Automatic cover pressing and screwing device for gift packaging tins

An automatic technology for packaging cans, which is applied in the field of automatic gland screwing devices for gift packaging cans, which can solve the problems of broken gift cans on the ground, loss, broken gift cans, etc., and achieve the effect of preventing human hands from being injured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

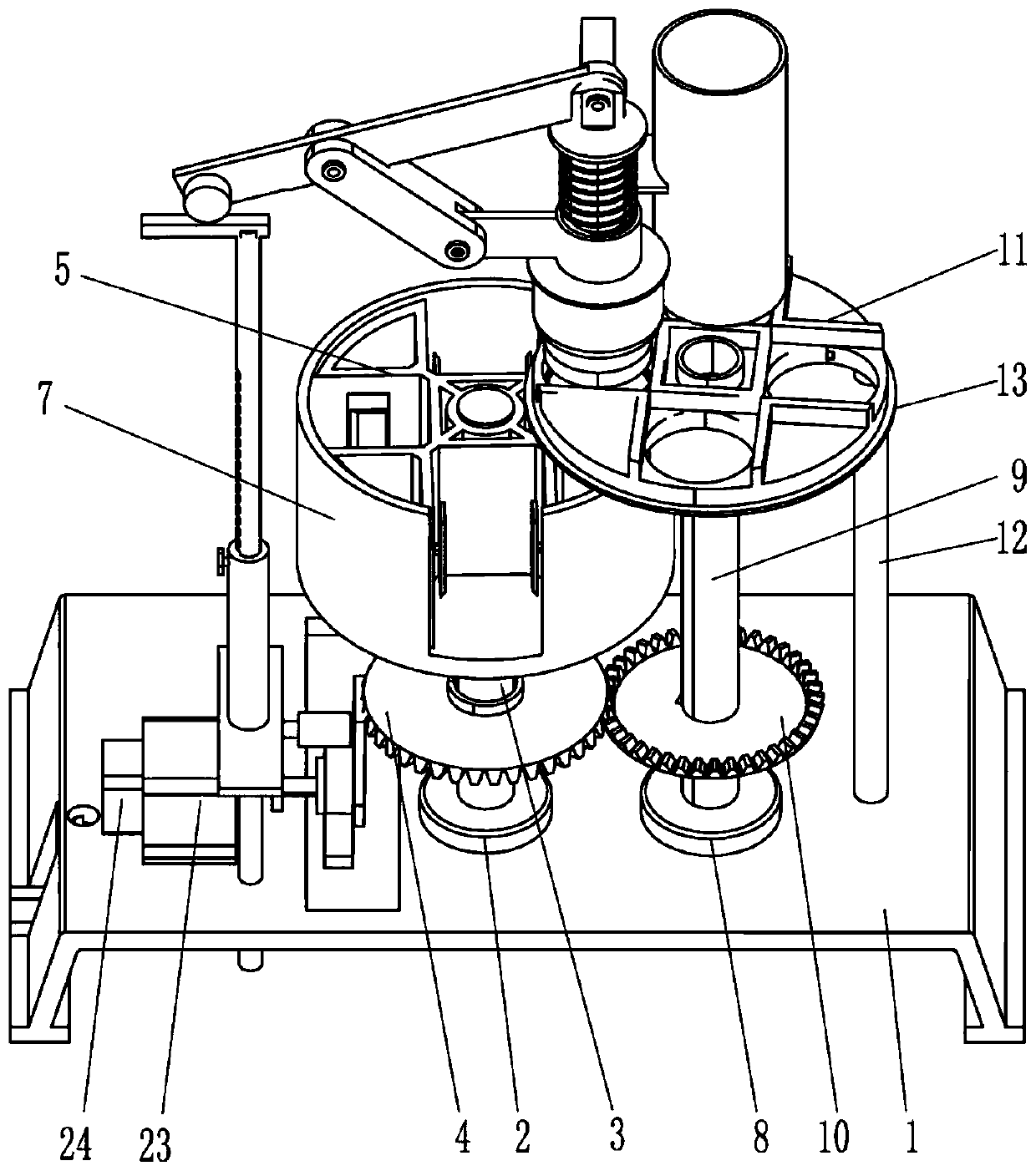

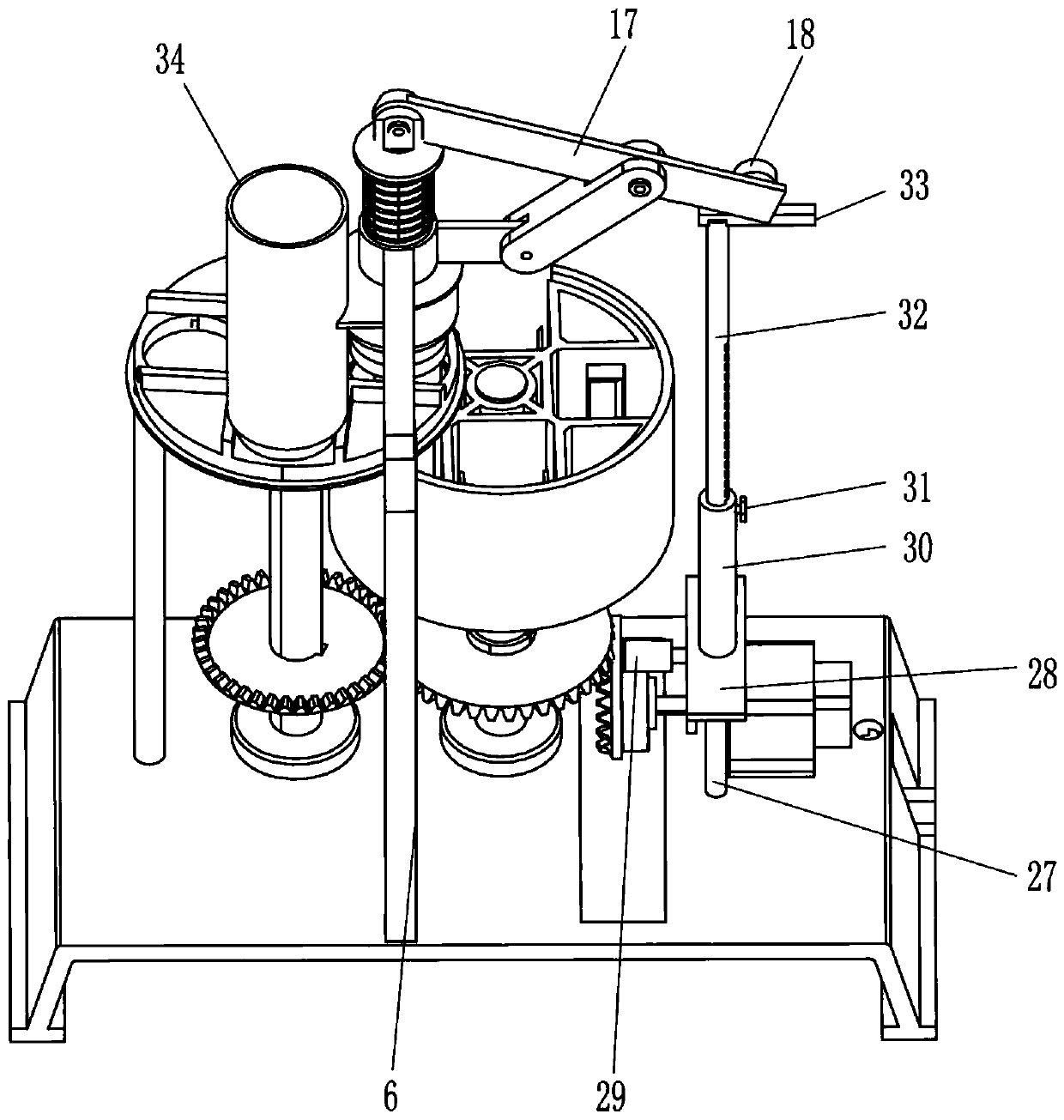

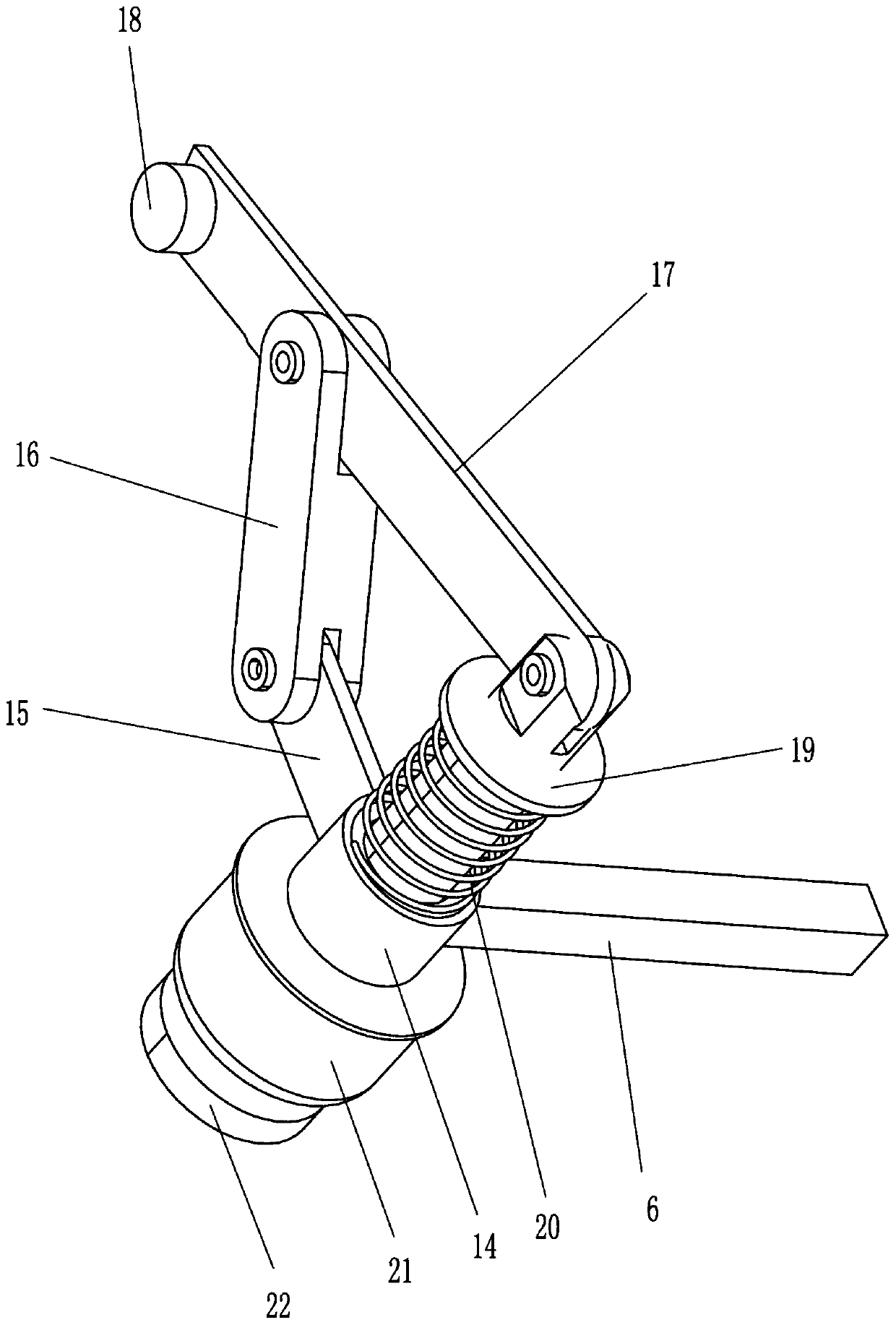

[0073] An automatic gland screwing device for gift packaging jars, such as Figure 1-8As shown, it includes organic seat 1, bearing seat 2, rotating shaft 3, bevel gear 1 4, limit turntable 5, telescopic clamping device, support frame 6, shell 7, bearing seat 2 8, rotating shaft 2 9, and gear 2 10. Material tray 11, telescopic stop rod device, support rod 12, hole plate 13, guide sleeve 14 and pressing device, bearing seat 12 is fixed on the top of machine base 1, rotating shaft 13 is connected to the top of bearing seat 2 by rotation, and the cone The gear one 4 is horizontally connected to the rotating shaft one 3 and is located above the bearing seat one 2. The limit dial 5 is sleeved on the end of the rotating shaft one 3 and fixedly connected with the rotating shaft one 3. The limit dial 5 is located above the bevel gear one 4 to limit the The position turntable 5 is provided with four slots, and four pairs of telescopic clamping devices are symmetrically installed in the...

Embodiment 2

[0076] On the basis of embodiment 1, a kind of automatic gland screwing device of gift packaging can, such as Figure 3-8 As shown, eight telescopic clamping devices are symmetrically arranged in the limit turntable 5, and the telescopic clamping devices include a hollow sleeve 501, an inner rod 503, a spring 502 and a splint 504, and the hollow sleeve 501 is symmetrically inserted into the limit In slot 5 of turntable, inner rod 1 503 is slidingly connected with hollow sleeve 1 501, spring 1 502 is installed in hollow sleeve 1 501, one end of spring 1 502 is fixedly connected to hollow sleeve 1 501, and the other end is fixedly connected to inner rod 1 The end of 503 and the splint 504 are fixedly connected to the other end of the inner rod one 503 respectively, and the splint 504 is symmetrically arranged on the two side walls of the slot of the limit turntable 5 .

[0077] When the gift jar is manually put into the slot 5 of the limit turntable through the 7 openings of the...

Embodiment 3

[0083] On the basis of embodiment 2, a kind of automatic gland screwing device of gift packaging can, such as Figure 1-4 As shown, a power mechanism is also included, and the power mechanism includes a mounting base 23, a second motor 24 and a sector bevel gear 25, the mounting base 23 is fixedly connected to the top of the machine base 1, and is located on the left side of the bearing seat 2, and the second motor 24 is fixedly connected On the top of the base 1, the second motor 24 is connected to the mounting base 23, the bevel sector gear 25 is fixedly connected to the right side of the output shaft of the second motor 24, and the bevel sector gear 25 meshes with the first bevel gear 4.

[0084] When capping the gift jar, start motor 2 24 to rotate, sector bevel gear 25 is 1 / 4 of bevel gear 1 4, motor 2 24 rotates to drive sector bevel gear 25 to rotate, sector bevel gear 25 meshes with bevel gear 1 4 Rotate, bevel gear one 4 and gear two 10 mesh and rotate, thereby make r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com