Hinge for glass doors

A technology of hinges and hinges, which is applied to hinges with pins, applications, household appliances, etc., to achieve the effects of simple connection, simplified assembly and adjustment, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

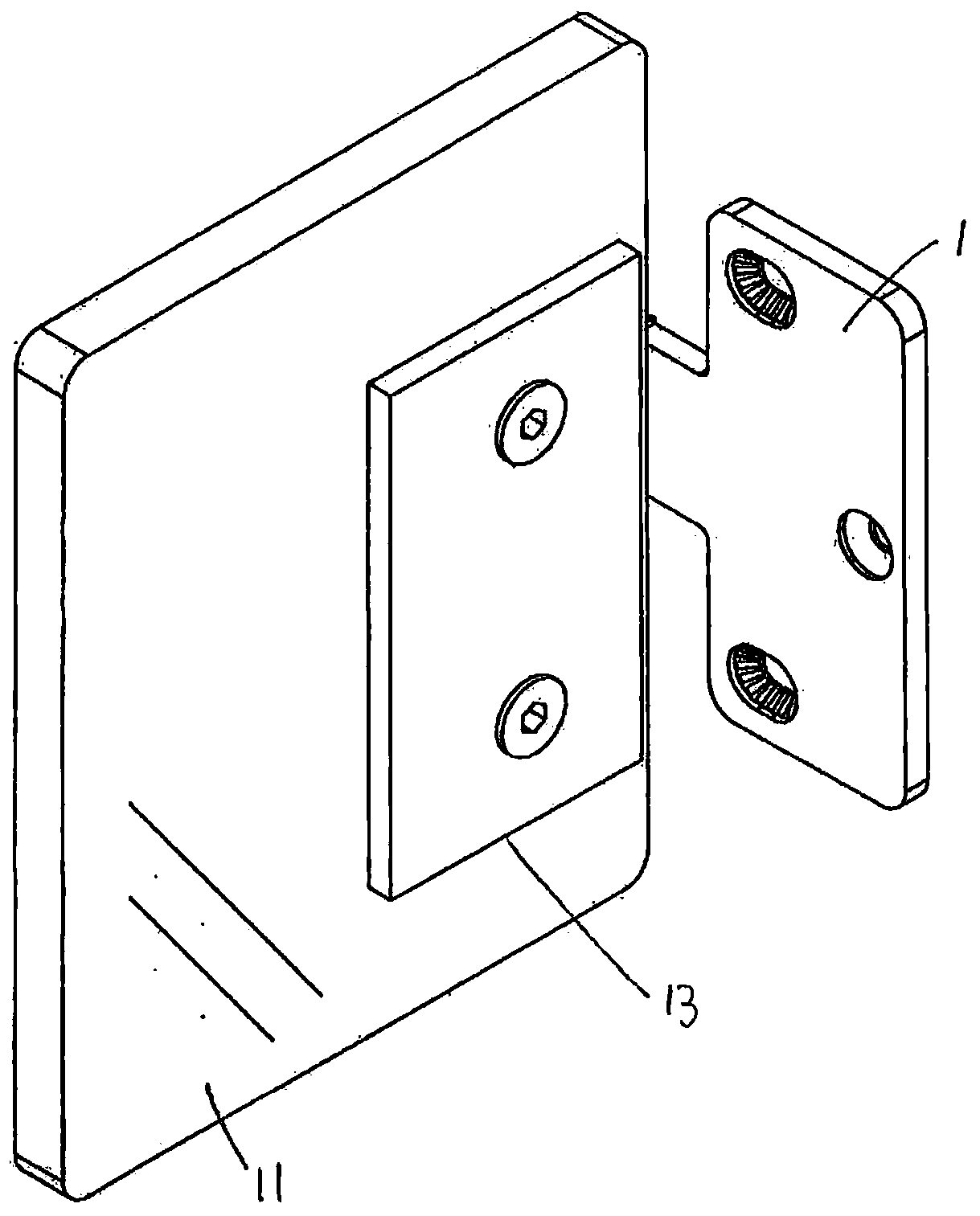

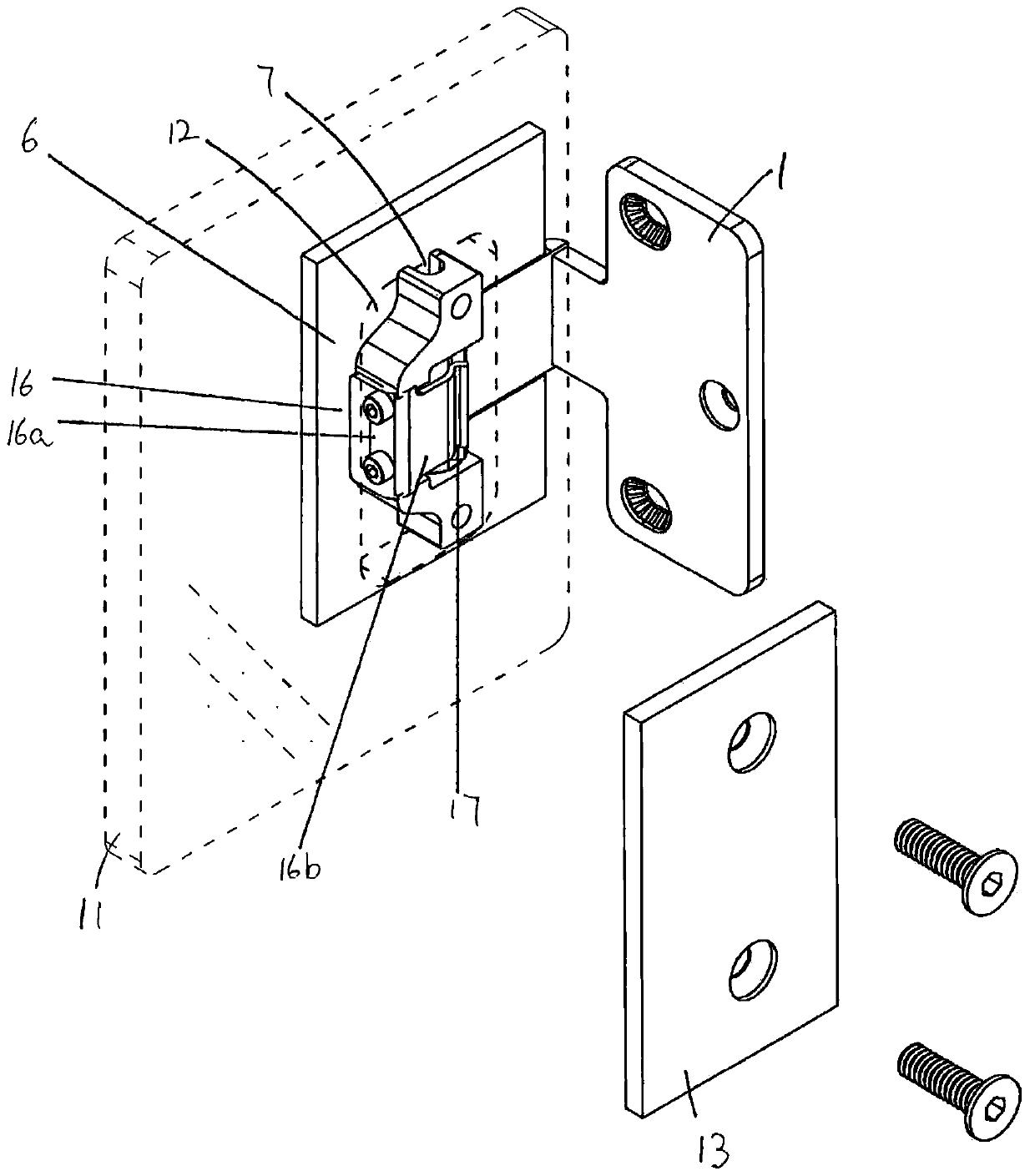

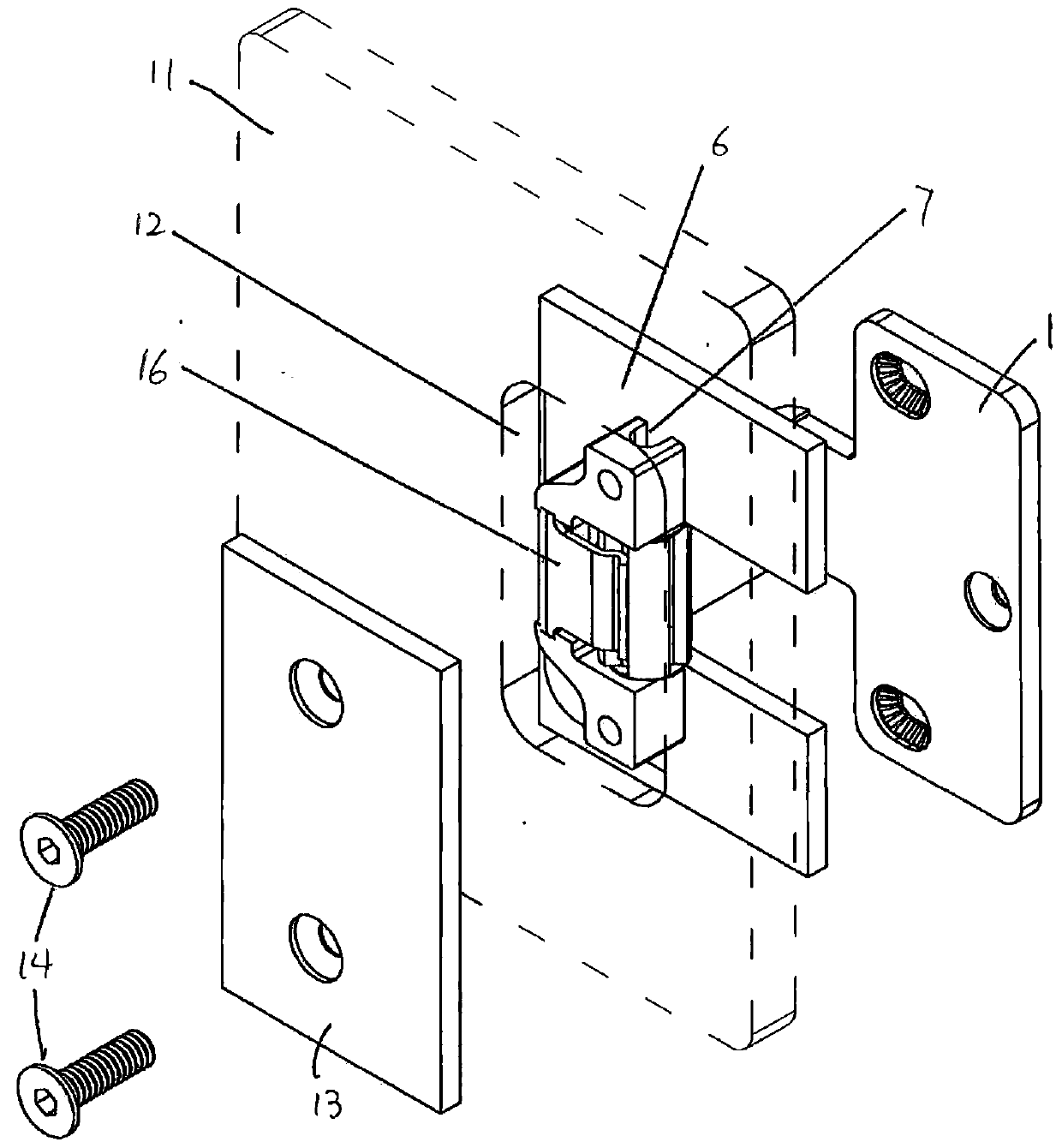

[0085] Figures 1 to 6 The hinge shown includes a mounting which may be a mounting plate 1 and which may be provided with fixings such as holes into which bolts or screws may be inserted to secure the mounting plate to a door frame, wall or other structure. In alternative embodiments, the mount may include clamping means for adjacent door panels. Arm 2 extends perpendicularly from mounting plate 1 . The first end of the arm 2 is fixed on the mounting plate. The second end of the arm 2 is integral with a collar 3 having an axial hole 4 in which a hinge shaft or pin 5 is rotatably received such that the shaft or pin 5 lies on the hinge axis 5a.

[0086] The hinge body 6 has upper and lower housings with an eye 7 arranged to receive a pin or the end of the shaft 5 so that the hinge body 6 can pivot relative to the mounting plate 1 .

[0087] The collar 3 is part-cylindrical with axial bores 4 arranged along the collar axis. The collar 3 comprises a pair of engaging formations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com