Ink-free number printing device for storage battery

A storage battery and ink technology, applied in decorative arts, embossed ornaments, etc., can solve problems that cannot be traced back to employee responsibilities, ink marks are easy to wear off, and the environment is polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

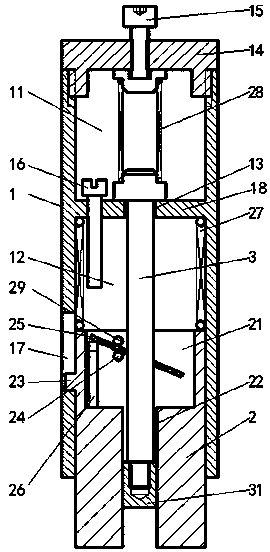

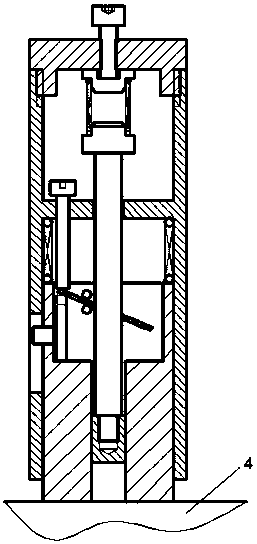

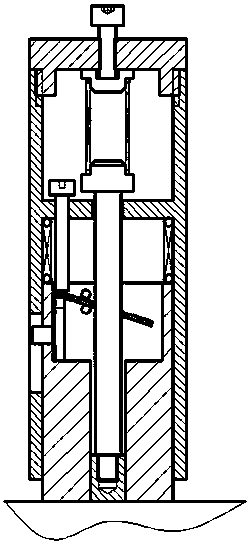

[0022] This embodiment provides an inkless marking device for batteries, such as figure 1 , mainly consists of a grip 1, a reset block 2, a punch 3 and a pull-up mechanism for the punch, the upper part of the reset block 2 is provided with a reset block groove 21, and the pull-up mechanism for the punch is arranged in the reset block groove 21; The interior is hollow, and is divided into an upper shallow sinker 11 and a lower deep sinker 12 by a partition 18. The upper end of the punch 3 penetrates the first through hole 13 of the partition 18 and is located in the shallow sinker 11, and passes through the rebound spring 28 It is connected to the top cover 14 of the grip 1, the lower part is located in the deep groove 12 and its bottom punch 31 is adapted to the second through hole 22 of the reset block 2, the font on the bottom surface of the punch 31 is protruding, and the font thickness h is 0.4- 1.5mm, forming an included angle θ of 30-90°; the reset block 1 is connected t...

Embodiment approach 2

[0029] This embodiment is a further improvement of Embodiment 1. The main improvement is that, in Embodiment 1, the depth of the number punched out on the surface of the battery 4 is constant; The upper thread is connected with the adjusting bolt 15, the adjusting bolt 15 is coaxially arranged with the grip sleeve 1, the bottom end of the adjusting bolt 15 penetrates the top cover 14 and is fixedly connected with the top of the rebound spring 28, and the adjusting bolt 15 is connected with the punch rod 3 and the rebound spring 28. The spring 28 is also arranged coaxially.

[0030] When it is necessary to adjust the depth of the work numbers punched out on the surface of the battery 4 deeper, the adjusting bolt 15 is adjusted downward, and the rebound spring 28 will be compressed shorter, and the rebound force of the punch rod 3 will be larger, and the printed work numbers will be larger. No. depth is deeper, and vice versa.

[0031]Apart from this, this embodiment is complet...

Embodiment approach 3

[0033] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, when the reset block 2 is pressed, the reset block 2 may rotate in the deep sinker 12, which will affect the upper position of the punch. The pull-up effect of the pull mechanism on the punch rod 3, and in the present embodiment, a limit pin 23 is provided on one side of the reset block 2, and a limit groove 17 in a vertical direction is provided on the side wall of the relative position of the deep sinker 12. When the reset block 2 moved up, the drive stop pin 23 could only move up and down in the stop slot 17, which effectively prevented the reset block 2 from rotating, and ensured the pull-up effect of the punch rod pull-up mechanism on the punch rod 3.

[0034] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com