Troubleshooting device for high-altitude cable maintenance

A high-altitude cable and barrier-removing rod technology, which is used in overhead lines/cable equipment, transportation and packaging, motor vehicles, etc., can solve problems such as low efficiency and labor consumption, and achieve high work quality, reduced production costs, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

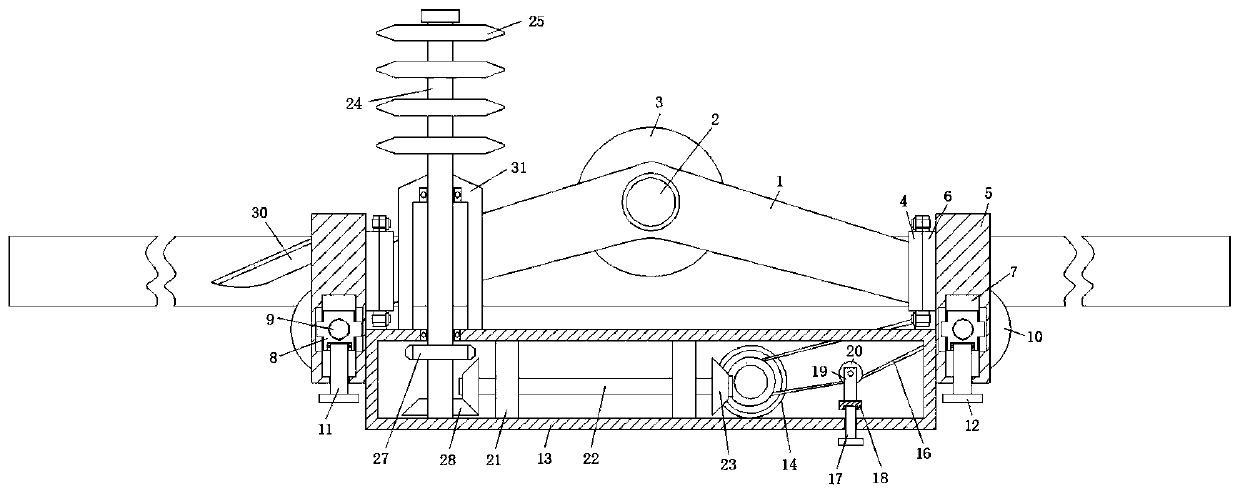

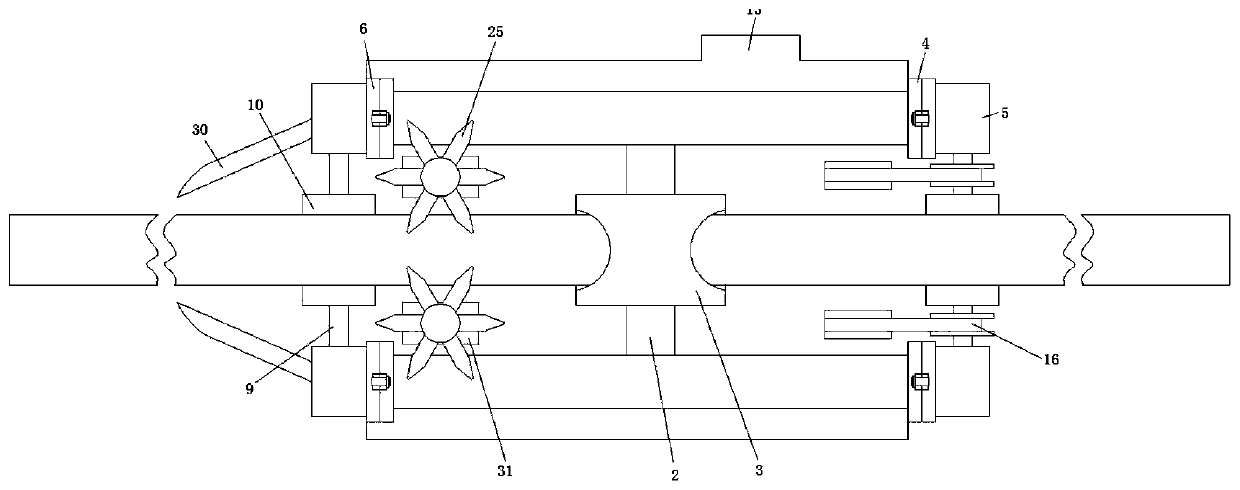

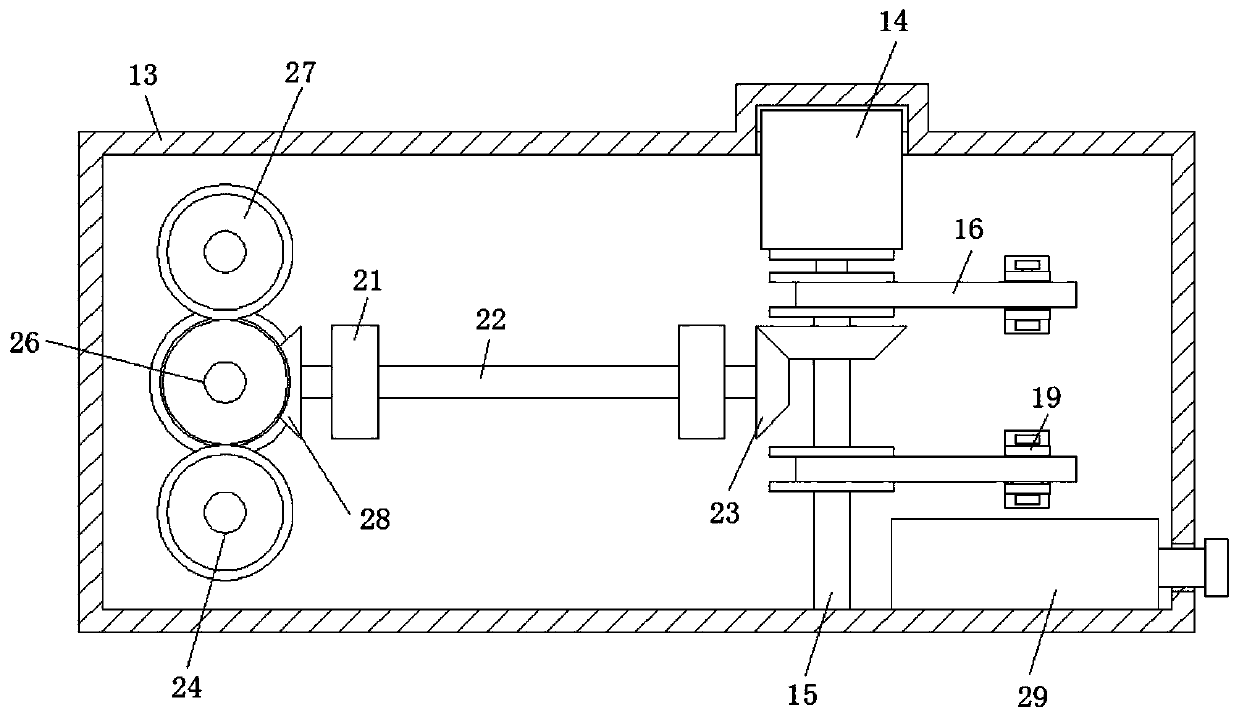

[0028] refer to Figure 1-4 , a kind of troubleshooting device for high-altitude cable maintenance, including V-shaped rods 1, two V-shaped rods 1 are provided with openings facing downwards, the middle parts of the two V-shaped rods 1 are connected with suspension rods 2 in rotation, and the suspension rods 2 The outer wall of the rod is fixedly connected with a suspension wheel 3 by screws, the end faces of both sides of the V-shaped rod 1 are fixedly connected with a connecting plate 4, and both sides of the V-shaped rod 1 are provided with a mounting strip 5, and the mounting strip 5 is located near the end of the V-shaped rod 1. The two sides are fixedly connected with the connecting plate 2 6, and the connecting plate 2 6 and the connecting plate 1 4 are fixedly connected by screws. The lower end of the mounting bar 5 is also provided with a mounting groove 7 through the front and rear sides, and the mounting groove 7 is slidingly connected with a mounting block 8. A mou...

Embodiment 2

[0031] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the end of the installation strip 5 on the side close to the removal bar 24 away from the V-shaped bar 1 is fixedly connected with a removal knife 30, and the removal knife 30 is provided by the installation box. The inboard of body 13 outer sides is inclined downwards.

[0032] In this embodiment, the installation bar 5 on one side of the obstacle removal rod 24 is fixedly connected with an obstacle removal knife 30 at the end away from the V-shaped bar 1, so as to pick up and cut off the sundries hanging on the cable, thereby improving the quality of the cable obstacle removal work. higher.

Embodiment 3

[0034] Such as figure 1 and 2As shown, this embodiment is basically the same as Embodiment 1. Preferably, the front and rear ends of the top surface of the installation box 13 close to the barrier rod 24 are also fixedly connected with a stabilizing frame 31, and the stabilizing frame 31 is arranged in a "U" shape, and The obstacle removal bar 24 is rotationally connected with the stabilizing frame 31 through rolling bearings.

[0035] In this embodiment, a stabilizing frame 31 is added on the top surface of the installation box 13, and the obstacle removing rod 24 is rotationally connected with the stabilizing frame 31 through a rolling bearing, so that the rotation of the obstacle removing rod 24 is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com