A device for measuring and adjusting thrust clearance of angular contact ball bearings

A technology of angular contact ball bearing and adjustment device, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of inaccurate measurement, complicated and laborious measurement and adjustment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

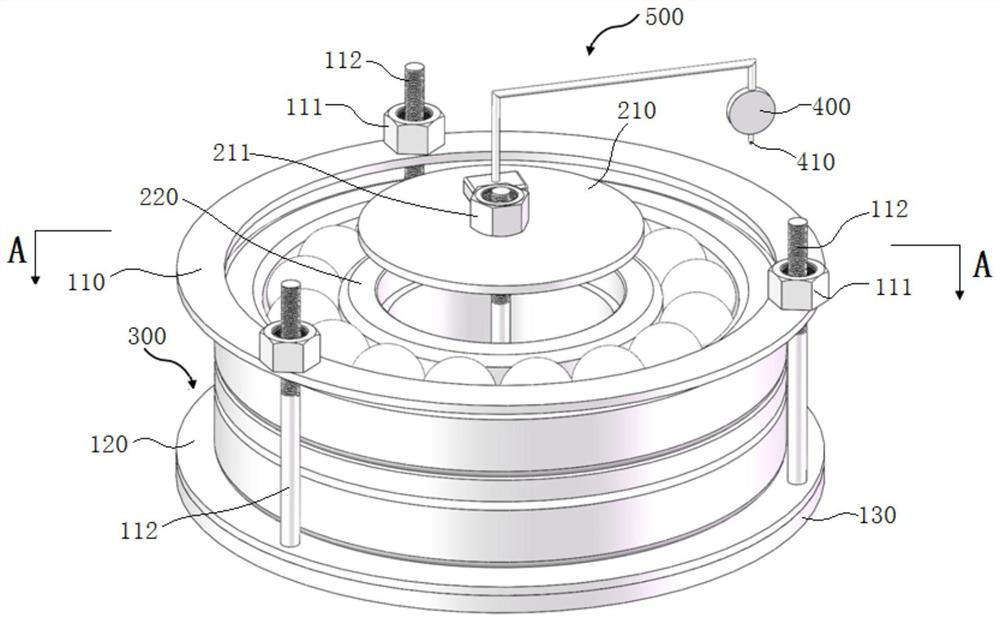

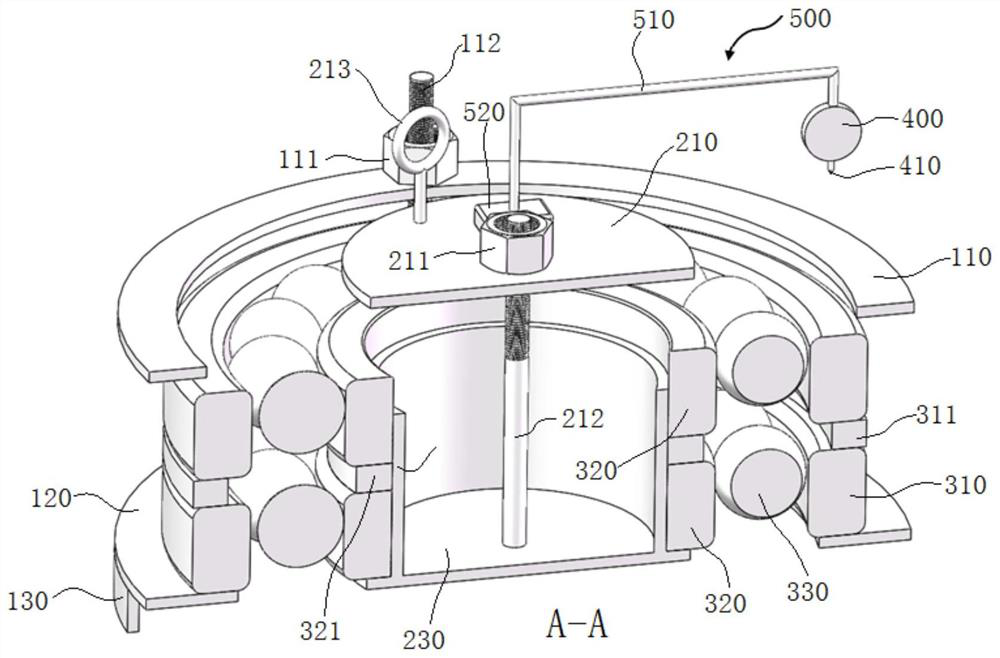

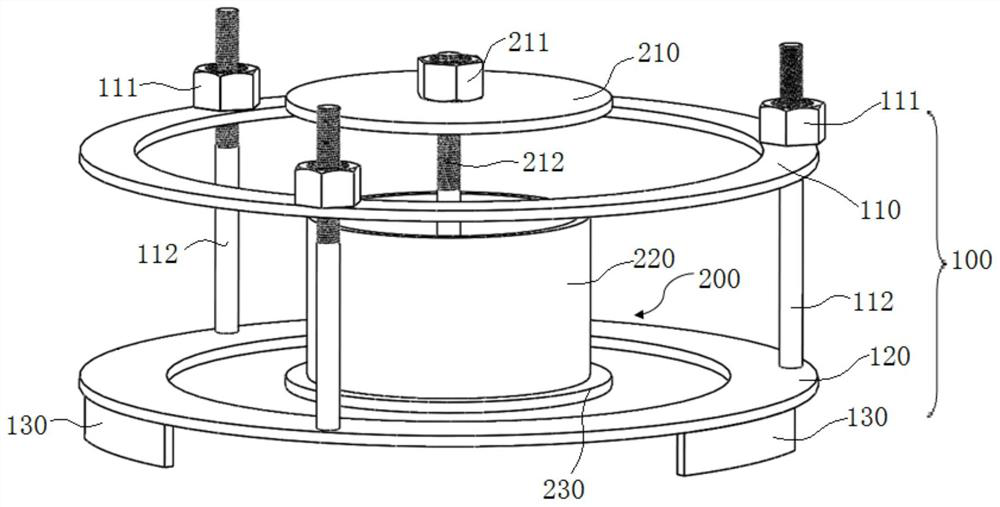

[0037] combine figure 1 and figure 2 As shown, the angular contact ball bearing 300 includes a bearing inner ring 320 and a bearing outer ring 310 arranged from inside to outside, and the bearing inner ring 320 and the bearing outer ring 310 are connected by steel balls 330 . Among them, the bearings used to balance the axial thrust are mostly angular contact ball bearings 300 installed in pairs. An inner spacer 321 and an outer spacer 311 are installed between the two angular contact ball bearings 300, that is, two angular contact ball bearings installed in pairs. An inner spacer 321 is installed between the bearing inner rings 320 of the ball bearing 300, and an outer spacer 311 is installed between the bearing outer rings 310 of the two angular contact ball bearings 300, and the outer spacer 311 needs to be measured and adjusted during assembly. , so that the total thrust clearance of the bearing set reaches a qualified range. The traditional assembly sequence of the ang...

Embodiment 2

[0045] The thrust gap measuring and adjusting device of a set of angular contact ball bearings in this implementation has basically the same structure as that of Embodiment 1, further, as figure 2 As shown, the fixing unit 500 in this embodiment includes a fixing base 520 fixed on the top of the inner ring pressure plate 210 and a fixing rod 510 , one end of the fixing rod 510 is connected with the fixing base 520 , and the other end of the fixing rod 510 is connected with the dial indicator 400 . The fixed rod 510 includes a fixed section arranged on the top of the fixed base 520 , wherein the top of the fixed section extends outwards to provide a support section, and the bottom of the support section extends downwards to provide a connecting section, and the bottom of the connecting section is connected to the dial indicator 400 .

[0046] In this embodiment, a detachable connection is adopted between the fixed base 520 and the inner ring pressure plate 210. Specifically, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com