A solar greenhouse metal film heat collection and release device

A technology of solar greenhouse and metal film, applied in the field of solar greenhouse, can solve the problems of waste of heat energy during the day, low temperature of greenhouse, slow heat conduction speed of pebble layer, etc., so as to reduce the use area, increase the heat absorption efficiency, and be conducive to the preservation of heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

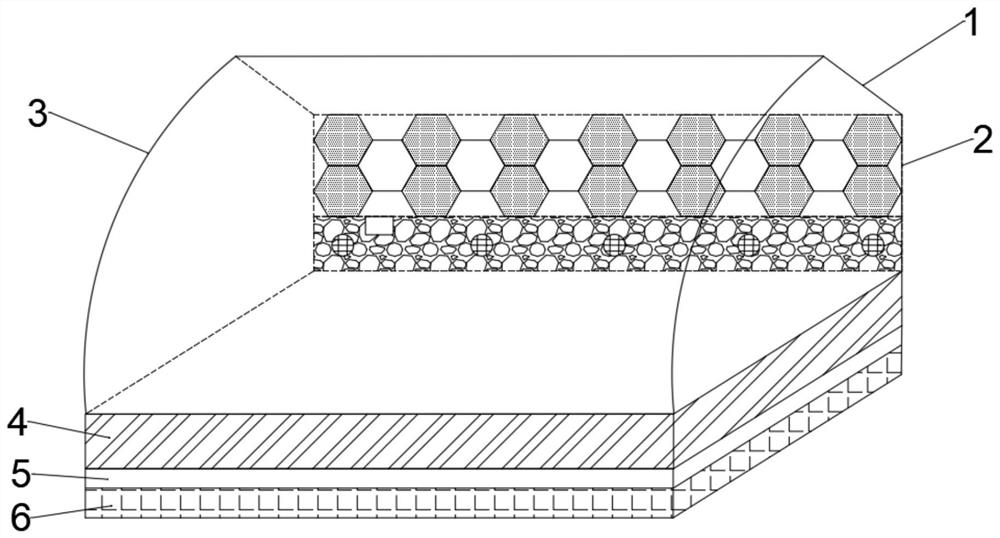

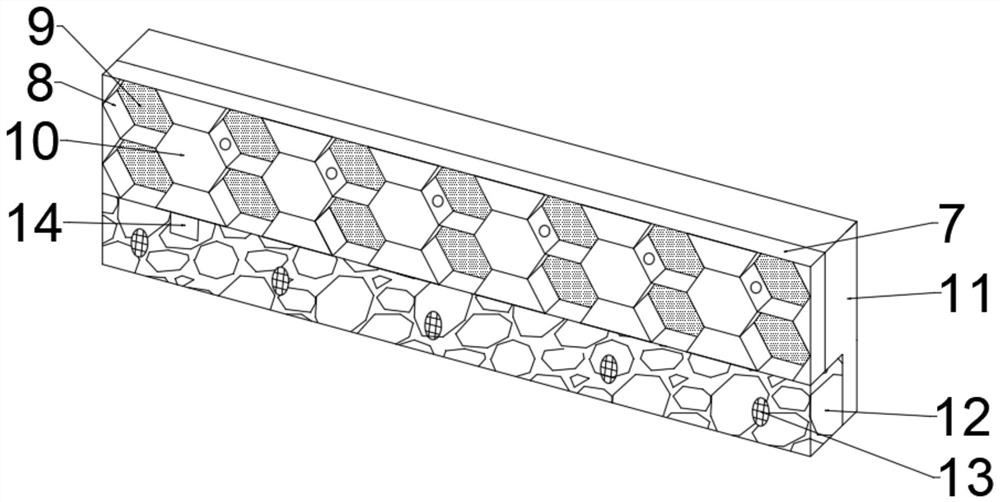

[0033] Embodiment one: if Figure 1-7 As shown, a solar greenhouse metal film heat collection and release device is characterized in that: it includes a back slope 1, a wall 2 and a shed surface 3; a wall 2 is connected to the bottom of the back slope 1, and the wall 2 is used to absorb heat energy during the day; There is a shed surface 3 connected to the front of the back slope 1, and the shed surface 3 is transparent, which can accommodate sunlight to shine on the planted crops; a soil layer 4 is provided under the shed surface 3 for planting crops; The heat insulation layer 5 is used for better heat storage of the circulating water layer 6, preventing part of heat energy from radiating from the circulating water layer 6, and at the same time blocking heat energy to prevent the temperature under the soil layer 4 from being too high and thus affecting the growth of crops. A circulating water layer 6 is arranged below the heat insulation layer 5 .

[0034] Body of wall 2 com...

Embodiment 2

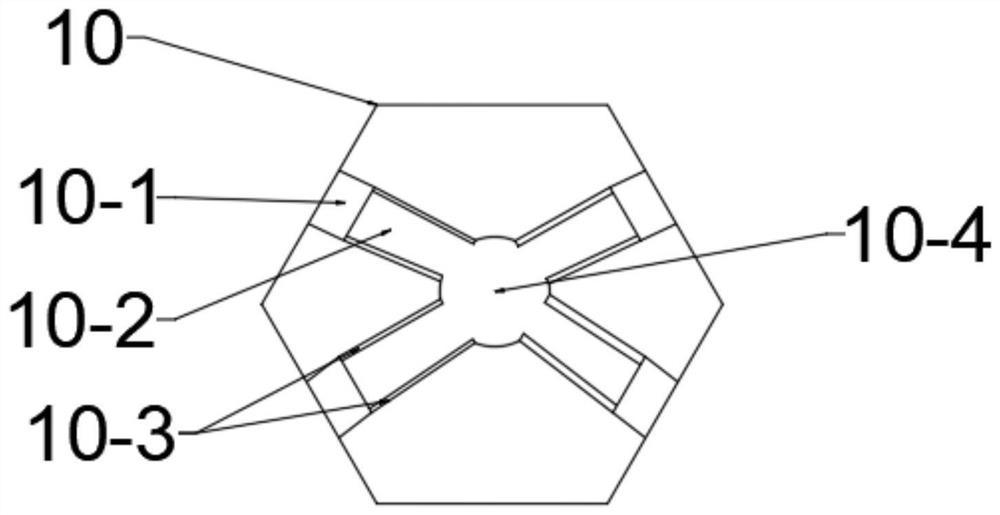

[0041] Embodiment two: if Figure 8 As shown, the main difference from the first technical solution is that the gap adjustment device in the pebble layer 12 is realized in a different way, including a hydraulic push rod 22, a second transmission rod 23 and a branch 24; the hydraulic push rod 22 is electrically connected to the power supply 21 Connected, the power supply 21 is used to provide the electric energy of the hydraulic push rod 22; The second transmission rod 23 is provided with a number of branches 24, and when the second transmission rod 23 moves back and forth, the branches drive the pebbles to move.

[0042] The angle formed by the extension direction of the second transmission rod 23 and the branch 24 is an acute angle. . When the second transmission rod 23 moves toward each other, the acute angle is conducive to gathering the pebbles to reduce the gap between the pebbles, and finally reduces the heat conduction efficiency of the pebbles; when the second transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com