Graphene heating plate

A graphene and heating plate technology, used in electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of leaking floors, large power consumption of air conditioning auxiliary heating, and large damage, and achieve the effect of convenient replacement and safe power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

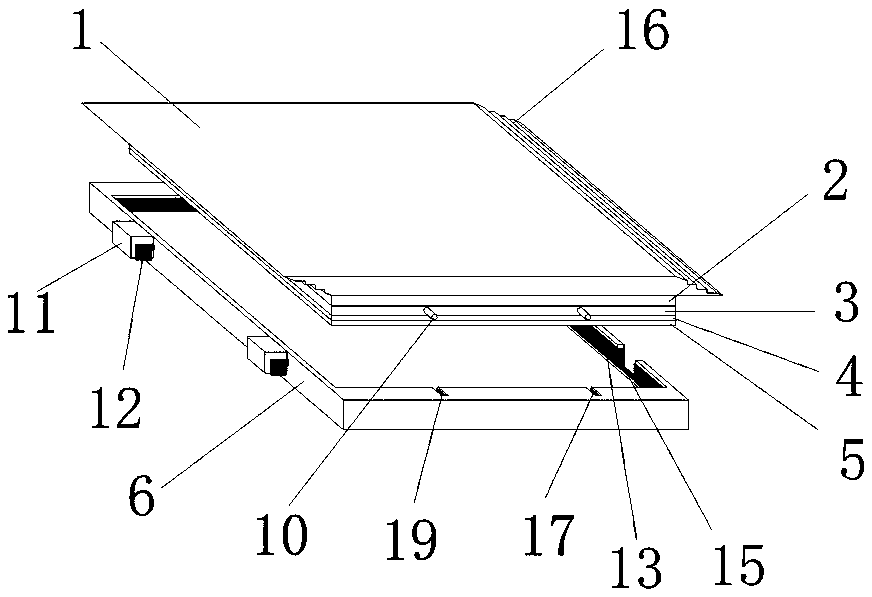

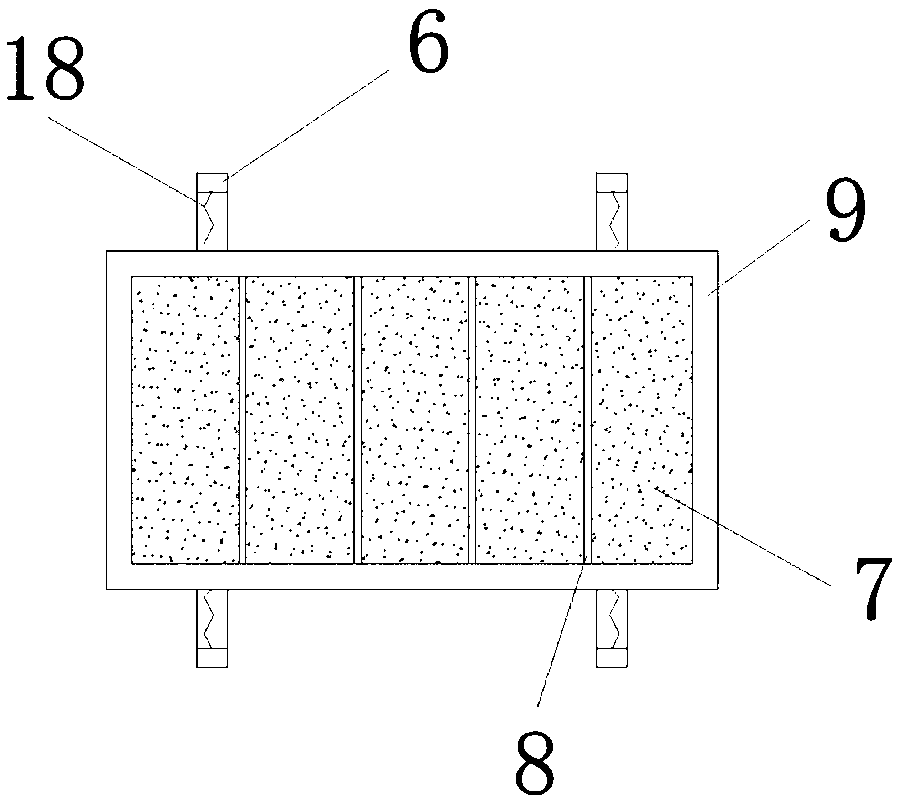

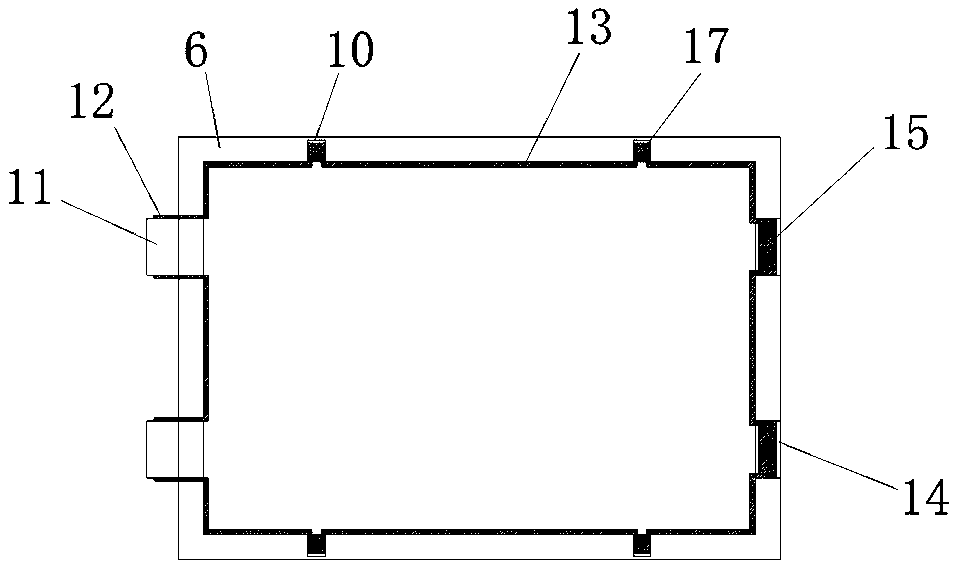

[0019] Such as Figure 1-4 As shown, the graphene heating plate includes an outer plate layer 1, a thermally conductive connection layer 2, a graphene heating layer 3, a heat insulating layer 4, a waterproof layer 5, and a conductive frame 6, and is characterized in that the graphene heating layer 3 and the outer plate layer 1. The lower end of the graphene heating layer 3 is fixedly connected to the heat-conducting connection layer 2. The lower end of the heat-insulating layer 4 is laid with a waterproof layer 5. The outer plate layer 1, the heat-conducting connection layer 2, the graphene heating layer 3, and the heat-insulating layer 4. The board formed by the waterproof layer 5 is placed in the conductive frame 6. The middle part of the graphene heating layer 3 is a rock wool layer 7, and graphene filaments 8 are arranged on the rock wool layer 7, and the two ends of the graphene filaments 8 Connect with the edge of the graphene heating layer 3, the edge of the graphene he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com