Method for measuring antioxidant content in lubricating oil by use of linear sweep voltammetry

A linear scanning, antioxidant technology, applied in the field of electrochemical detection, can solve the problems of high test cost of high performance liquid chromatography, long operation time of thin layer chromatography, unsuitable type for the determination of antioxidants, etc., to improve the sensitivity , the measurement process is rigorous, and the effect of expanding the applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

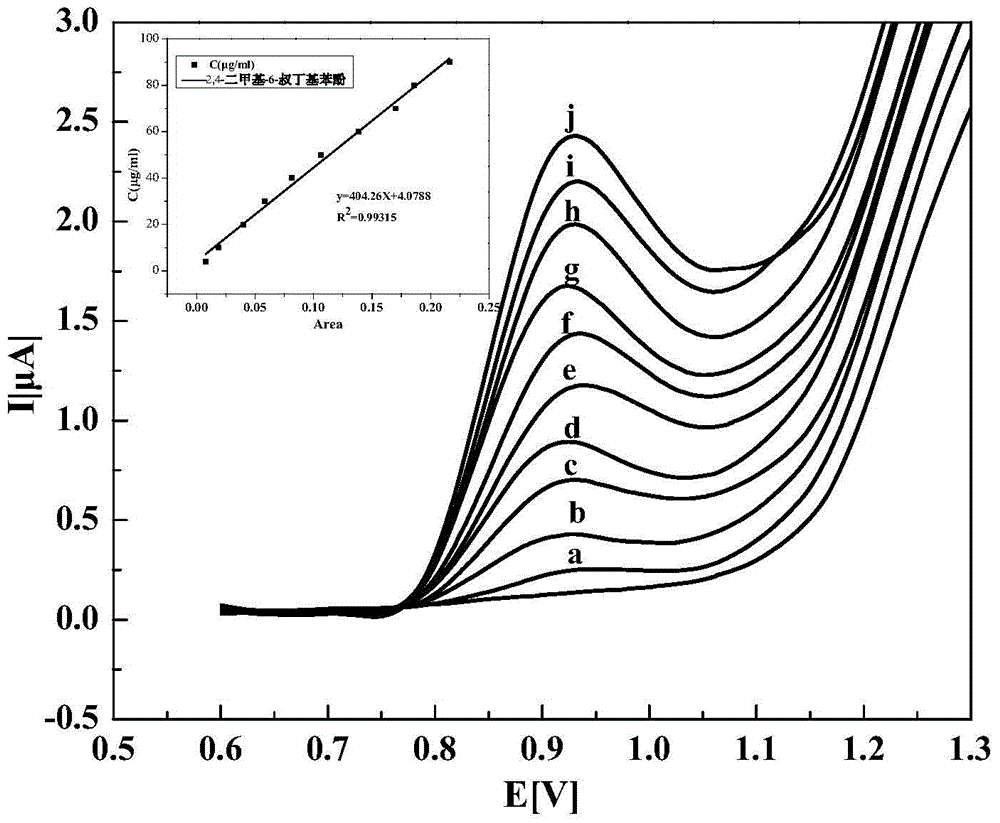

[0036]Determination of antioxidant 2,4-dimethyl-6-tert-butylphenol in trimethylolpropane oleate (TMPTO) at aging temperature of 120°C under different aging times:

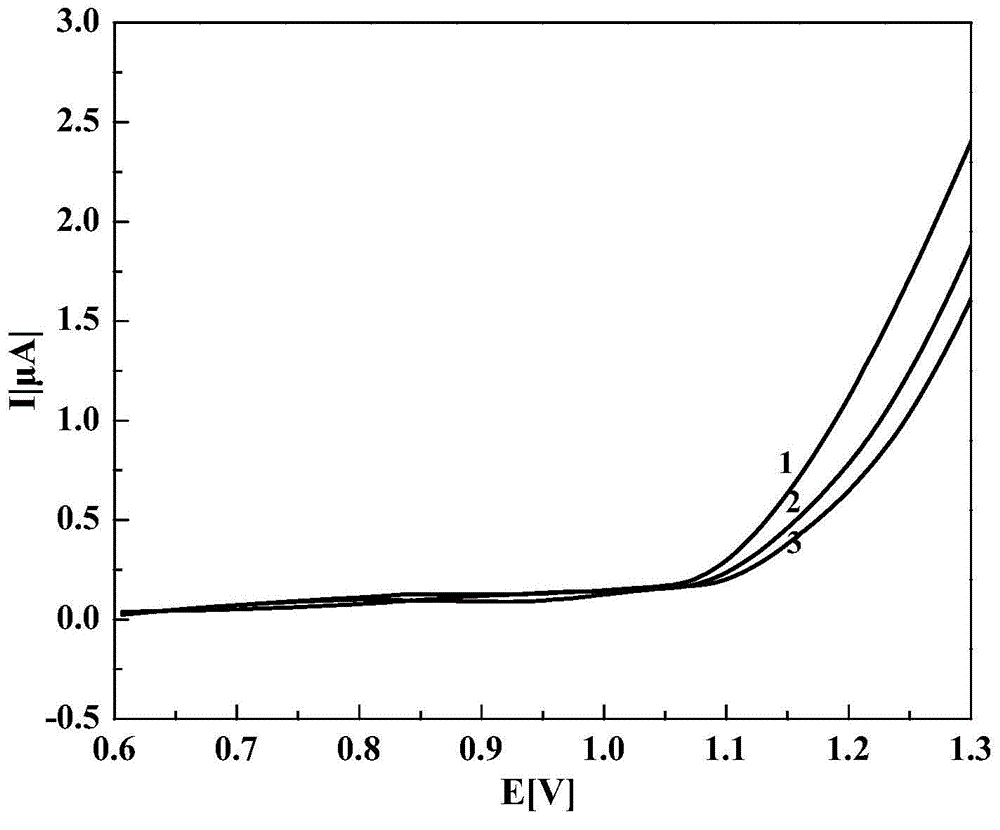

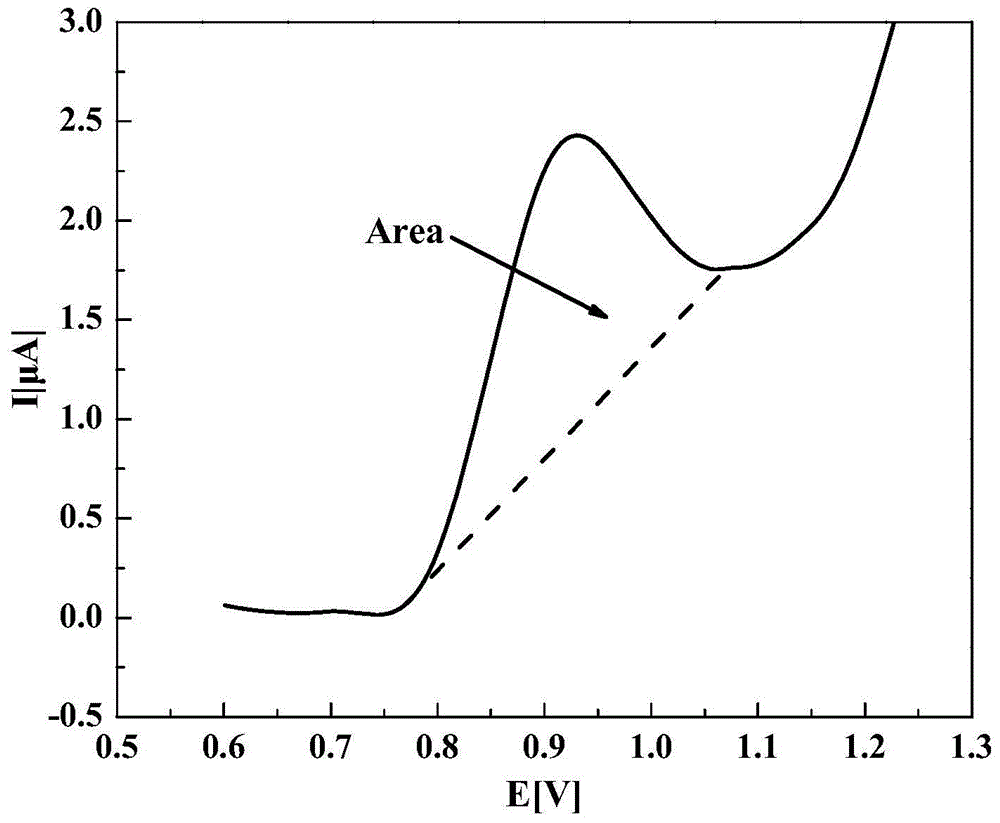

[0037] The TMPTO containing 1% by mass of 2,4-dimethyl-6-tert-butylphenol was aged in an oven at 120°C, and the aging time was 14h, 24h, 48h, 73h, 96h, 120h TMPTO sample. Adopt PARSTAT 2273 electrochemical workstation, the 96% (volume fraction) ethanol solution of the 2,4-dimethyl-6-tert-butylphenol of standard sample 2mg / ml of different volumes is added to containing 10ml self-made sulfuric acid, anhydrous In the electrolytic cell of the acidic electrolyte solution of ethanol and sodium dodecylsulfonate, stir it evenly with a glass rod, let it stand for a while, insert a three-electrode system, in which the working electrode is a gold disc electrode, the auxiliary electrode is a platinum sheet, and the reference Electrode is Ag / AgCl, adopts linear sweep voltammetry to sweep from 0.6v to 1.6v with the scanning spe...

Embodiment 2

[0043] Determination of antioxidant 2,4-dimethyl-6-tert-butylphenol in mineral oil (500SN) at aging temperature of 120°C under different aging times:

[0044] Mineral oil (500SN) containing 1% by mass of 2,4-dimethyl-6-tert-butylphenol was aged in an oven at 120°C, and the collection aging time was 14h, 24h, 73h, 96h, 120h of mineral oil (500SN) samples. Using PARSTAT 2273 electrochemical workstation, add different volumes of 2mg / ml standard 2,4-dimethyl-6-tert-butylphenol 96% ethanol solution to 10ml homemade sulfuric acid, absolute ethanol and dodecyl In the electrolytic cell of the acidic electrolyte solution of sodium alkyl sulfonate, stir evenly with a glass rod, let it stand for a while, insert a three-electrode system, wherein the working electrode is a gold disc electrode, the auxiliary electrode is a platinum sheet, and the reference electrode is Ag / AgCl, adopt linear sweep voltammetry to sweep from 0.6v to 1.6v with the scanning speed of 5mv / s, obtain the character...

Embodiment 3

[0050] Determination of antioxidant T501 under different aging times in mineral oil (500SN) at 120°C aging temperature:

[0051] Mineral oil (500SN) containing 1% by mass of T501 was aged in an oven at 120°C, and samples of mineral oil (500SN) were collected with aging times of 14h, 24h, 73h, 96h, and 120h. Adopt PARSTAT 2273 electrochemical workstation, join the 96% ethanol solution of the T501 of the standard sample 2mg / ml of different volumes in the electrolytic cell that contains 10ml self-made sulfuric acid, absolute ethanol and sodium dodecylsulfonate electrolyte, use Stir the glass rod evenly, let it stand for a while, and insert it into a three-electrode system, in which the working electrode is a gold disc electrode, the auxiliary electrode is a platinum sheet, and the reference electrode is Ag / AgCl. Linear sweep voltammetry is used at a scanning speed of 5mv / s Sweep from 0.6v to 1.6v, obtain the characteristic voltammetry curves of different concentrations of T501 (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com