Injection-molded flange gasket groove-spinning external-broaching device

A flange pad and mounting plate technology, applied in metal processing and other directions, can solve the problems of low production efficiency, easy to get hurt, unable to meet the factory production volume, etc., to achieve the effect of increasing production volume and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

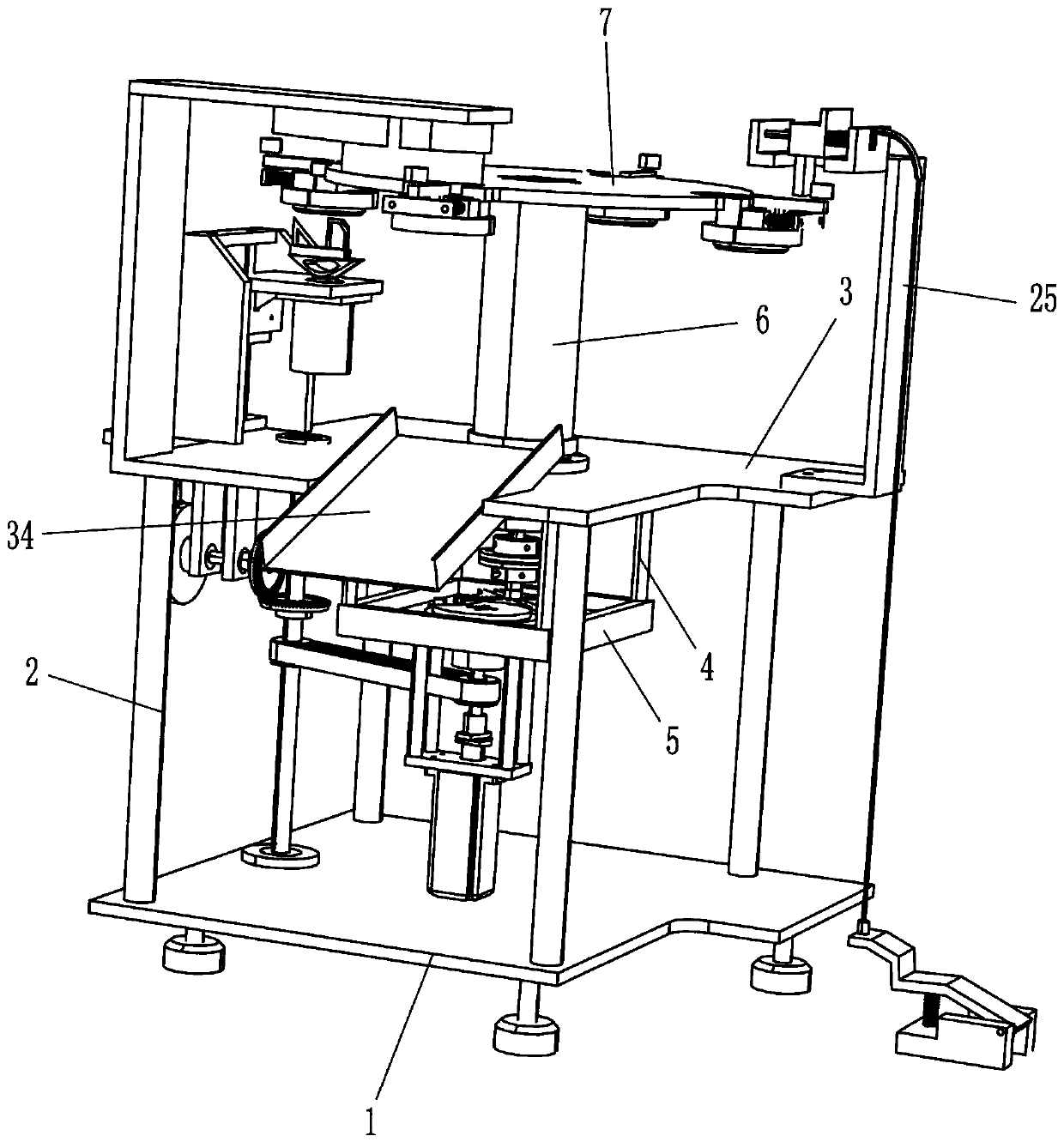

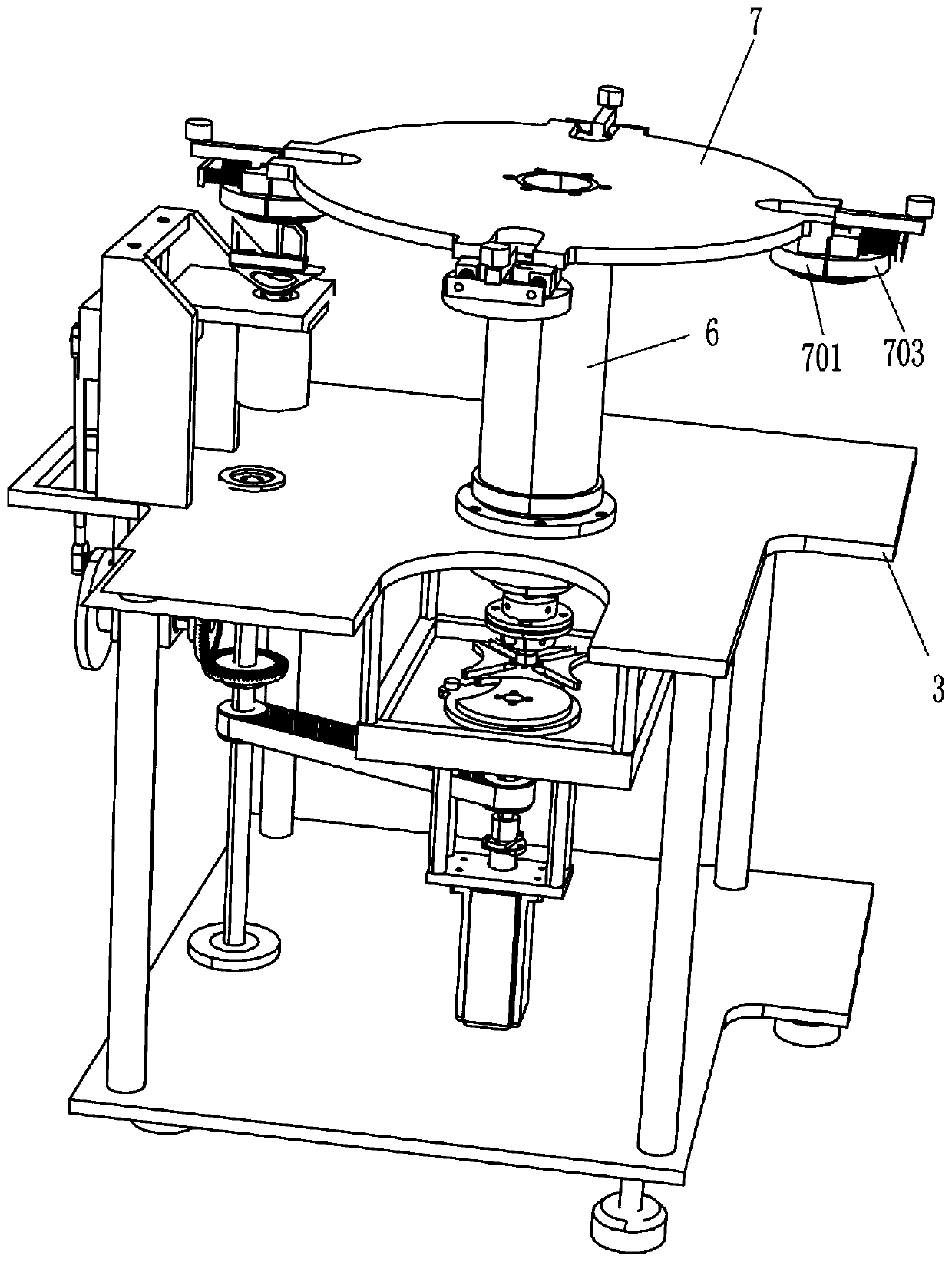

[0077] An injection molding flange gasket rotary groove external cutting device, such as figure 1As shown, it includes a lower bracket 1, a support rod 2, an upper bracket 3, a support rod 2 4, a mounting plate 5, an intermittent mechanism, a drum 6, a turntable 7, a material clamping mechanism and a rotary groove mechanism, and the support rod One 2 is four, fixed on the top of the lower bracket 1, the upper bracket 3 is fixed on the top of the support rod one 2, and the support rod two 4 is four, fixed on the bottom of the upper bracket 3, the mounting plate One 5 is fixedly connected under the support rod two 4, the intermittent mechanism is fixed on the middle part of the lower bracket 1, the upper part of the intermittent mechanism is installed in the installation plate one 5, and the drum 6 is fixedly connected to the intermittent mechanism, which is located on the upper bracket 3 In the middle part, the turntable 7 is affixed to the top of the drum 6, and there are four...

Embodiment 2

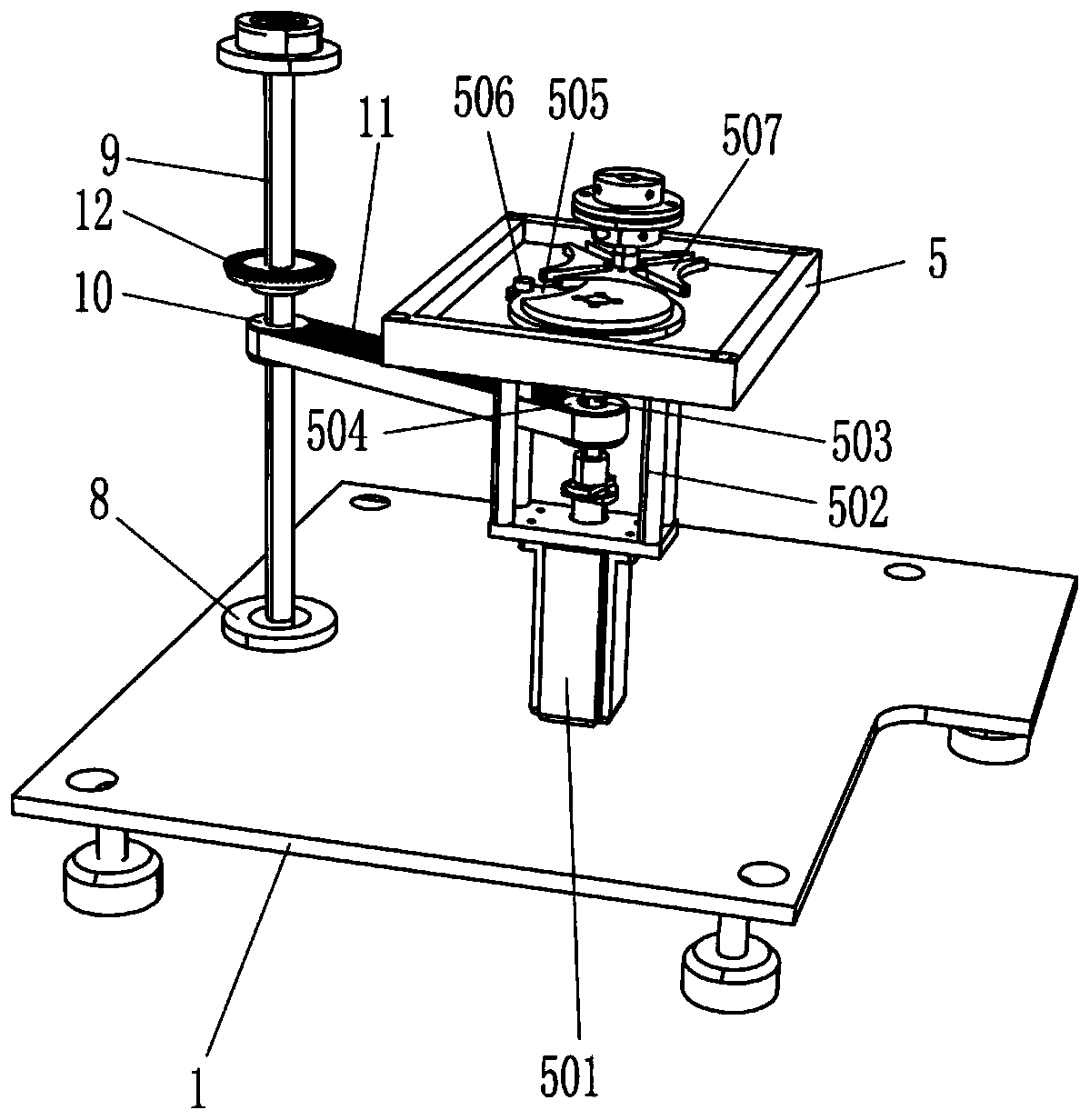

[0080] On the basis of embodiment 1, a kind of injection molding flange gasket rotary groove external cutting device, such as Figure 1-6 As shown, the intermittent mechanism includes a servo motor 501, a mounting frame 502, a connecting shaft 503, a pulley 504, a cam disc 505, a toggle column 506 and a square grooved disc 507, and the servo motor 501 is fixedly connected to the middle of the lower bracket 1 , the mounting bracket 502 is fixedly connected to the servo motor 501, the connecting shaft 503 is fixedly connected to the output shaft of the servo motor 501 through a coupling, passes through the mounting plate 5, and the pulley 504 is fixedly connected to the connecting shaft 503, located on the mounting plate 5 Below, the cam disc 505 is fixedly connected to the top of the connecting shaft 503 and is located in the mounting plate 5, the toggle column 506 is fixedly connected to the cam disc 505, and the four-corner grooved disc 507 is rotatably connected to the mounti...

Embodiment 3

[0087] On the basis of embodiment 2, a kind of injection molding flange gasket rotary groove external cutting device, such as Figure 7 As shown, it also includes a discharge assembly, which includes:

[0088] Also includes a discharge assembly, the discharge assembly includes a fixed plate 23 and a curved plate 24, the fixed plate 23 is fixed on the left side of the upper bracket 3, located in front of the rotary groove mechanism, and the curved plate 24 is fixed on the fixed Below the second plate 23 , the arc plate 24 is in contact with the roller 707 .

[0089] When the roller 707 was in contact with the protruding part of the arc plate 24, the roller 707 moved to the right to drive the connecting rod 706 to move to the right, and the connecting rod 706 moved to the right to drive the movable chuck 703 to move to the right through the slide bar one 702, so that the rotary The flange gasket cut outside the groove automatically falls down, thus replacing the function of man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com