Intelligent temperature regulation, voltage regulation xlpe cable insulation material performance tester

A technology for cable insulation and material properties, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve problems such as test result errors, uneven temperature, high density of insulating oil, etc., to overcome large temperature conduction errors and overcome contact area Small, accurate insulation performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

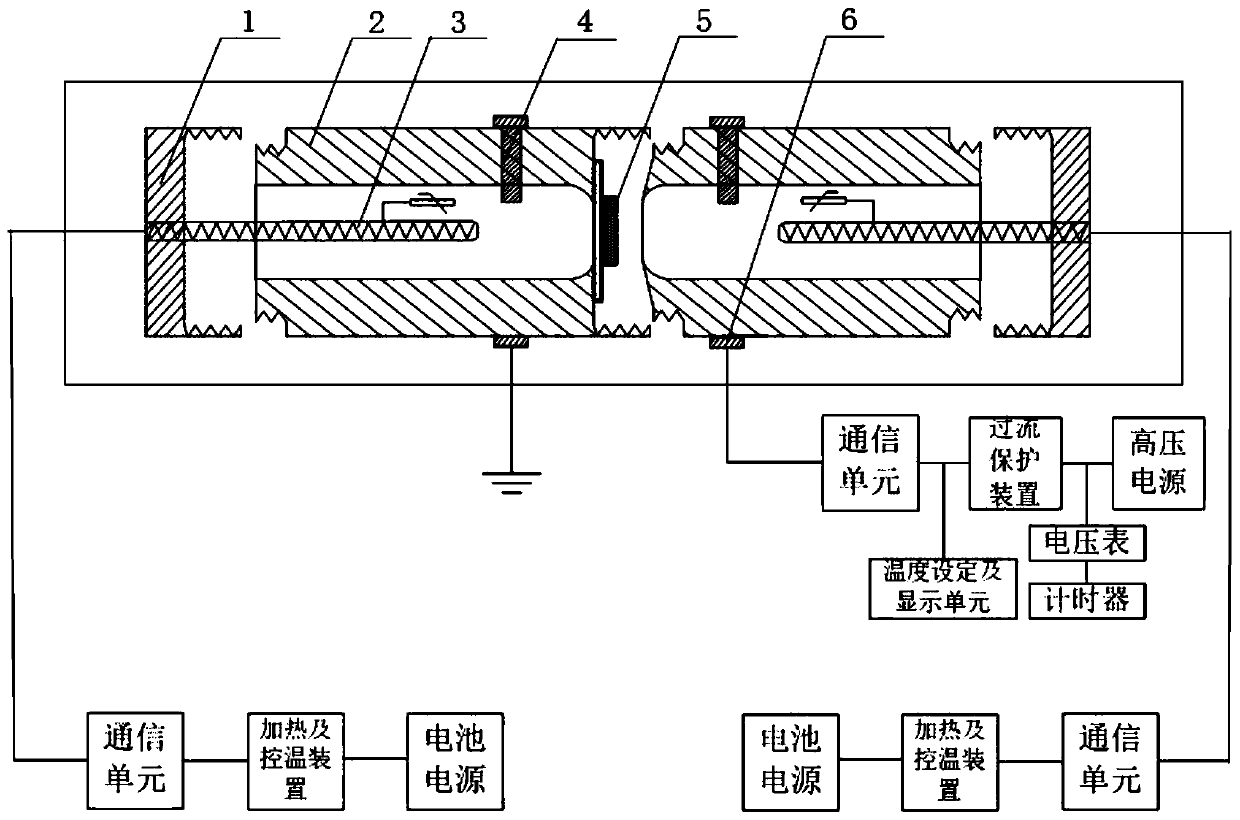

[0014] An intelligent temperature-regulating and voltage-regulating XLPE cable insulation material performance tester, such as figure 1 As shown, there are two cup bodies 2 with circular openings at the bottom, and the bottoms of the two cup bodies are connected back to back by rotating threads. During the test, the XLPE sample 5 is placed in the circle where the two cup bodies overlap shape opening. The mouth of the cup body and the cup cover 1 are threaded together, and each cup body is filled with Nacl solution as a conductive medium. There are small holes on the surface of the cup body for probing the two high-voltage electrodes 4 into the two cup bodies respectively. In order to facilitate the test wiring, connect the high-voltage electrodes in the cup body with the hoop-shaped metal ring 6 close to the outside of the cup body. Achieve h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com