Device for detecting hole site depth of vehicle lights

A technology for depth detection and car lights, applied in electromagnetic measuring devices, electric/magnetic depth measurement, etc., can solve problems such as unsatisfactory assembly effects and large measurement errors, achieve intuitive detection results, ensure sealing, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

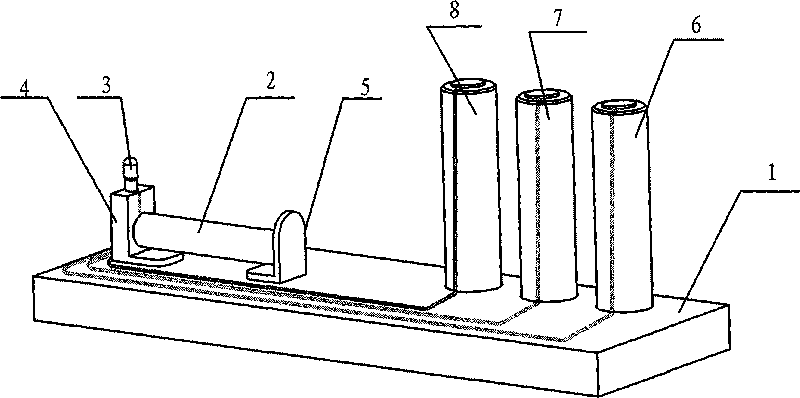

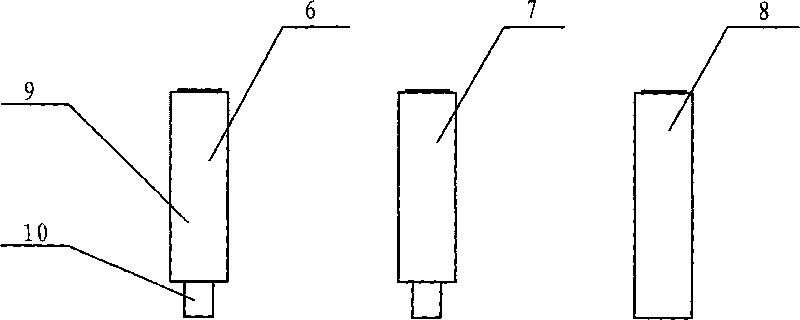

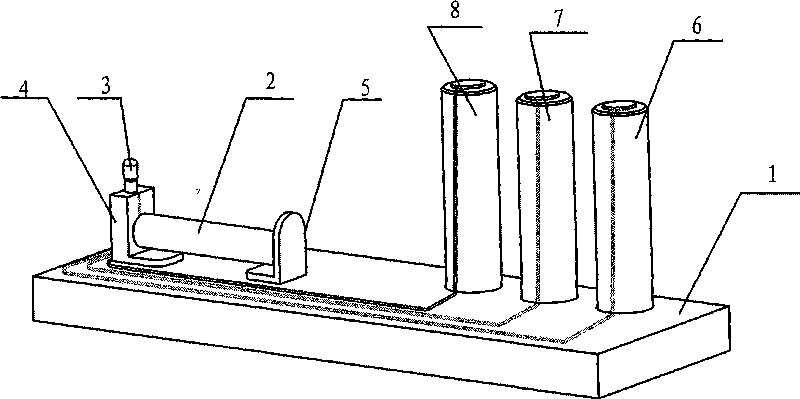

[0013] As shown in the accompanying drawings, a device for detecting the depth of a car lamp hole position includes a main board 1, an LED power supply 2 arranged on the main board 1, an LED indicator light 3, a positive contact piece 4, a negative contact piece 5, and a metal positive electrode. The depth detection tooling 6, 7 and the negative electrode depth detection tooling 8, the metal positive and negative electrode depth detection tooling are connected to the indicator light through the power line, and form a circuit with the power supply. The positive electrode depth detection tool has two sizes and specifications, wherein the positive electrode depth detection tool 7 is the negative deviation size of the design size, and the positive electrode depth detection tool 6 is the positive deviation size of the design size. The positive detection tooling includes a cylindrical grip 9 and a cylindrical detection part 10, the outer diameter of the grip 9 is larger than the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com