Tobacco leaf subdividing device

A technology of tobacco leaf and air outlet device, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of inability to achieve large-scale application, inability to meet industrialization and process production, etc., and achieves an increase in output value and average price, fast classification speed, The effect of solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

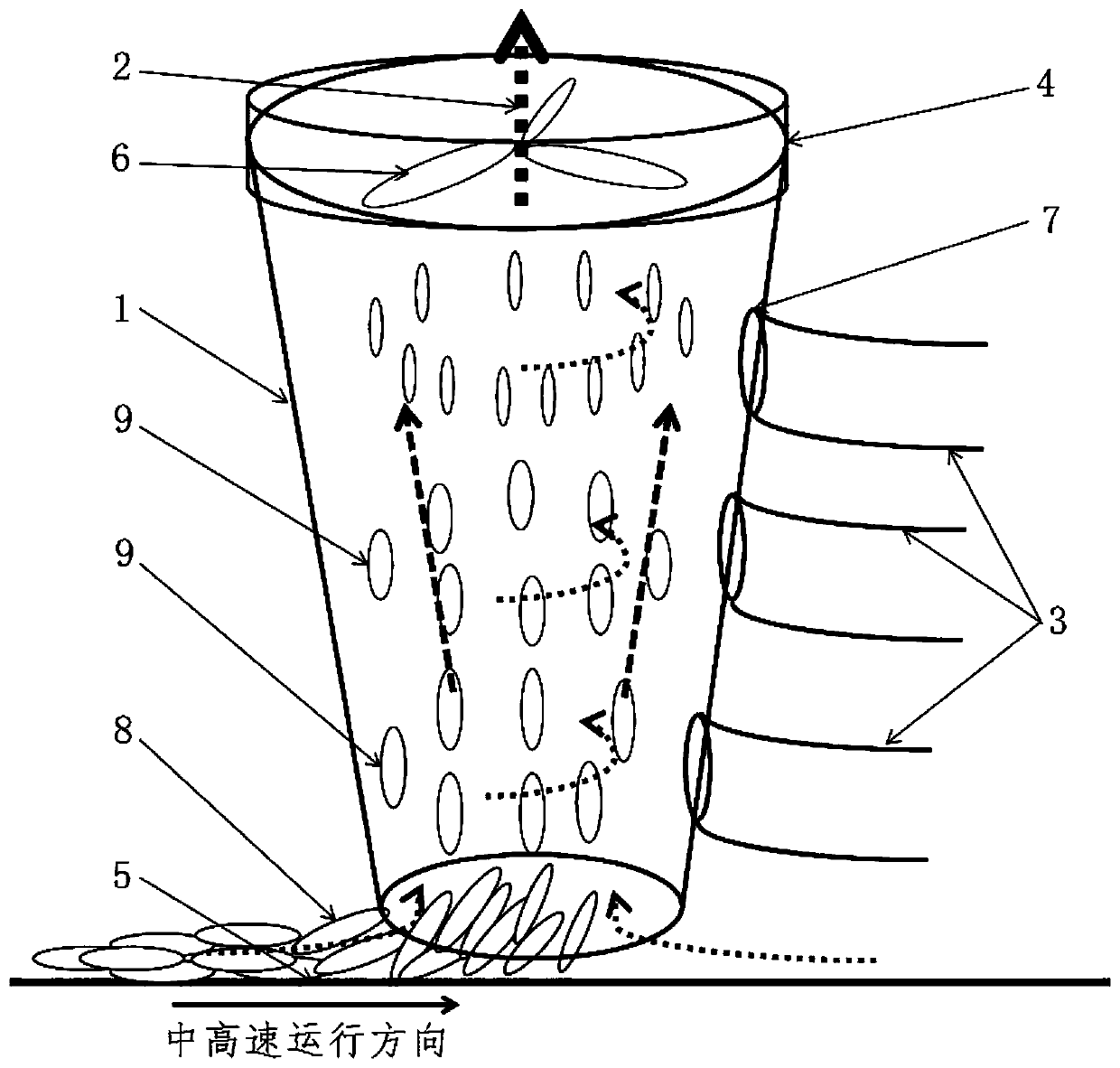

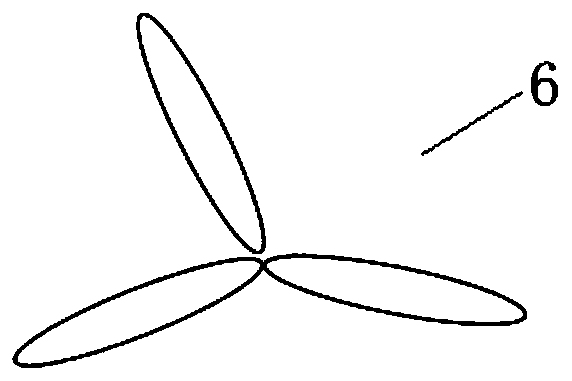

[0032] Such as figure 1 As shown, this embodiment provides a tobacco subdividing device, including a conical bucket 1 that is used to be inverted above the batch flow blades; the bottom of the conical bucket 1 is open for inhaling scattered tobacco leaves 8, and the The wind device is used to form a spiral wind direction in the barrel, the top is provided with an adjustable air outlet 2, and the side wall is provided with a plurality of tobacco leaf discharge pipes 3 along the axial direction of the barrel.

[0033] In this example, if figure 1 As shown, the small end of the conical barrel 1 is set downwards, and the large end is provided with a sealing cover 4, preferably the sealing cover 4 is threaded with the conical barrel 1; the adjustable air outlet 2 is preferably arranged at the center of the sealing cover 4.

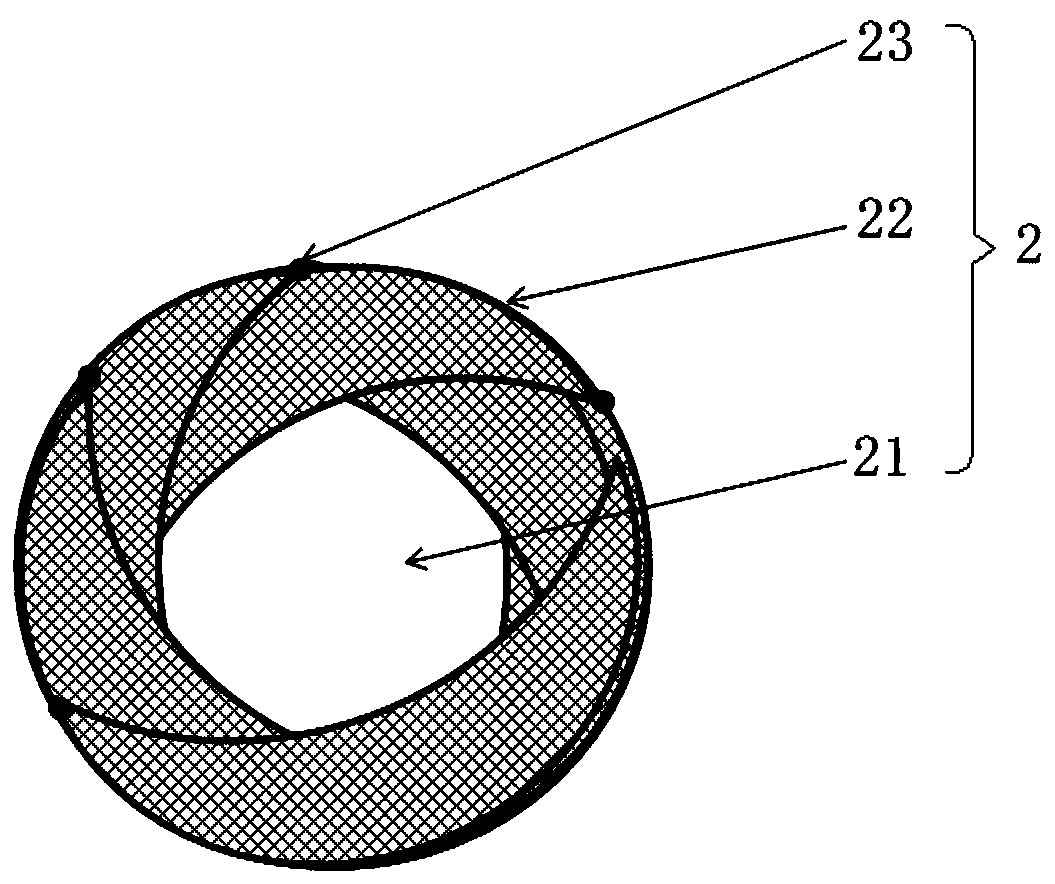

[0034] In this example, if figure 1 and 3 As shown, the adjustable air outlet 2 includes an air outlet 21 and a plurality of adjusting pieces 22, and severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com