Prediction method of mold breakout based on image processing

An image processing and crystallizer technology, applied in the field of continuous casting technology, can solve problems such as low accuracy of breakout prediction, high data requirements, and algorithm limitations, so as to reduce the rate of false alarms, reduce data dependence, and overcome leaks. The effect of positive rate and false positive rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

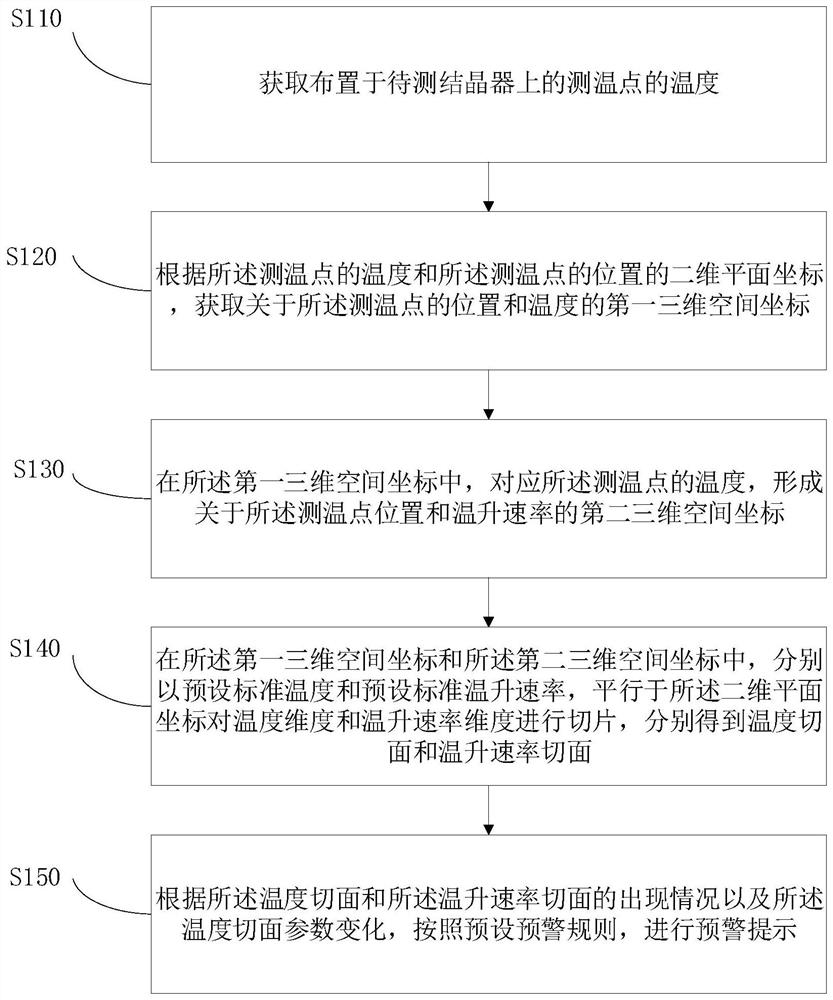

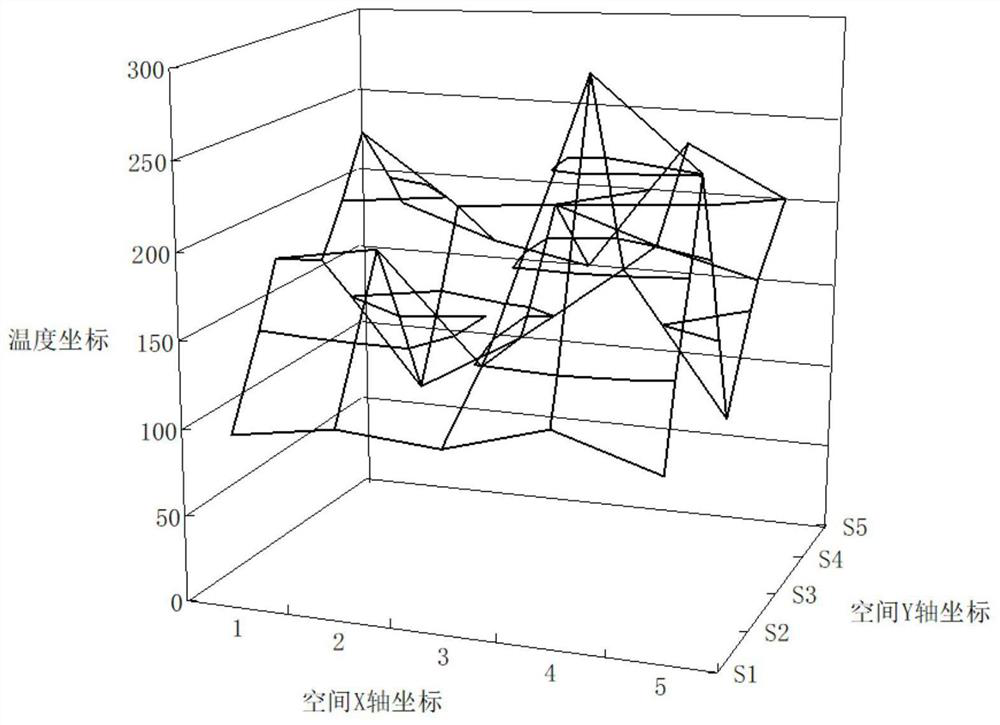

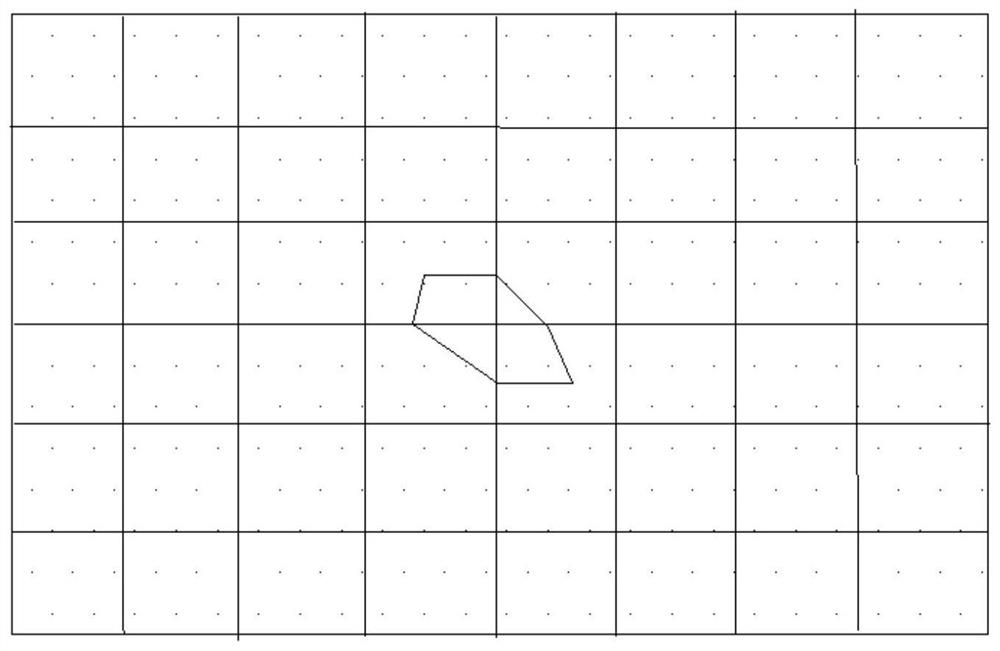

Method used

Image

Examples

Embodiment Construction

[0049] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

[0050] Aiming at the bottleneck of the breakout prediction algorithm in the existing method proposed above in terms of false alarm rate and false alarm rate, and the algorithm itself has too high requirements for data, it is easy to omit information, which leads to the limitation of the algorithm. Thereby lead to problems such as low accuracy of breakout prediction, the present invention proposes a kind of crystallizer breakout prediction method based on image processing for above-mentioned problems, adopts the method of the present invention to be able to overcome the rate of false alarm and the The contradiction of the false positive rate will not increase the false negative rate while reducing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com