Buffer for subway rail

A buffer and track technology, applied in buffer and subway fields, can solve problems such as unfavorable wheel running, track damage, shaking, etc., and achieve the effect of reducing shock performance, reducing damage and reducing shock effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

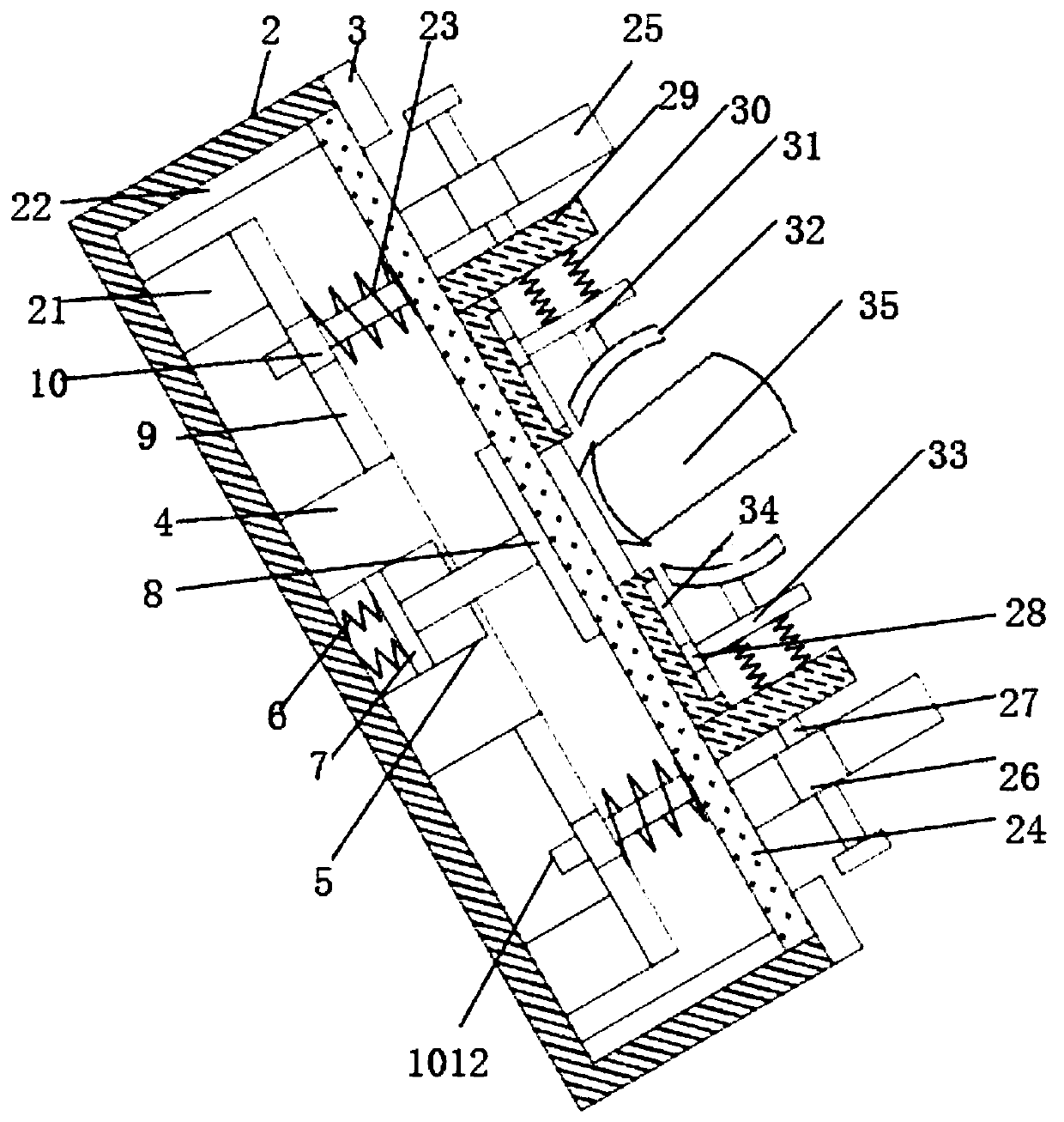

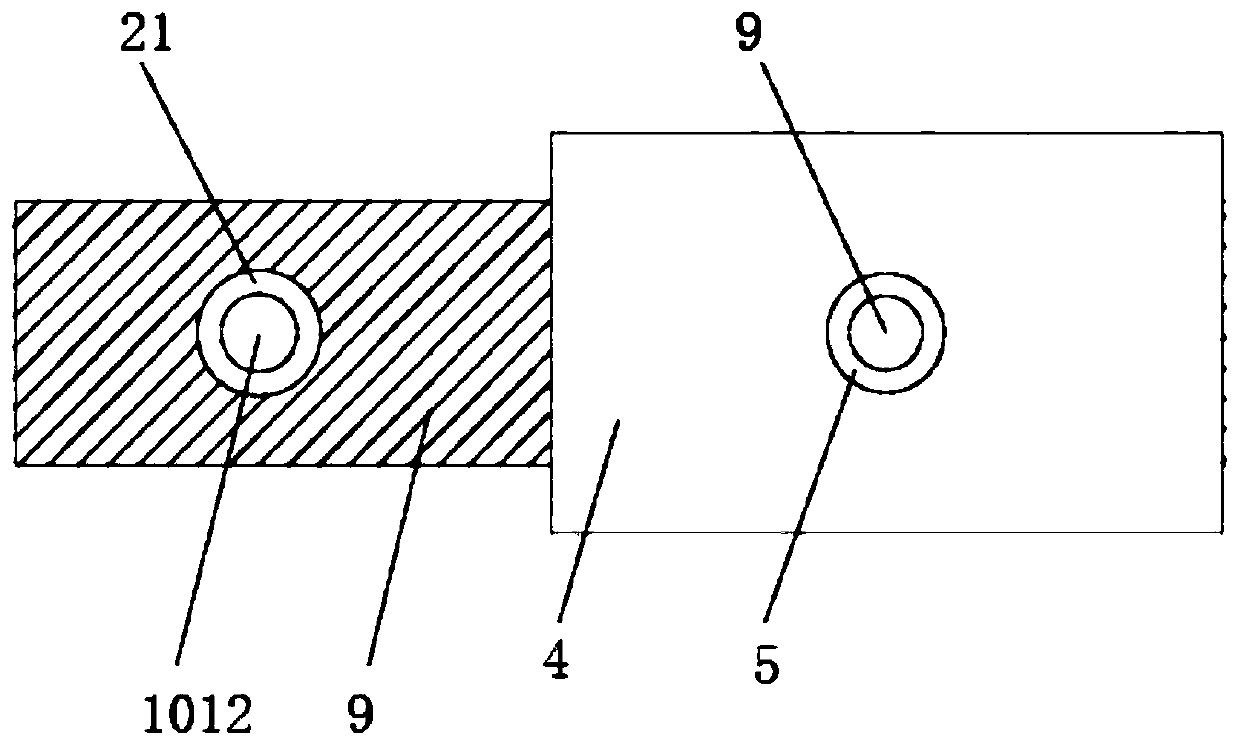

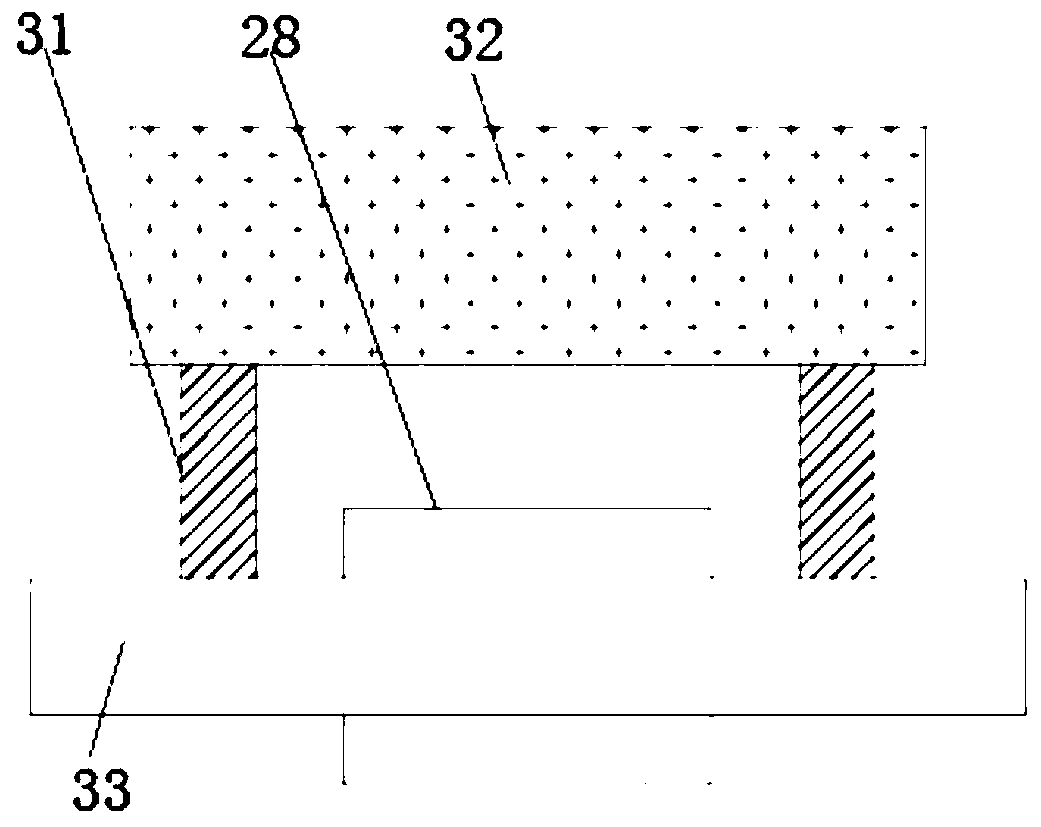

[0022] Such as Figure 1-Figure 3 As shown, the buffer used for the subway track includes a base 2, a shock-reducing device for buffering and a stabilizing device; the device for reducing the shock for buffering includes a positioning plate fixed to the inside of the base 2 4. There is a moving opening 5 in the inside of the positioning plate 4, and the inside of the moving opening 5 can be moved and connected to the fastening block 7. The upper end of the fastening block 7 is fixedly connected to the fastening strip 8, and the fastening The upper end of the bar 8 is fixedly connected to the assembly block 24, and the subway track 35 is given several levels of vertical vibration reduction, which reduces the shock performance better and reduces the shock force of the subway track 35; The positioning block 25 on both sides of the upper end of the block 24, the inside of the positioning block 25 has an adjustment port 26, the inside of the adjustment port 26 is screwed with a scr...

Embodiment 2

[0024] Such as Figure 1-Figure 3As shown, the buffer used for the subway track includes a base 2, a shock-reducing device for buffering and a stabilizing device; the device for reducing the shock for buffering includes a positioning plate fixed to the inside of the base 2 4. There is a moving opening 5 in the inside of the positioning plate 4, and the inside of the moving opening 5 can be moved and connected to the fastening block 7. The upper end of the fastening block 7 is fixedly connected to the fastening strip 8, and the fastening The upper end of the bar 8 is fixedly connected to the assembly block 24, and the subway track 35 is given several levels of vertical vibration reduction, which reduces the shock performance better and reduces the shock force of the subway track 35; The positioning block 25 on both sides of the upper end of the block 24, the inside of the positioning block 25 has an adjustment port 26, the inside of the adjustment port 26 is screwed with a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com