Workbench for hinge machining

A workbench and hinge technology, which is applied to metal processing equipment, folding plates, perforating tools, etc., can solve the problems of inconvenient adjustment of the punching distance, and achieve fast clamping speed, convenient stamping processing, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

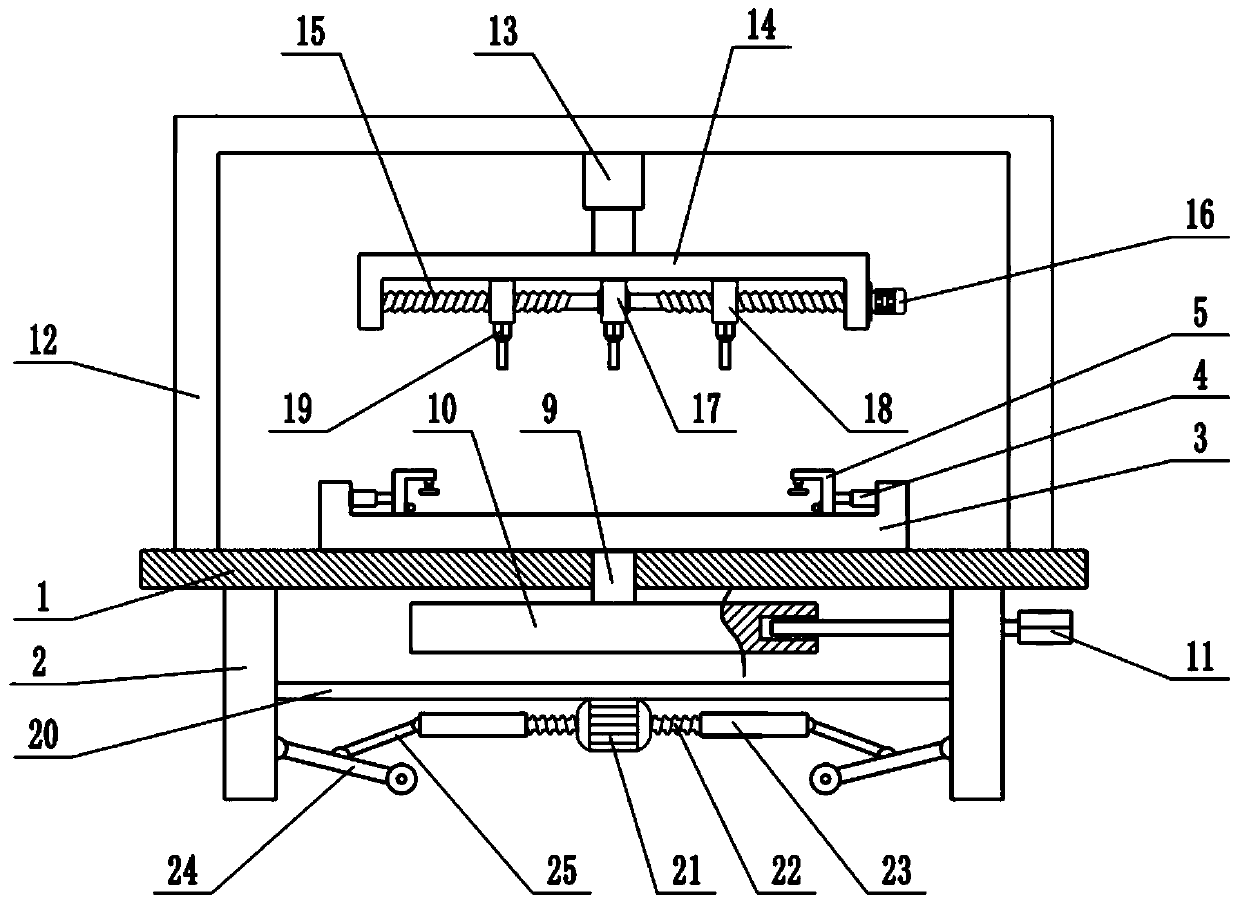

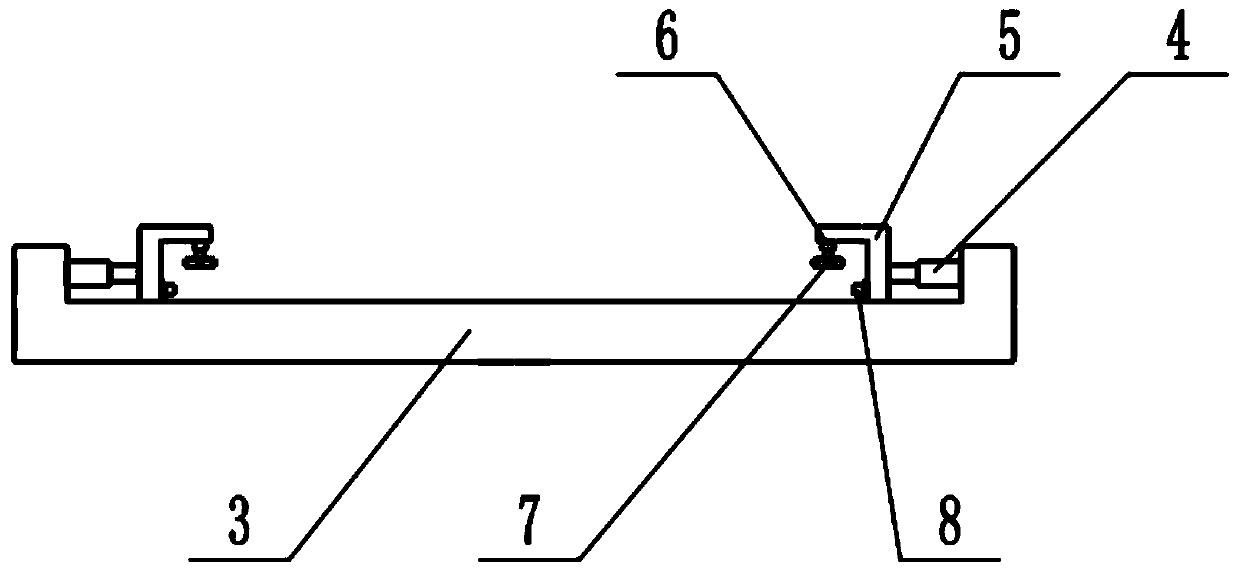

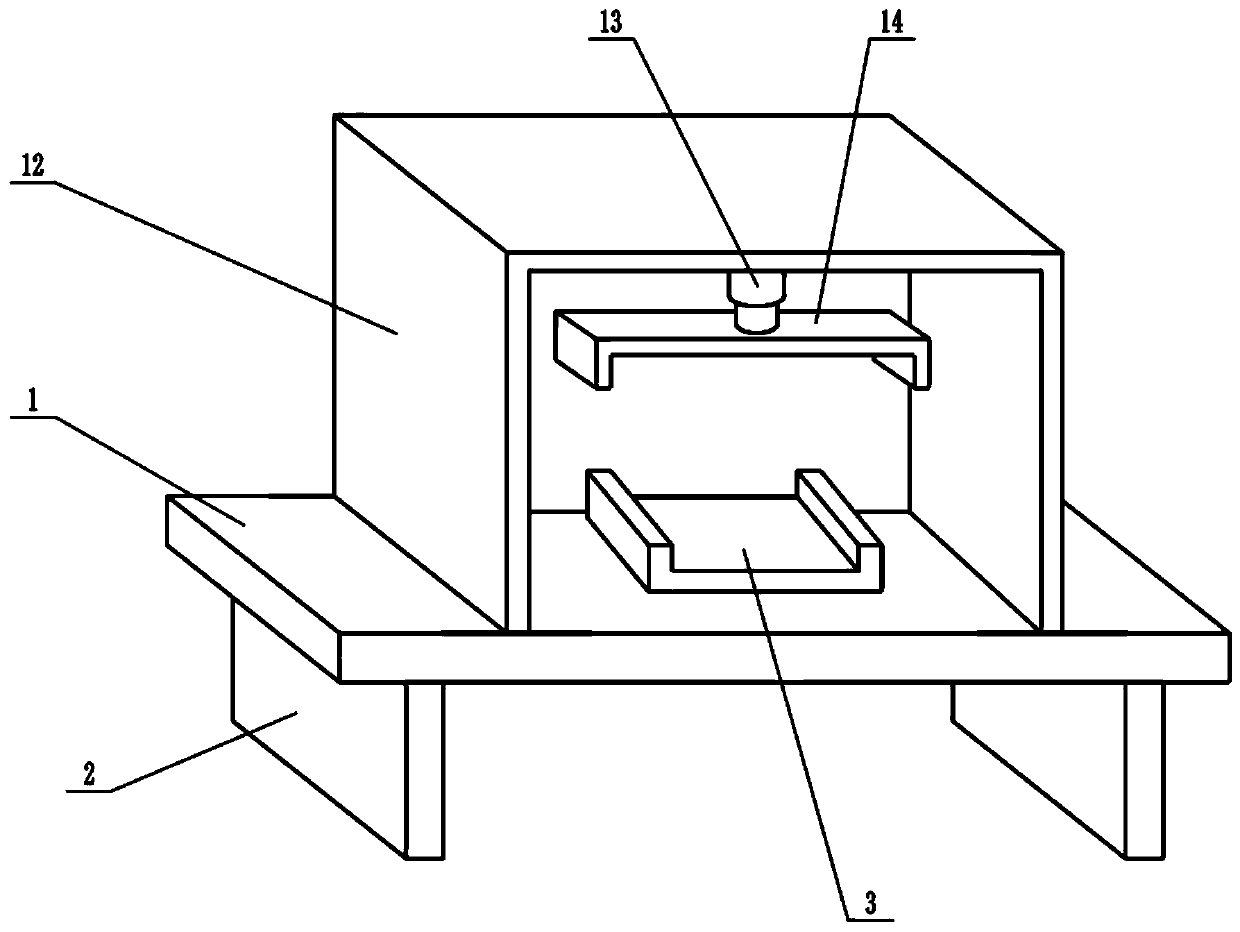

[0022] see Figure 1-3 , In the embodiment of the present invention, a workbench for hinge processing includes a workbench 1, a support plate 2, a rotary table 3, a third telescopic mechanism 13 and a stamping die 19. The bottom of the workbench 1 is fixedly connected with a support Plate 2, a fixing frame 12 is fixedly connected to the upper surface of the worktable 1, a third telescopic mechanism 13 is fixedly connected to the top of the fixing frame 12, the third telescopic mechanism 13 is an electric hydraulic telescopic cylinder, and the lower end of the third telescopic mechanism 13 is fixedly connected There is a lifting frame 14, a bidirectional screw rod 15 is installed inside the lifting frame 14, the left and right ends of the bidirectional screw rod 15 are respectively connected to the side wall of the lifting frame 14 in rotation, and a fixing block 17 is installed inside the lifting frame 14, and the fixing block 17 Located in the middle of the lifting frame 14, ...

Embodiment 2

[0024] On the basis of Embodiment 1, a moving mechanism is installed below the worktable 1, and the moving mechanism includes a mounting plate 20, a biaxial motor 21, a driving screw 22, a sleeve 23, a connecting rod 24 and a movable rod 25. The worktable 1 There is a mounting plate 20 below the mounting plate 20, the end of the mounting plate 20 is fixedly connected with the support plate 2, and the lower surface of the mounting plate 20 is fixedly connected with a biaxial motor 21. The biaxial motor 21 is a forward and reverse rotation motor. The two shaft extension ends are respectively installed with a driving screw 22, the end of the driving screw 22 is sleeved with a sleeve 23, the driving screw 22 is threadedly connected with the sleeve 23, and the end of the sleeve 23 is hinged with a movable rod 25, A connecting rod 24 is hinged on the side wall of the support plate 2, the lower end of the movable rod 25 is hinged with the middle of the connecting rod 24, and a roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com