Method and device for measuring gas production rate of natural gas hydrate exploitation

A measuring device and technology for hydrate, applied in the directions of measuring device, volume measuring instrument/method, measuring capacity, etc., can solve the problems of accurate and safe measurement of natural gas hydrate, large gas flow error, influence of experimental results, etc. Easy to set up, prevent dangerous drainage, measure the effect of simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

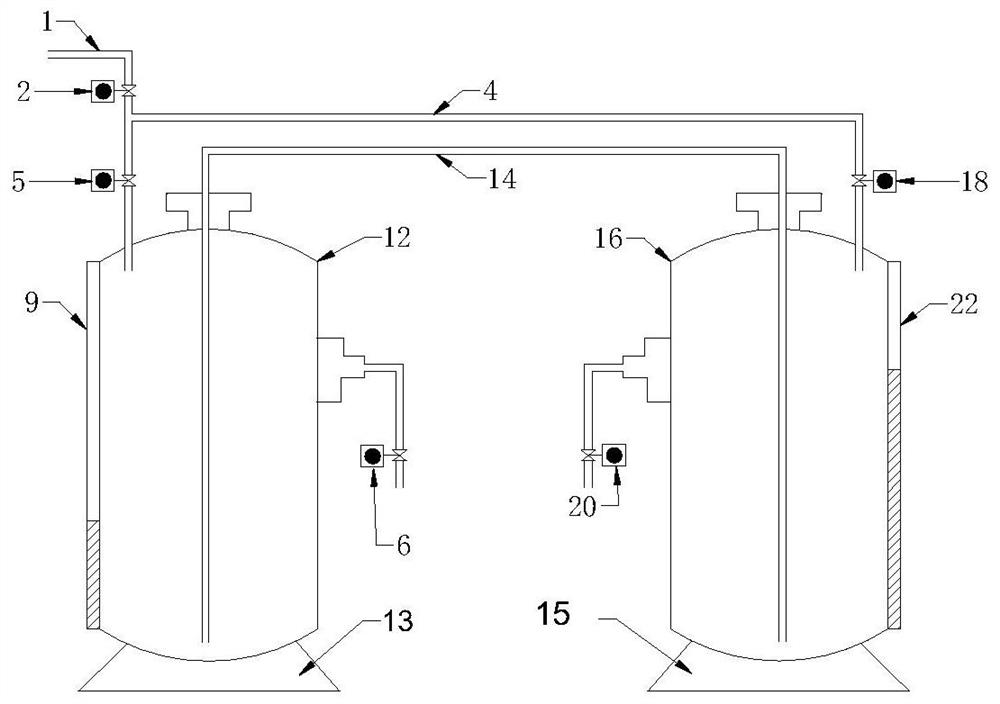

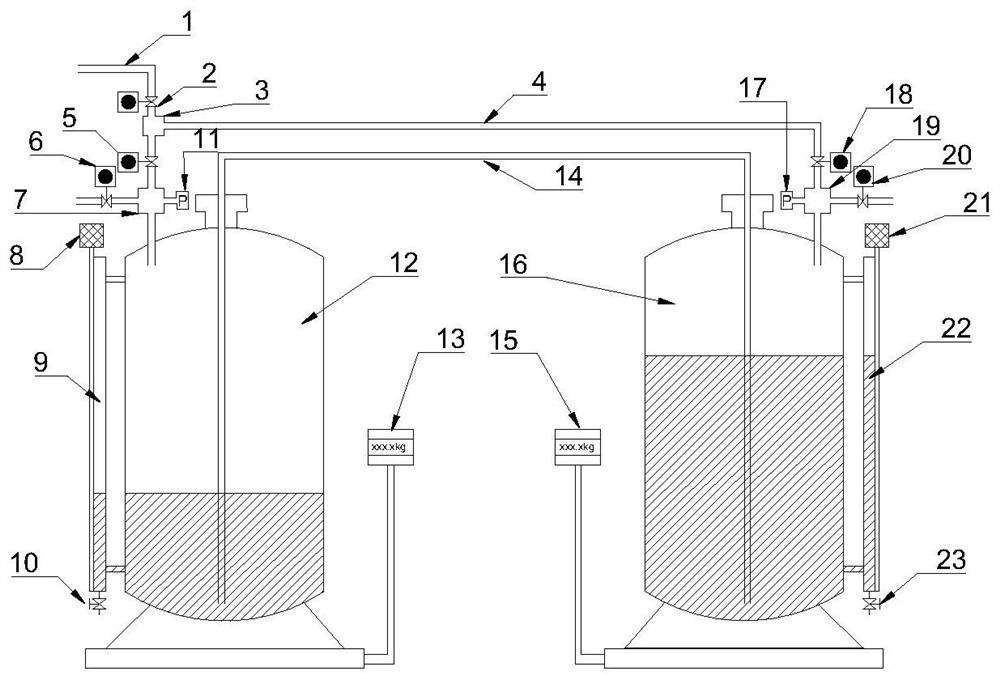

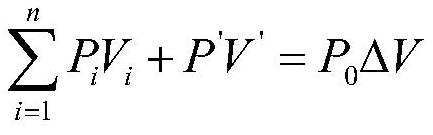

[0034] as attached figure 1 As shown, a method for measuring the gas production of natural gas hydrate production, the method is used in a measuring device, the measuring device includes two tanks, the two tanks are respectively connected through an exhaust pipeline and a drainage pipeline, and the two described There are different volumes of water in the tank, and the method includes the following steps: connecting the methane gas produced by natural gas hydrate exploitation into the tank with relatively high liquid level; draining the water replaced by the methane gas through the drainage pipeline into the tank with a relatively low liquid level, and at the same time the tank with a relatively low liquid level is exhausted and decompressed; when the pressure of the measuring device reaches the set pressure safety upper limit or the liquid level falls to the set liquid level safety lower limit, Trigger the tank inversion mechanism. At this time, because the liquid levels of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com