A kind of water-based self-polishing antifouling coating and its preparation method and application

An antifouling coating and self-polishing technology, applied in antifouling/underwater coatings, rosin coatings, coatings, etc., can solve problems such as not being suitable for long-term immersion use, poor water resistance of paint films, etc., and achieve good self-renewal ability and successful production Good film properties and ultra-low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

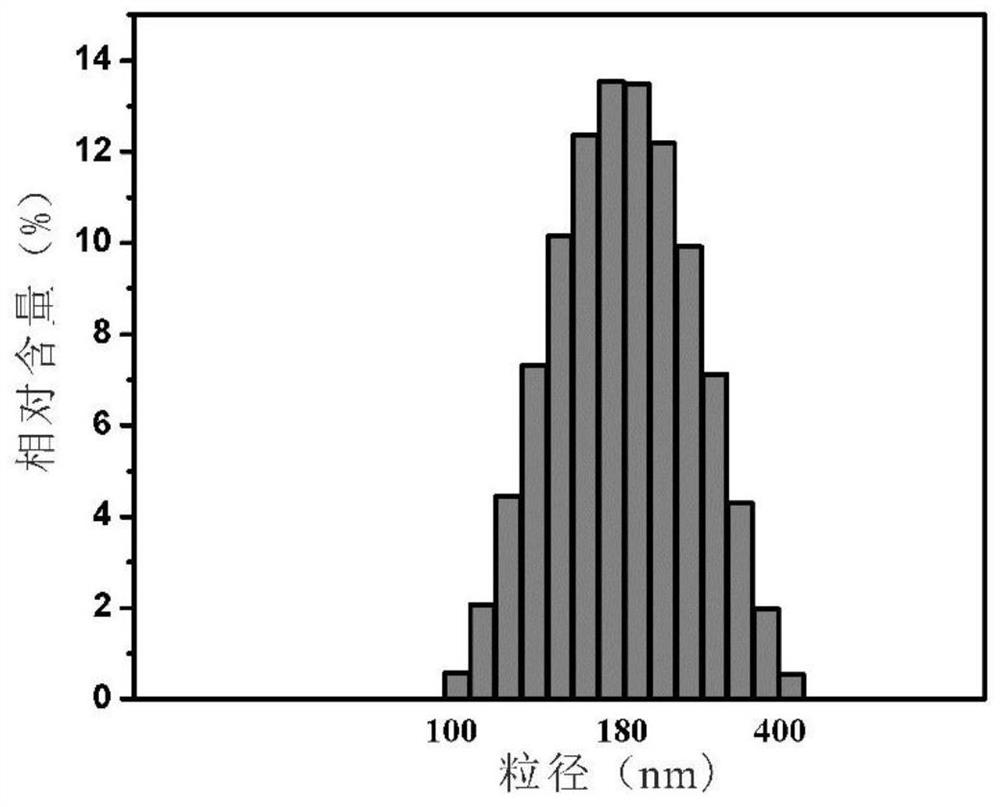

[0044] The preparation raw material of described aqueous slurry comprises antifouling agent, pigment and filler, organic bentonite, thickener, water-based wetting and dispersing agent and water, and described antifouling agent, pigment and filler, organic bentonite, thickener, aqueous wetting The mass ratio of the dispersant to water is (40-60): (5-10): (3-4): (0.5-1): (0.5-1): (30-40).

[0045] The water-based self-polishing antifouling coating provided by the present invention mainly uses water-based self-polishing emulsion and water-based slurry as raw materials for preparation, and the water-based self-polishing emulsion and water-based slurry are firstly described below.

[0046] In the present invention, the aqueous self-polishing emulsion includes the following preparation raw materials in mass percent:

[0047]Acrylic silicon ester monomer 5-30%, ethylenically unsaturated monomer 10-40%, acrylic acid 0.2-2%, rosin 5-20%, initiator 0.1-1%, emulsifier 0.5-3%, bicarbonate...

Embodiment 1

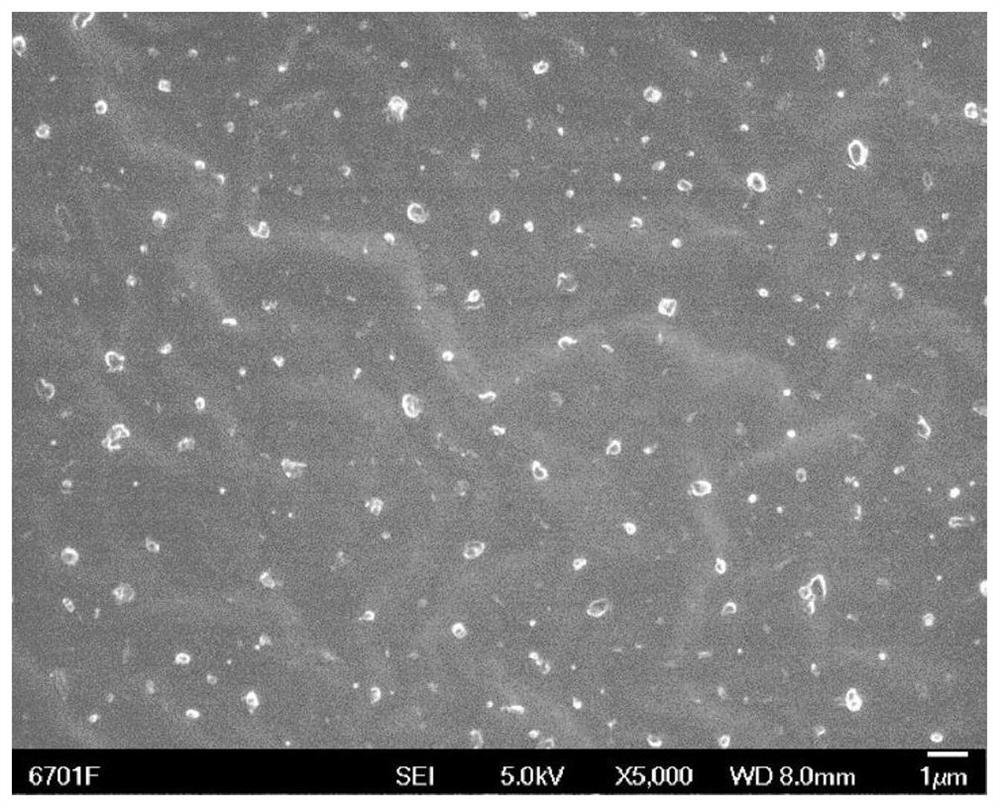

[0097] Preparation of aqueous self-polishing emulsion:

[0098] Weigh 50g of silicon triisopropyl methacrylate, 30g of butyl acrylate, 50g of methyl methacrylate, 16.5g of styrene and 2.4g of acrylic acid, stir and mix evenly, add 50g of rosin and stir to dissolve until the solution is transparent, add 3g of non Ionic emulsifier OP-10, 1.5g of anionic emulsifier sodium dodecylsulfonate and 150g of deionized water were stirred at 30°C and 600r / min for 40min to obtain component A;

[0099] Dissolve 1.4g of initiator ammonium persulfate into 20g of deionized water to obtain component B;

[0100] Add 0.2g of sodium bicarbonate, 30g of deionized water and 100g of component A into a four-necked flask, stir at 30°C and 600r / min for 30min, then add 3.2g of component B, and gradually raise the temperature to 81°C under stirring. After 40 minutes of reaction, the system turned blue, and then continued to stir and react for 40 minutes to obtain a seed emulsion;

[0101] Maintain the he...

Embodiment 2

[0107] Prepare water-based self-polishing emulsion and water-based slurry according to the method of Example 1;

[0108] Mix 35g of water-based self-polishing emulsion, 48g of water-based slurry, 0.6g of ethylene glycol ether and 15.5g of deionized water, fully stir and disperse for 30min under the condition of 300r / min, and then add it to the resulting mixture under the condition of 200r / min Slowly add 0.3 g of water-based leveling agent BYK375 and 0.6 g of water-based defoamer DC65 in sequence, and continue to stir and disperse for 30 minutes after the addition, to obtain a water-based self-polishing antifouling coating with a solid content of 46.2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com