High-rigidity high-speed maglev turnout supporting point arrangement structure and arrangement method

A technology with supporting points and high rigidity, applied in the directions of roads, tracks, buildings, etc., can solve the problems of low rigidity and easy resonance of turnout beams, and achieve the effect of improving comfort and safety, improving resonance problems and strong flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

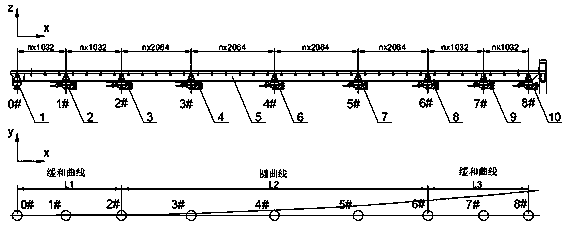

[0023] Embodiment 1: with reference to attached figure 1 and 2 . An arrangement of support points for high-speed maglev turnouts with large stiffness, which consists of straight lines, transitional curves, circular curves, transitional curves and straight lines to form uninterrupted high-speed maglev turnouts, and the connection points between the straight lines, transitional curves, circular curves, transitional curves and straight lines are Linear conversion point, the linear conversion point is the supporting point of the driving trolley.

[0024] The uninterrupted connection point between the transitional curve and the circular curve is the 2# driving trolley, the uninterrupted connection point between the circular curve and the transitional curve is the 6# driving trolley, and the uninterrupted connection point between the transitional curve and the straight line is the 8# driving trolley .

[0025] Arrange one or more supporting trolleys between 2#, 6#, and 8# adjacen...

Embodiment 2

[0030]Embodiment 2: On the basis of Embodiment 1, a method for arranging support points of large-rigidity high-speed maglev turnouts, the key trolley arrangement position: according to the line shape requirements of straight line-transition curve-circle curve-transition curve straight line switch, it is divided into 5 points The plane combination composed of segment functions is used to fit the bending curve of the turnout steel girder. The turnout girder must reach the deformation curve composed of the transitional curve-circular curve-transitional curve under the drive of concentrated load; set up four trolley support points, Among them, 0#, 2#, 6#, and 8# trolleys are placed on the linear conversion points to ensure that the linearity of the turnout beam meets the curve requirements after the four support points are in place; the layout of the supporting trolleys: the layout position of the supporting trolleys needs to be considered The position of the stator and functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com