Trash holding net cleaning system

A technology of cleaning system and trash net, which is applied in the field of trash net cleaning system, can solve problems such as difficult cleaning, poor cleaning effect, and inability to maintain stability, and achieve the effect of strong cleaning ability and guaranteed work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

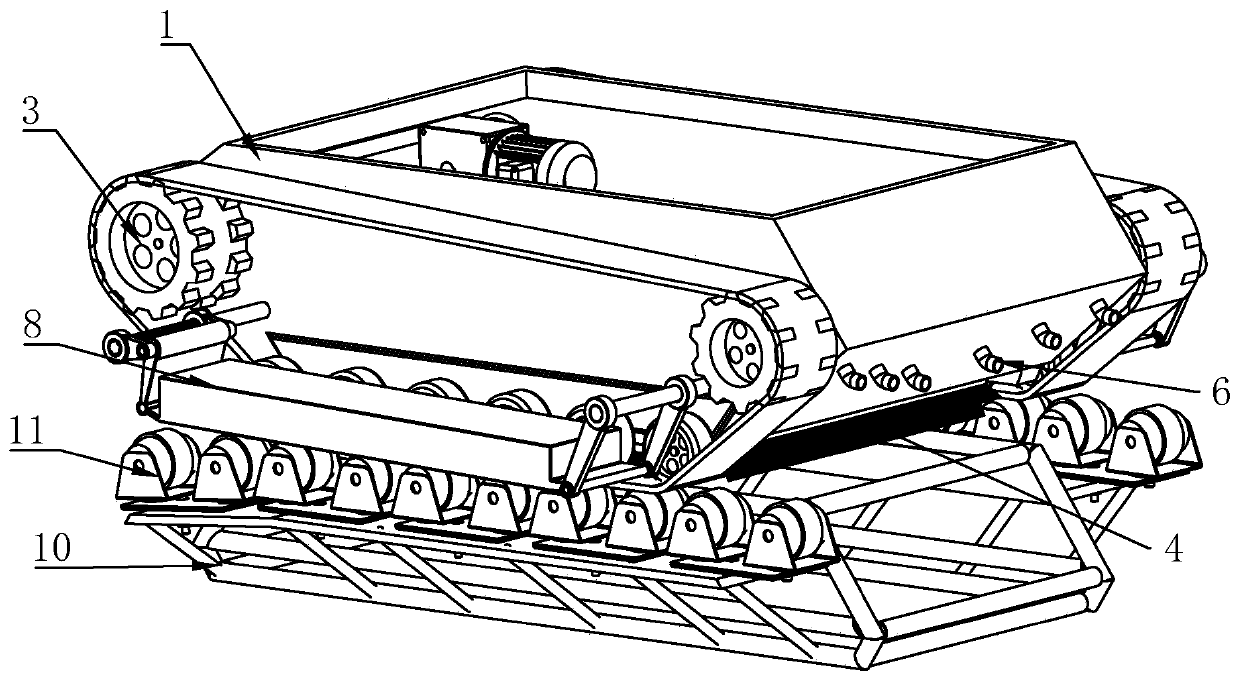

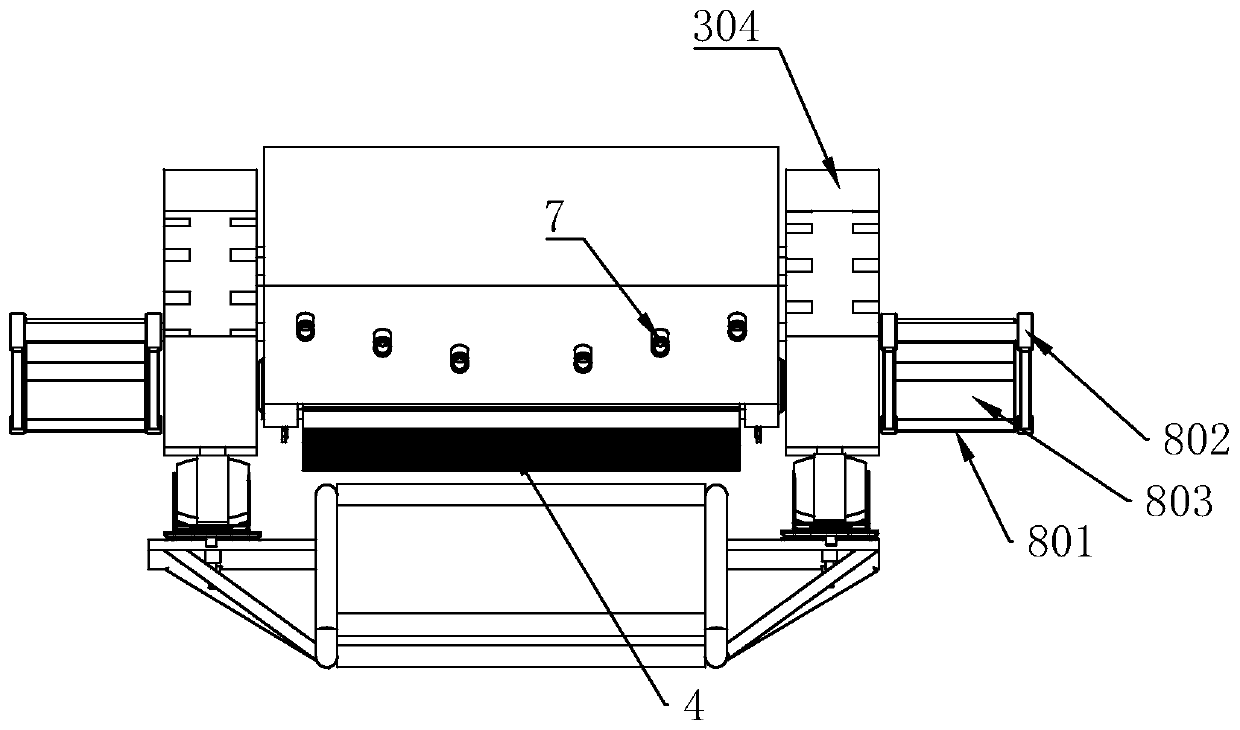

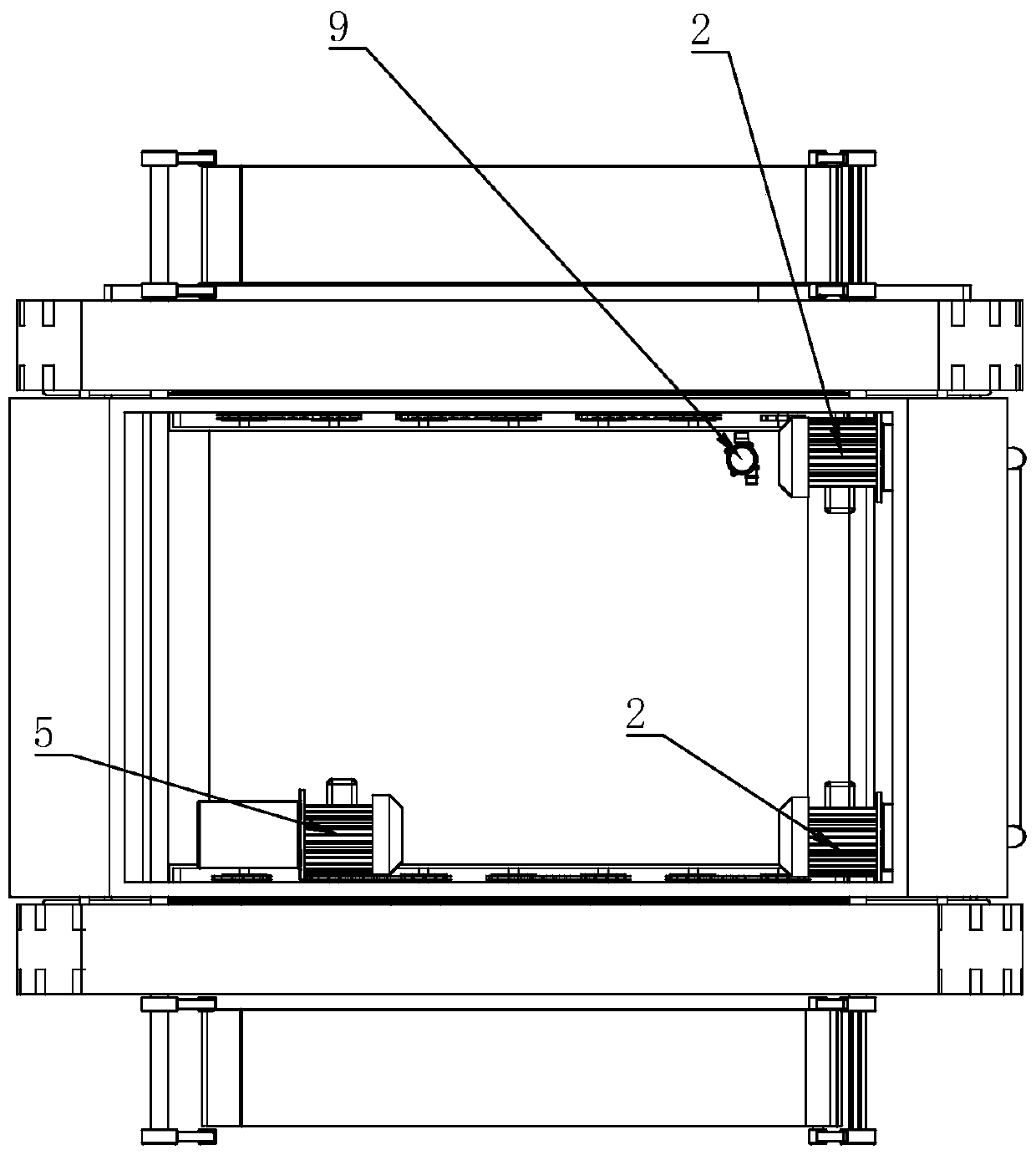

[0026] Such as Figure 1-Figure 4 As shown, the present invention provides a cleaning system for the trash screen, which includes a cleaning mother part and a cleaning sub-part which are used in cooperation with each other and arranged on both sides of the trash screen, so as to clean the trash screen. A magnetic flip device 8 is provided on the cleaning master part, and a magnetic part is provided on the cleaning sub-part. By adjusting the distance between the magnetic flip device 8 and the magnetic part and the magnetized area, the magnetic flip device 8 and the magnetic part can be adjusted. The magnitude of the magnetic attraction between the cleaning master and the cleaning sub-parts is realized according to the corresponding buoyancy in water to adjust the required magnetic attraction to ensure the working stability of the cleaning master and the cleaning sub-parts in water.

[0027] Further, the cleaning mother part includes a cabin body 1, a crawler belt transmission d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com