A Widened Pulp Tank Structure for Broken Paper Pulper

A pulper and pulper technology, which is used in papermaking, paper recycling, textiles and papermaking, etc., can solve the problems of not making good use of the interaction of pulp flow, low breaking efficiency of broken paper, and long time. Optimized structure, reduced rotor diameter and power consumption, accelerated disintegration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

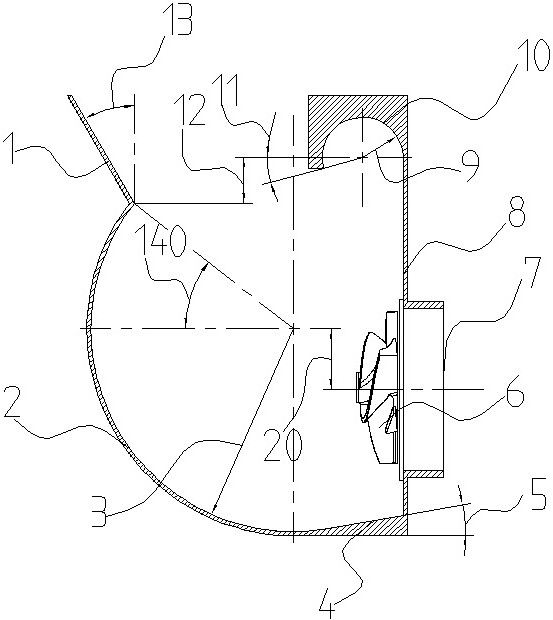

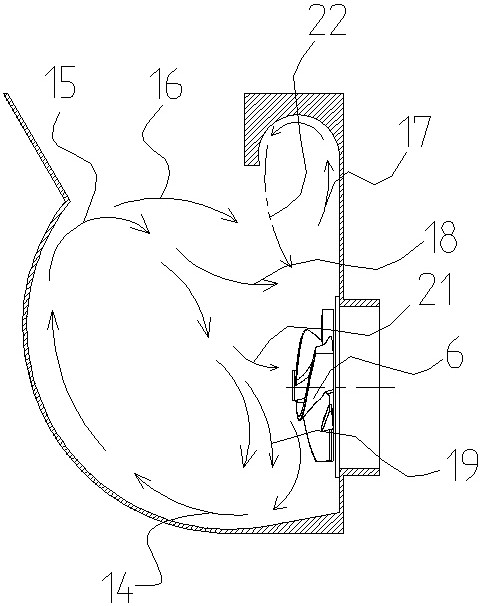

[0028] like Figure 1 to Figure 4 As shown, a widened pulp pool structure for a broke pulper in this embodiment includes a pulp pool, a rotor is arranged in the pulp pool, and the pulp pool consists of a front side wall 2, a rear side wall 8, left and right side walls and The upper open structure enclosed by the pool bottom 4.

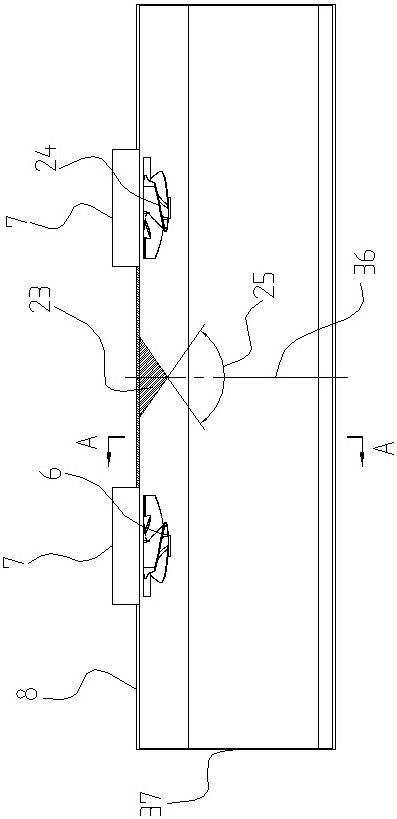

[0029] like figure 1 Shown is a top view of the present invention. At the center of the rear side wall 8 of the slurry tank, there is a guide cone 23 . On its head is a sharp corner 25, the angle of which ranges from 100 degrees to 130 degrees.

[0030] On the left and right sides of the centerline 36 of the pulp pool, two rotors are symmetrically arranged, wherein the rotor 6 turns 26 clockwise (viewed from the direction of the front side wall 2 ), and the rotor 24 turns counterclockwise 27 (from the direction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com