Drilling device and drilling method for downhole pneumatic rock crushing foam slag discharge

A technology of drilling device and pneumatic impactor, which is applied to the driving device for drilling in the wellbore, earthwork drilling, flushing the wellbore, etc., which can solve the problems of large dust pollution, low product price and high performance requirements, and achieve improvement The construction environment, the reduction of dust hazards, and the effect of ensuring drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

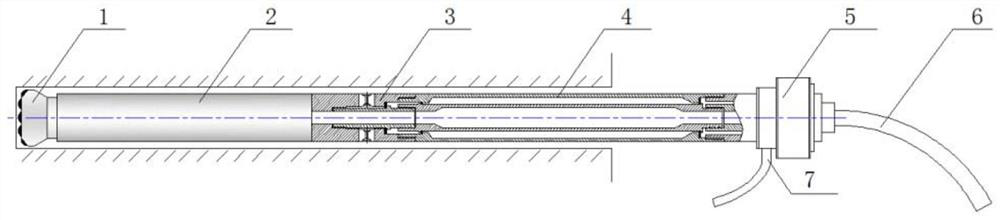

[0045] Such as Figure 1 to Figure 4 As shown, this embodiment provides a drilling device for downhole pneumatic rock crushing and foam slag discharge, which includes a hammerhead 1, a pneumatic impactor 2, a double-wall jet joint 3, a double-wall drill pipe 4 and a double-wall drill pipe connected in sequence. Air blower 5, and the air duct 6 that is located at the rear end of double-wall air blower 5 and the water pipe 7 that is located at double-wall air blower 5 sides.

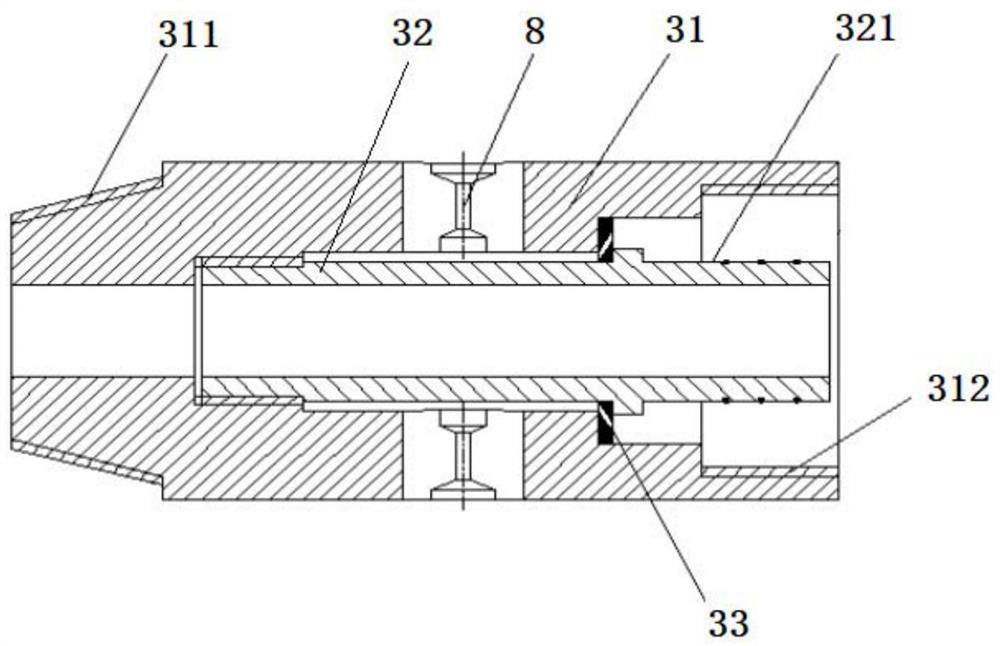

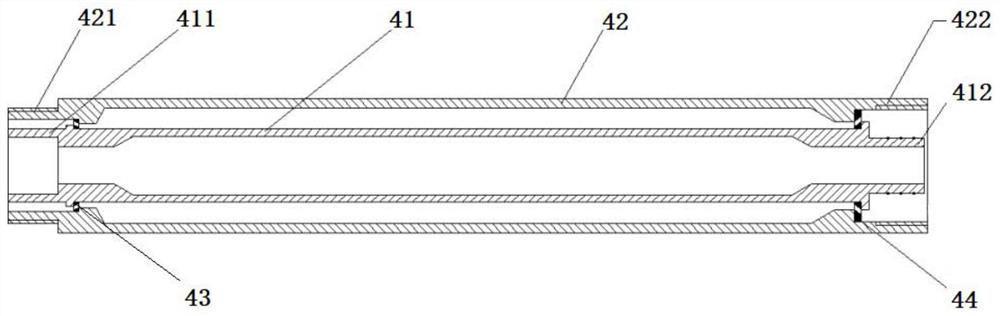

[0046]The double-wall injection joint 3, the double-wall drill pipe 4 and the double-wall air blower 5 are all double-layer structures. The structures are mutually sealed and communicated annular passages, and one end of the annular passage is sealed and communicated with the water pipe 7, and the other end of the annular passage passes through a plurality of nozzles 8 arranged on the outer tube body 31 of the double-wall spray joint 3 It communicates with the outside to spray the liquid delivered to the ...

Embodiment 2

[0061] This embodiment provides a drilling method using the downhole pneumatic rock crushing foam slag discharge drilling device of embodiment 1, including the following steps:

[0062] Step 1, Rotary drilling and opening: According to the design requirements, adjust the inclination and azimuth angle, stabilize the drilling equipment, connect the composite drill bit, ordinary outer flat drill pipe and water feeder, and then drill 3-5m or until Hard rock formation section, and then lift drill;

[0063] Step 2, connect and lower the impact drilling tool into the hole: connect the hammer head, pneumatic impactor, double-wall jet joint, double-wall drill pipe and double-wall air blower in sequence, open the air supply pipeline to connect the air pipe and the water pump to connect the water pipe , carry out debugging, confirm that the impactor can work normally, and the liquid at the nozzle can be ejected normally, and then start drilling until the hammer head is close to the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com