invention relates to the field of mechanical transmission, in particular to a shaft and rod micro-clearance direct-connection technology, which is applied to situations having certain requirements for space and reduction of energy consumption. The shaft and rod micro-clearance direct-connection technology includes that a hole matched with a non-cylindrical shaft (which can be D-shaped or double-D-shaped) is manufactured at one end of a rod, the circle center of the camber surface of the hole is concentric with the rod, and a clearance is reserved between the hole and the shaft, so that error caused by deviation and included angle between the center line of the shaft and the center line of the rod can be eliminated, shake of the rod and defective stress are avoided, stability and efficiency in transmission are improved greatly. Since the shaft and the rod are connected directly without any intermediate link, space occupation is minimized, and the problem of doubled error caused in conventional connection of the shaft and the long rod is solved.

Owner:张文玺

Dust mask effect demonstration machine capable of realizing concentration regulation of different dust particles

InactiveCN108492703AGood and convenient concentration adjustment effectSimple structureEducational modelsEngineeringDust particles

The invention relates to a dust mask effect demonstration machine capable of realizing concentration regulation of different dust particles. The dust mask effect demonstration machine comprises a demonstration cabinet and a dust particle cabinet, wherein a communicating hole matched with the dust particle cabinet is formed in the left side wall of the demonstration cabinet, a dust mask is in fit in the communicating hole and is clamped by a mask clamping mechanism in the demonstration cabinet, a dust particle picking and placing device is arranged at a part, located below the communicating hole, of the dust particle cabinet, a base plate of the dust particle picking and placing device is a ventilation plate, a dust blowing air port is formed in the lower side of the dust particle cabinet,the dust blowing air port is communicated with a dust blowing fan, a concentration regulating air cylinder which is a vertical trend and penetrates the interior of the dust particle cabinet is arranged at the upper part of the dust particle cabinet, and a concentration regulating block in seal fit with the dust particle cabinet is connected below the concentration regulating air cylinder. The dustmask effect demonstration machine provided by the invention has the advantages that the concentration regulating block is controlled to go up and down by virtue of the concentration regulating air cylinder, further volume of a dust particle cavity is regulated, the effect of regulating concentrations of the dust particles is achieved, the condition that quantity of the dust particles is too largeand beyond a blowing range of the fan cannot occur, and then the good and convenient dust particle concentration regulating effect is realized.

Owner:DONGGUAN UNIV OF TECH

Device for detecting hole site depth of vehicle lights

InactiveCN101251363BGuaranteed tightnessExtended service lifeElectric/magnetic depth measurementObservational errorLight fixture

The invention discloses an automobile lamp hole site depth detection device, which comprises a load bearing mainboard, a power supply device arranged on the load bearing mainboard, an indicator light and depth detection craft equipment for metal positive and negative electrodes, wherein, the depth detection craft equipment for metal positive and negative electrodes is connected with the indicatorlight through a power supply line and forms a circuit with the power supply device. During the detection, whether the depth of an automobile lamp hole site reaches the requirement is judged through the contact state of the detection craft equipment. The invention is suitable for the detection of various automobile lamp hole sites. The automobile lamp hole site depth detection device has the advantages of simple structure, convenient and quick operation and small measurement error.

Owner:山东鲁得贝车灯股份有限公司

Device for detecting hole site depth of vehicle lights

InactiveCN101251363AGuaranteed tightnessExtended service lifeElectric/magnetic depth measurementObservational errorEngineering

The invention discloses an automobile lamp hole site depth detection device, which comprises a load bearing mainboard, a power supply device arranged on the load bearing mainboard, an indicator light and depth detection craft equipment for metal positive and negative electrodes, wherein, the depth detection craft equipment for metal positive and negative electrodes is connected with the indicator light through a power supply line and forms a circuit with the power supply device. During the detection, whether the depth of an automobile lamp hole site reaches the requirement is judged through the contact state of the detection craft equipment. The invention is suitable for the detection of various automobile lamp hole sites. The automobile lamp hole site depth detection device has the advantages of simple structure, convenient and quick operation and small measurement error.

Owner:山东鲁得贝车灯股份有限公司

Mold table positioning method on prefabricated parts production line

ActiveCN111775301BPrevent deviationEliminate error factorsTelevision system detailsMoulding surfacesData controlProduction line

Owner:CHINA MINSHENG ZHUYOU

A GPS-based water depth synchronization method and device

ActiveCN110645966BEliminate error factorsQuick and easy water depth measurementMeasuring open water depthWater resource assessmentTelecommunicationsBathymetry

The invention discloses a water depth synchronization method based on GPS, comprising the following steps: S1, GPS continuously transmits GPS signals to a DSP board; The time interval is used as an estimated value, and the estimated value is increased before the arrival of the GPS signal to adjust the emission signal of the depth sounder, so that the DSP board receives the water depth signal and the GPS signal at the same time, and sends the water depth signal and the GPS signal to the industrial computer synchronously. The present invention combines GPS and water depth measurement technology synchronously, eliminates some error factors that existed before, and will play an increasingly important role in the surveying and mapping industry in the future. Using GPS technology for water depth measurement makes the project of water depth measurement easier , fast and efficient. Therefore, GPS and depth synchronization technology will provide high-precision, high-quality and high-efficiency application prospects for channel bathymetry.

Owner:WUXI HAIYING CAL TEC MARINE TECH

Waveform monitor apparatus of injection molding machine

When a waveform monitor apparatus 1 of an injection molding machine M for monitoring an operation waveform at least during molding is configured by mounting the waveform monitor apparatus 1 on the injection molding machine M for performing molding according to a specific molding system, a parting opening detecting means Fp for detecting change data of a parting opening Lm to a time during molding, and an operation waveform displaying means Fd for displaying at least change data from a resin filling start is into a mold 2 to a cooling time termination to of the mold 2, detected by the parting opening detecting means Fp, on a waveform displaying portion 5 of a screen 4v on a display 4 attached to a molding machine controller 3 are provided.

Owner:NISSEI PLASTIC IND CO LTD

Detection device for end face runout value of structural member

PendingCN107504879AImprove stabilityEliminate error factorsMechanical measuring arrangementsEngineeringRotational axis

The invention discloses a detection device for an end face runout value of a structural member. The detection device includes a fixed base plate fixed on a workbench. A fixed housing is arranged on the fixed base plate. A bearing is arranged in the fixed housing. A rotating shaft is fixed on the bearing. The two ends of the rotating shaft extend out of the fixed housing. The detection device also includes a test tool, which includes an indicating gauge and an indicating gauge support. The indicating gauge support is fixed on the fixed base plate or the workbench. The test tool is fixed on the workbench, exhibits good stability, and helps to eliminate factors of errors. The detection device is convenient to operate, and a to-be-detected product is dismounted on the rotating shaft only by hands. Skill requirements for operators are reduced.

Owner:海宁科巍轴承科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com