All-electric roll changing system of cold rolling mill and roll changing method utilizing same

An all-electric, cold rolling mill technology, applied in rolling mill control devices, metal rolling stands, metal rolling mill stands, etc., can solve problems such as polluting the surface of the rolls and low automation of the roll changing system of the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

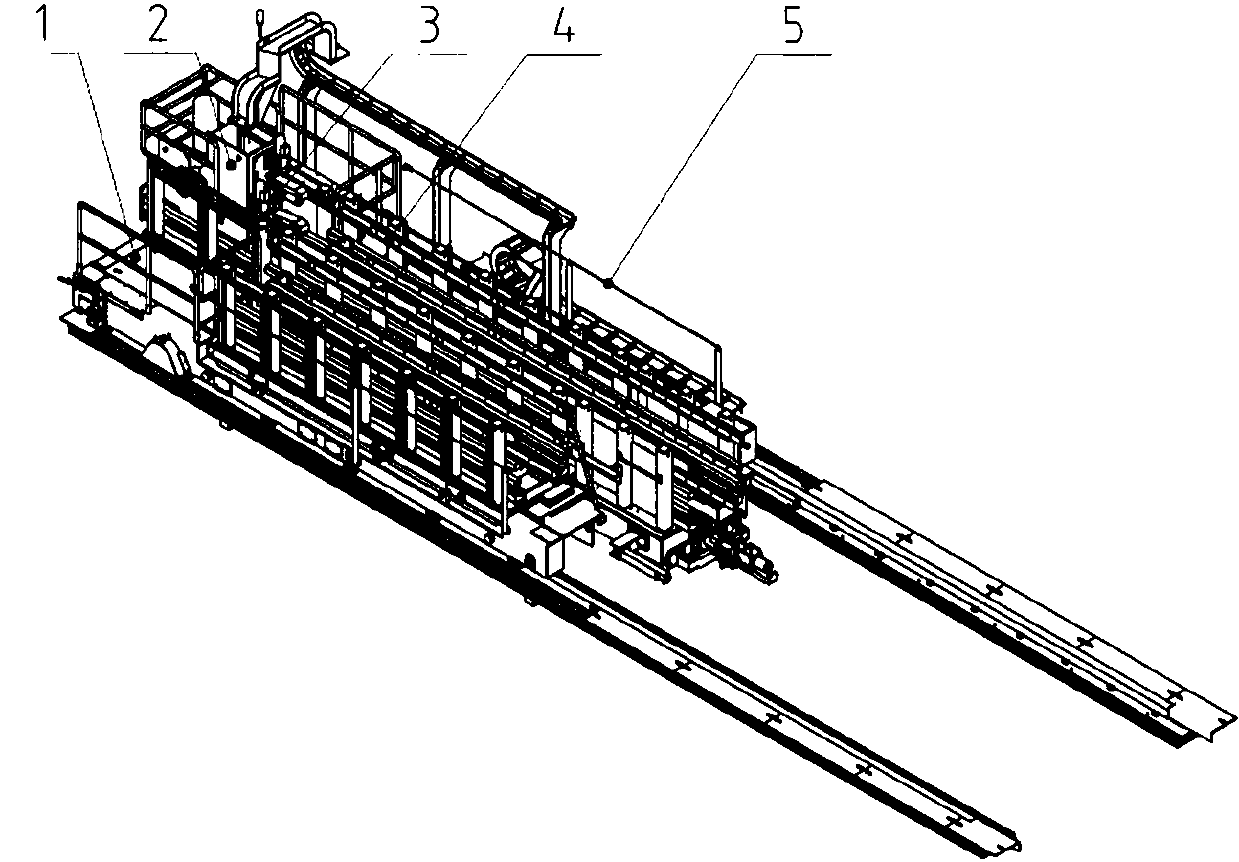

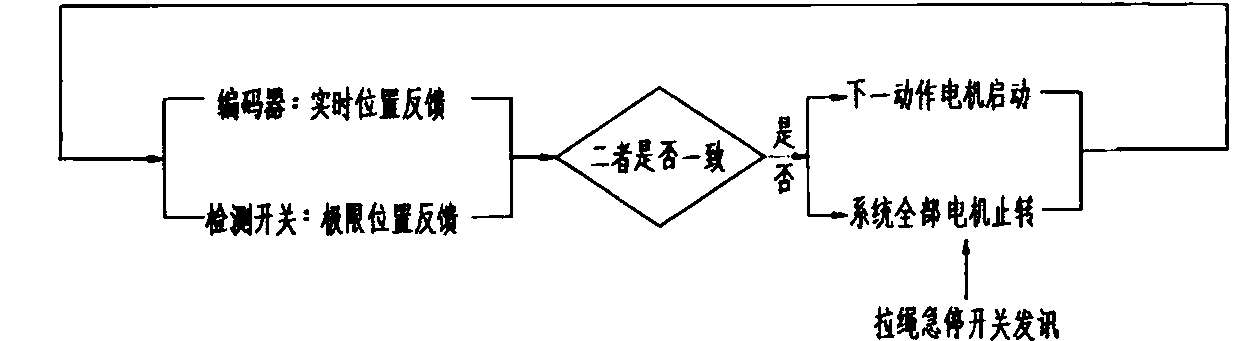

[0045] The first embodiment of the present invention relates to an all-electric roll changing system for a cold rolling mill, see figure 1 , including a trolley 1, a tractor 2, a traverse vehicle 4 and a pull rope emergency stop switch 5 are installed on the trolley 1, and the tractor 2 is connected with a clamping device 3, wherein the trolley 1, the tractor 2, the clamping Both the device 3 and the traverse car 4 have independent driving sources, the driving source is a motor, and an encoder is installed at the end of each motor, and several position switches are arranged in the roll changing area of the cold rolling mill, which are connected to the traveling car 1 respectively. The position switch corresponding to the limit position of the roll change area, the position switch corresponding to the limit position of the tractor 2 in the roll change area, the position switch corresponding to the limit position of the traverse vehicle 4 in the roll change area, and installed ...

no. 2 approach

[0057] This embodiment relates to the all-electric roll changing system of the cold rolling mill, see figure 1 , including a trolley 1, a tractor 2, a traverse vehicle 4 and a pull rope emergency stop switch 5 are installed on the trolley 1, and the tractor 2 is connected with a clamping device 3, wherein the trolley 1, the tractor 2, the clamping Both the device 3 and the traverse car 4 have independent driving sources, the driving source is a motor, and an encoder is installed at the end of each motor, and several position switches are arranged in the roll changing area of the cold rolling mill, which are connected to the traveling car 1 respectively. The position switch corresponding to the limit position of the roll change area, the position switch corresponding to the limit position of the tractor 2 in the roll change area, the position switch corresponding to the limit position of the traverse vehicle 4 in the roll change area, and installed on The position switch of t...

no. 3 approach

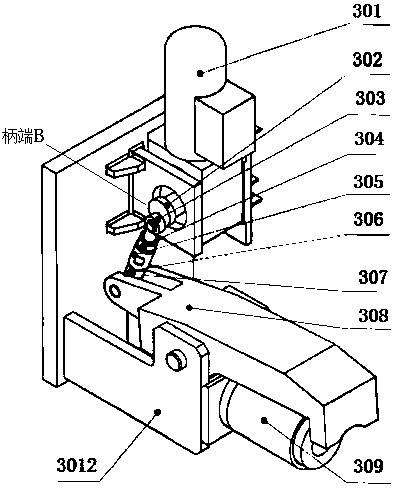

[0073] This embodiment relates to the all-electric roll changing system of the cold rolling mill, see image 3 , including a trolley 1, a tractor 2, a traverse vehicle 4 and a pull rope emergency stop switch 5 are installed on the trolley 1, and the tractor 2 is connected with a clamping device 3, wherein the trolley 1, the tractor 2, the clamping Both the device 3 and the traverse car 4 have independent driving sources, the driving source is a motor, and an encoder is installed at the end of each motor, and several position switches are arranged in the roll changing area of the cold rolling mill, which are connected to the traveling car 1 respectively. The position switch corresponding to the limit position of the roll change area, the position switch corresponding to the limit position of the tractor 2 in the roll change area, the position switch corresponding to the limit position of the traverse vehicle 4 in the roll change area, and installed on The position switch of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com