A material feed control device and control method applied to a die-cutting machine

A control device and feed rate technology, applied in thin material processing, positioning objects, transportation and packaging, etc., can solve the problem that the feeding accuracy cannot meet the needs of production, achieve smooth and clear marking boundaries, improve detection accuracy, and improve supply. The effect of material accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

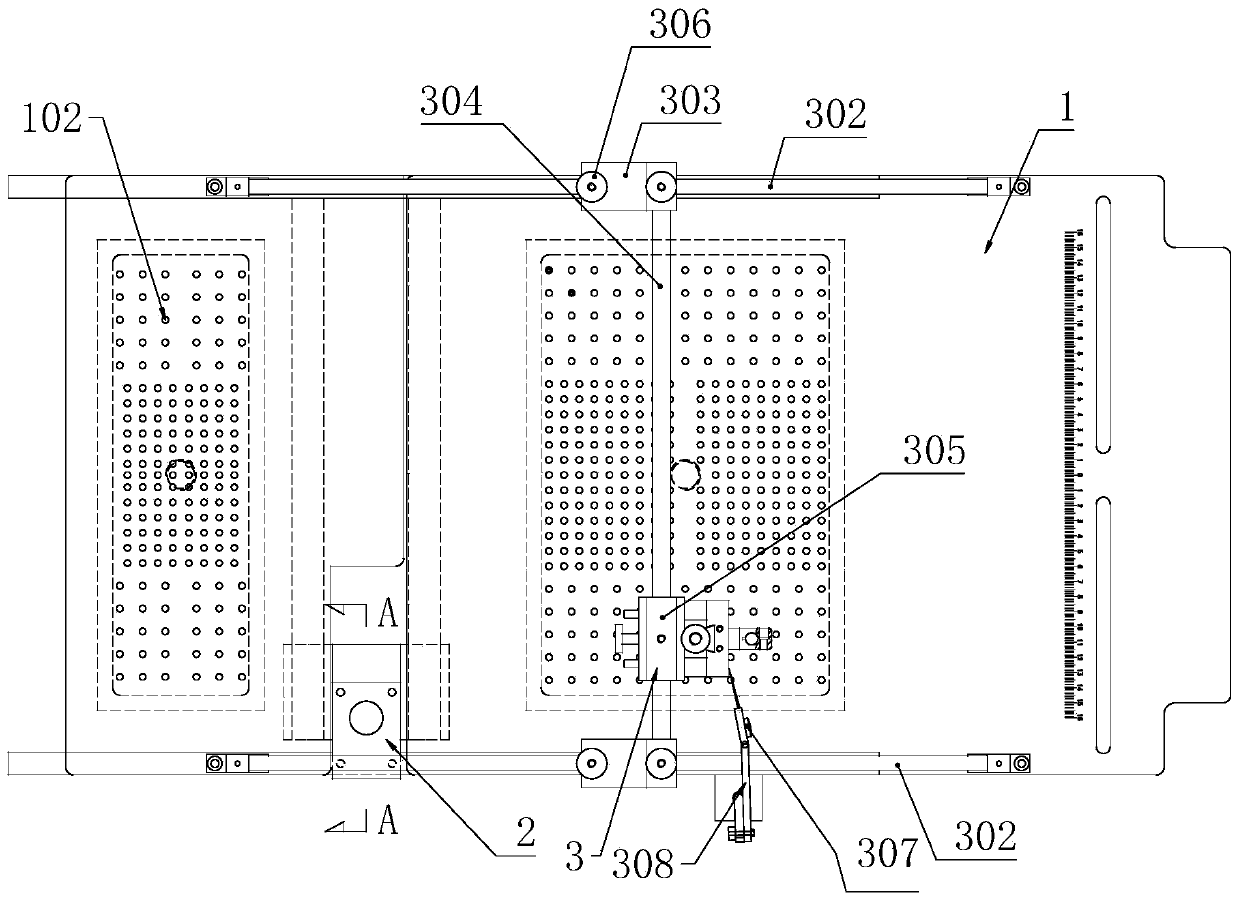

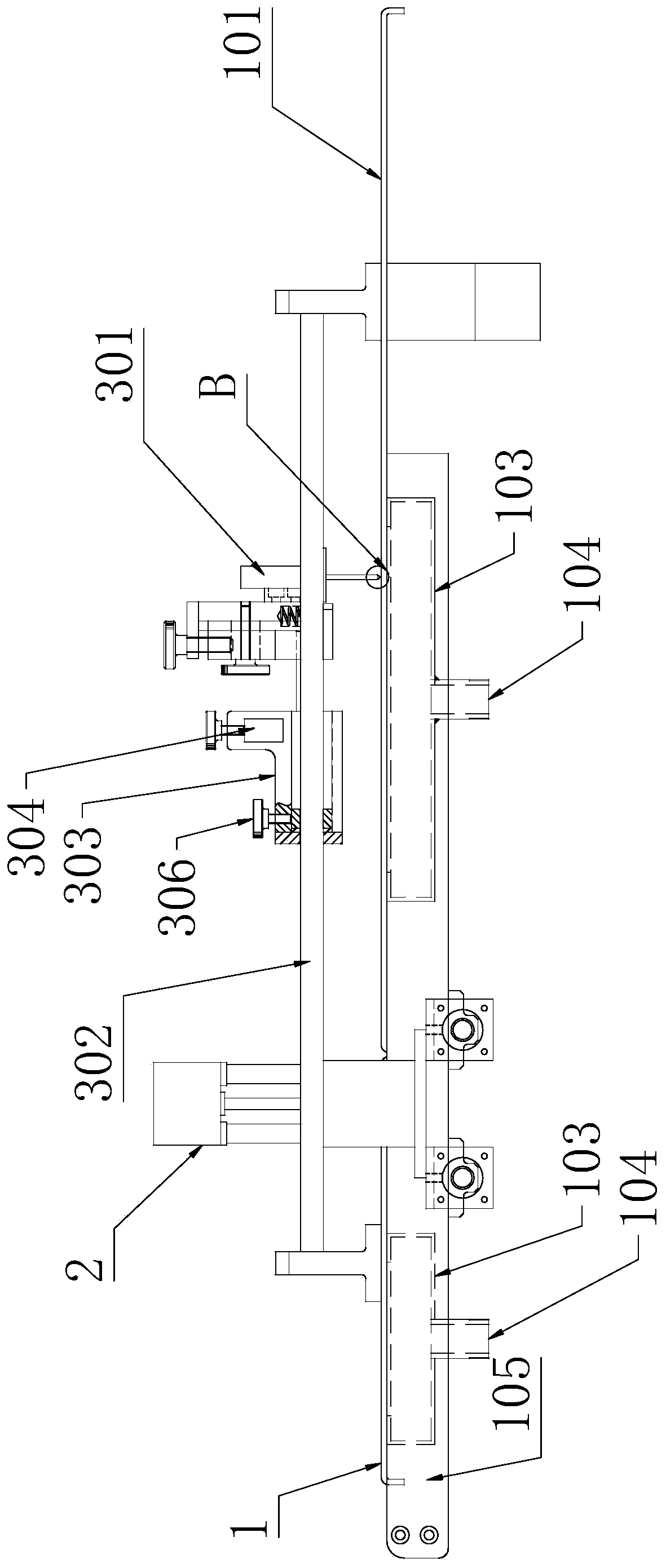

[0039] like figure 1The shown feed positioning device applied to a die-cutting machine includes a marking mechanism 2 arranged on a feeding platform 1 of a die-cutting machine and a marking mechanism 3 located downstream of the marking mechanism 2. The marking mechanism 2 The relative position of the marking mechanism 3 can be adjusted, the marking mechanism 2 can mark the film-type material, and the marking mechanism 3 detects the mark downstream.

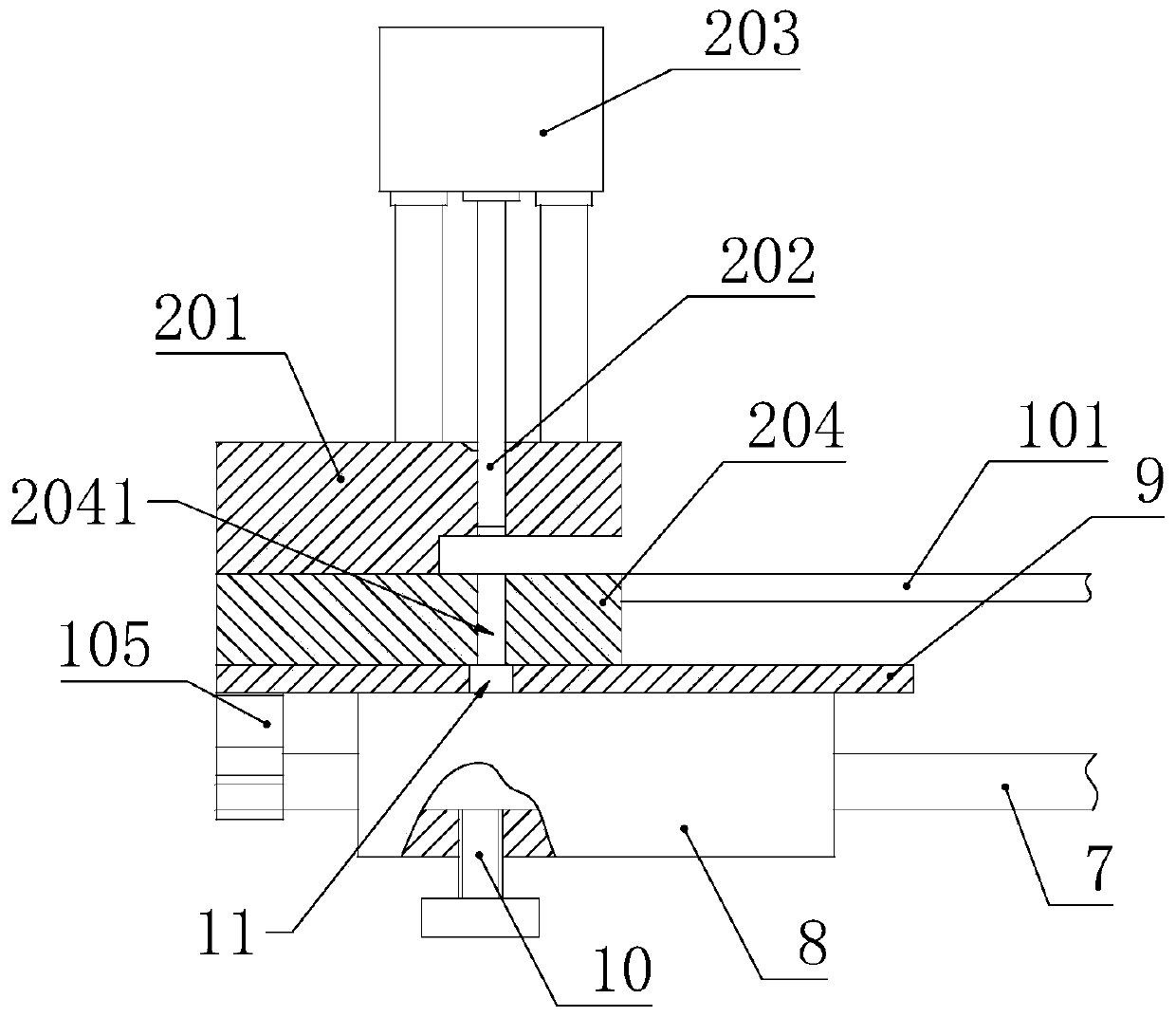

[0040] combine figure 1 and figure 2 As shown, the marking mechanism 2 includes a punch frame 201 arranged on one side of the feeding platform 1, a punch 202, a driving device 203 for driving the punch 202 to punch materials, and a 1, the stamping die 204 matched with the punch 202, the driving device 203 is an air cylinder, fixedly connected on the punch frame 201, and the punch 202 is connected with the driving device 203 through transmission. In this embodiment, the side of the cross-section of the punch 202 close to the ma...

Embodiment 2

[0059] A method for controlling the feed rate of a die-cutting machine, comprising the following specific steps:

[0060] a. If Figure 8 As shown, a fixed position is set on the feeding platform 1 upstream of the molding system 4, and a marking mechanism 2 is installed to punch out marks on the material;

[0061] b. Set a fixed detection position between the molding system 4 and the marking mechanism 2 according to the material feeding distance requirements, and install the standard detection mechanism 3 to detect the marks on the material;

[0062] c. Control the feed of materials according to the detection results. When the mark detection mechanism 3 at the detection position detects the mark, stop the material feed, indicating that the feed amount reaches the requirement of the material feed distance, and the mark detection mechanism 3 at the detection position detects the mark. The mark is used as the basis, and the material is punched; while the material is punched, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com