Pressure vessel flange and its processing method

A technology for pressure vessels and flanges, applied in the field of pressure vessel flanges and their processing, can solve problems such as threats to the safety of the pressure vessel body and surrounding equipment personnel, secondary disasters, flammability, etc., and achieve excellent waterproof and sealing effects. Strong focus and the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

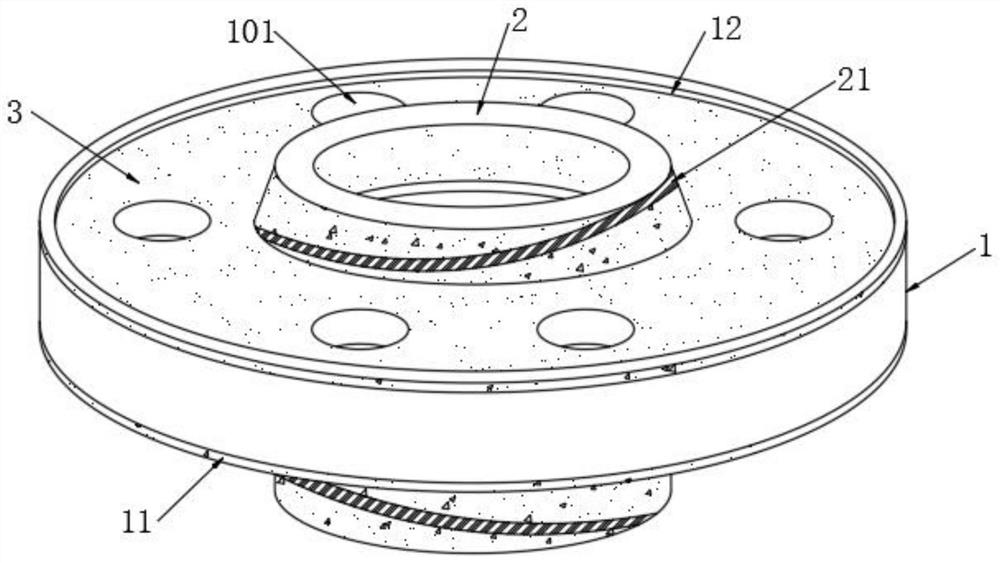

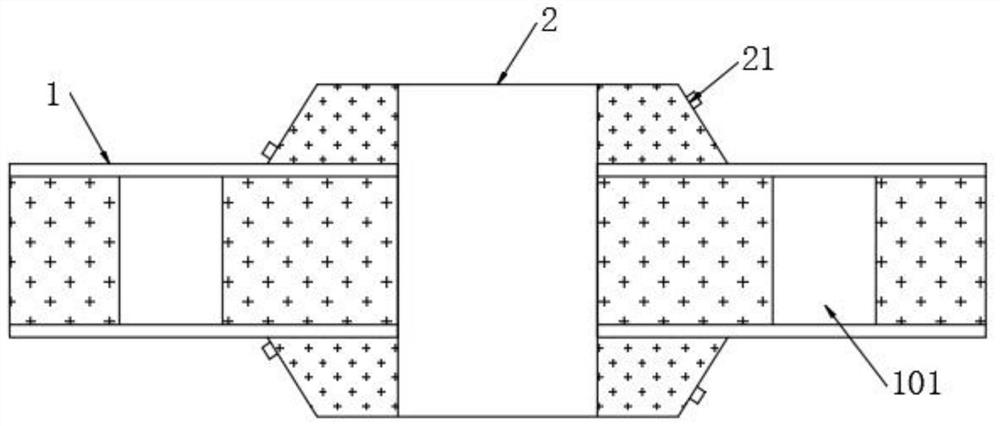

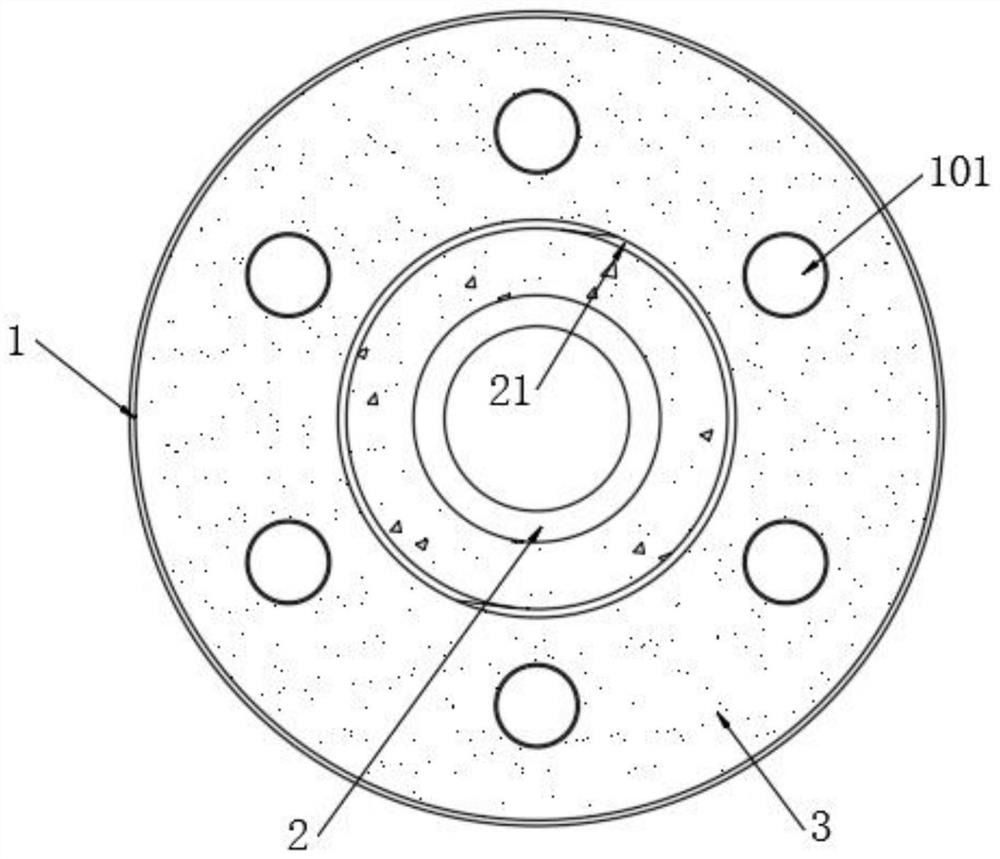

[0032] See Figure 1-3 The present invention provides the following technical solution: the pressure vessel flange, including the flange plate 1, the flange plate 1 has a plurality of screw holes 101 in the center symmetric distribution, the intermediate position of the flange 1 and the bottom intermediate position The connection bearing 2 having a symmetric distribution is provided, and the outer wall of the connecting shaft 2 has a threaded projection 21 having a helical distribution, and the upper and lower ends of the flange plate 1 have a protruding flange 1. Limit groove 12, the limit groove 12 has a groove between the flange 1.

[0033] In the present embodiment: the outer wall of the connecting shaft column 2 has a threaded projection 21 having a helical distribution, and the upper and lower ends of the flange plate 1 are fixed, and the limit groove 12, limited to the flange 1. The bit groove 12 has a groove between the flange plates 1; using the threaded projection 21 to i...

Embodiment 2

[0050] See Figure 1-3 The present invention provides the following technical solution: the pressure vessel flange, including the flange plate 1, the flange plate 1 has a plurality of screw holes 101 in the center symmetric distribution, the intermediate position of the flange 1 and the bottom intermediate position The connection bearing 2 having a symmetric distribution is provided, and the outer wall of the connecting shaft 2 has a threaded projection 21 having a helical distribution, and the upper and lower ends of the flange plate 1 have a protruding flange 1. Limit groove 12, the limit groove 12 has a groove between the flange 1.

[0051] In the present embodiment: the outer wall of the connecting shaft column 2 has a threaded projection 21 having a helical distribution, and the upper and lower ends of the flange plate 1 are fixed, and the limit groove 12, limited to the flange 1. The bit groove 12 has a groove between the flange plates 1; using the threaded projection 21 to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com