High-strength hot-rolled profile and temperature control and cooling process thereof

A high-strength, profile technology, used in temperature control, metal rolling, etc., can solve the problems of difficulty in meeting strength requirements and high cost, and achieve the effect of increasing ultimate strength, increasing strength yield ratio, and improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

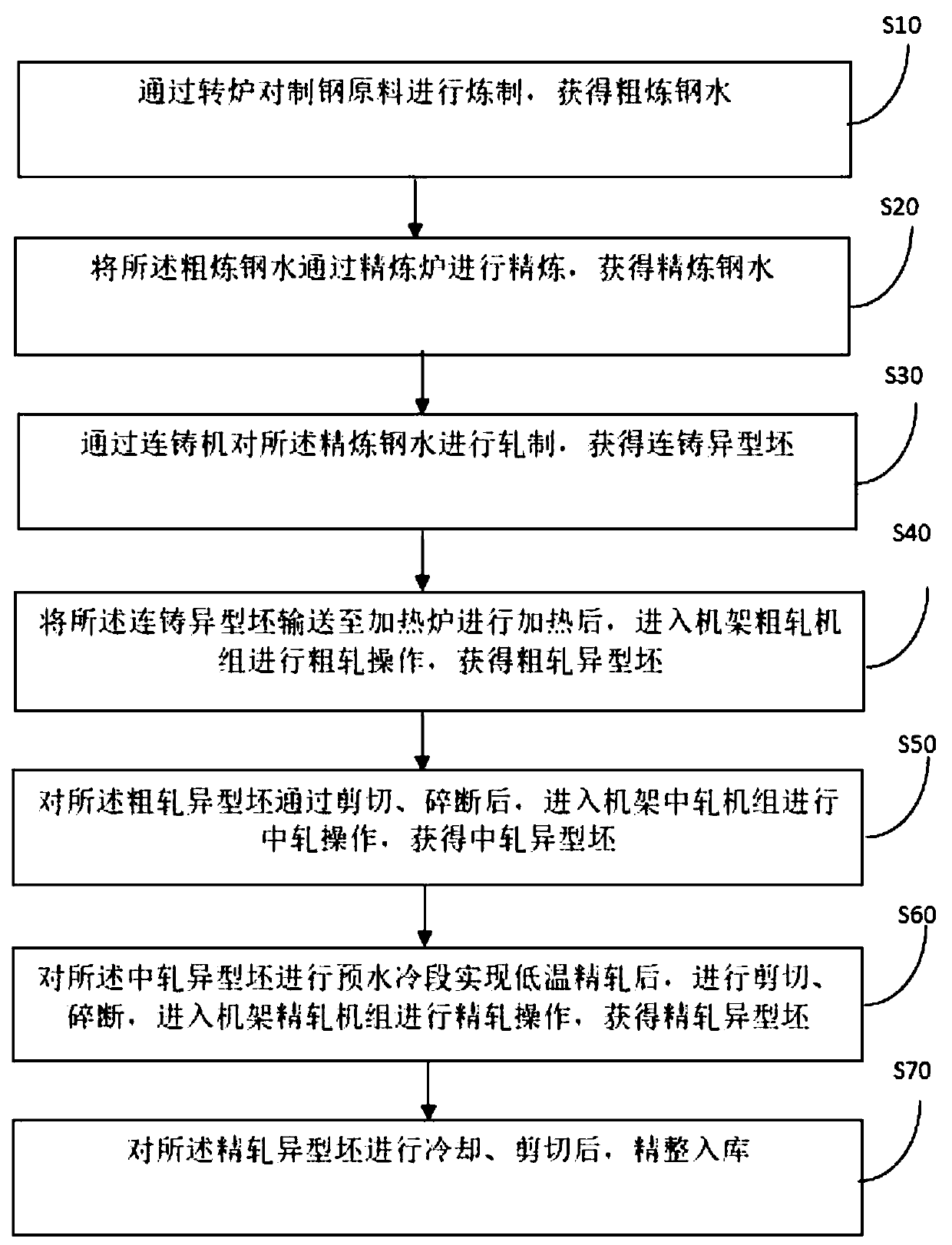

Method used

Image

Examples

Embodiment

[0047] Table 1 is a comparative table of chemical composition between the high-strength hot-rolled profiles of the present invention and existing profiles. Table 2 is a comparison of the mechanical properties of the sample block of the high-strength hot-rolled profile described in the present invention and the existing profile. In Table 2, Rm is the tensile strength, Rel is the lower yield strength, A is the elongation after fracture, and Agt is the elongation.

[0048] Table 1

[0049]

[0050] Table 2

[0051]

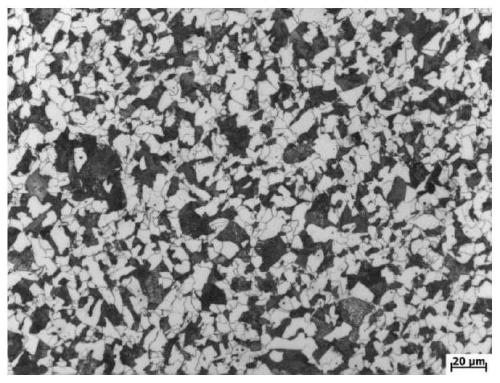

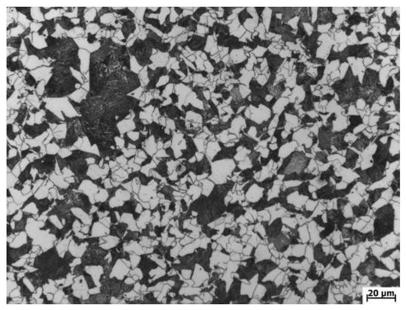

[0052] It can be seen from Table 1 and Table 2 that by controlling V / N at 3.49, 3.56, 3.83, and controlling the niobium content at 0.015% and 0.025%, the smelted billet is rolled to obtain the corresponding mechanical properties. After comparison, V The performance is the most stable when / N is 3.56, and the utilization effect of V and Nb is the best. Compared with existing materials, the yield strength has been significantly improved, and the seismic perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com