A safety assurance method for controlled fracturing in underground coal mines

A technology for safety assurance and coal mines, applied in earthwork drilling, boreholes/well components, instruments, etc., can solve problems such as gas overrun accidents, hydraulic fracturing technology not intrinsically safe, etc., and achieve the effect of ensuring safe implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

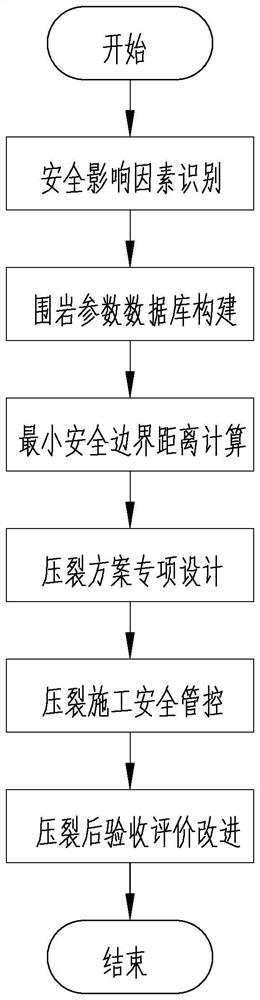

[0092] A safety guarantee method for controlled fracturing in a coal mine, comprising the following steps:

[0093]The first step is the identification of safety-influencing factors: including the determination of weak points in the fracturing area, the type, location, scale, and distance of the free surface;

[0094] The second step is to build the surrounding rock parameter database: including collecting coal seam, roof and floor samples in the fracturing area, laboratory tests and on-site measurements to obtain the in-situ stress, pressure coefficient, uniaxial compressive strength, and Poisson's ratio in the fracturing area and other surrounding rock foundation parameters;

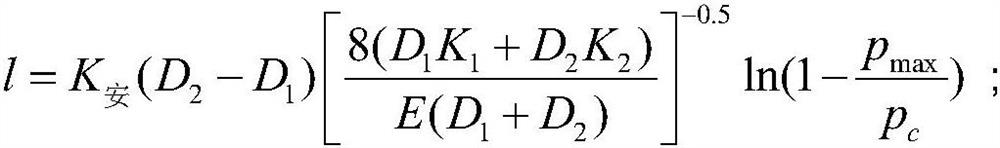

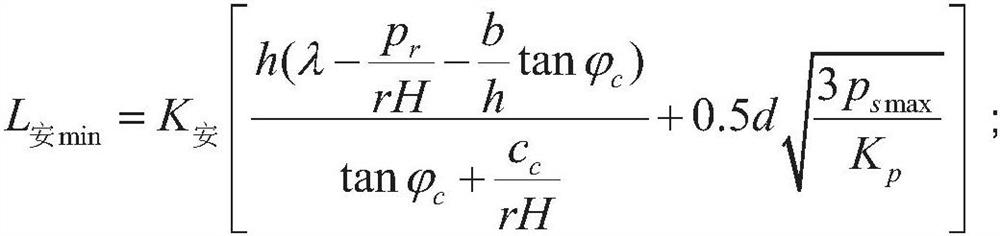

[0095] The third step is the calculation of the minimum safe boundary distance: including calculating the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com