Electric clipper with refrigeration structure

A technology of electric clippers and refrigerators, applied in metal processing, etc., can solve problems such as low efficiency and unsatisfactory heat dissipation, and achieve the effects of avoiding voltage requirements, improving battery life, and reducing blade wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

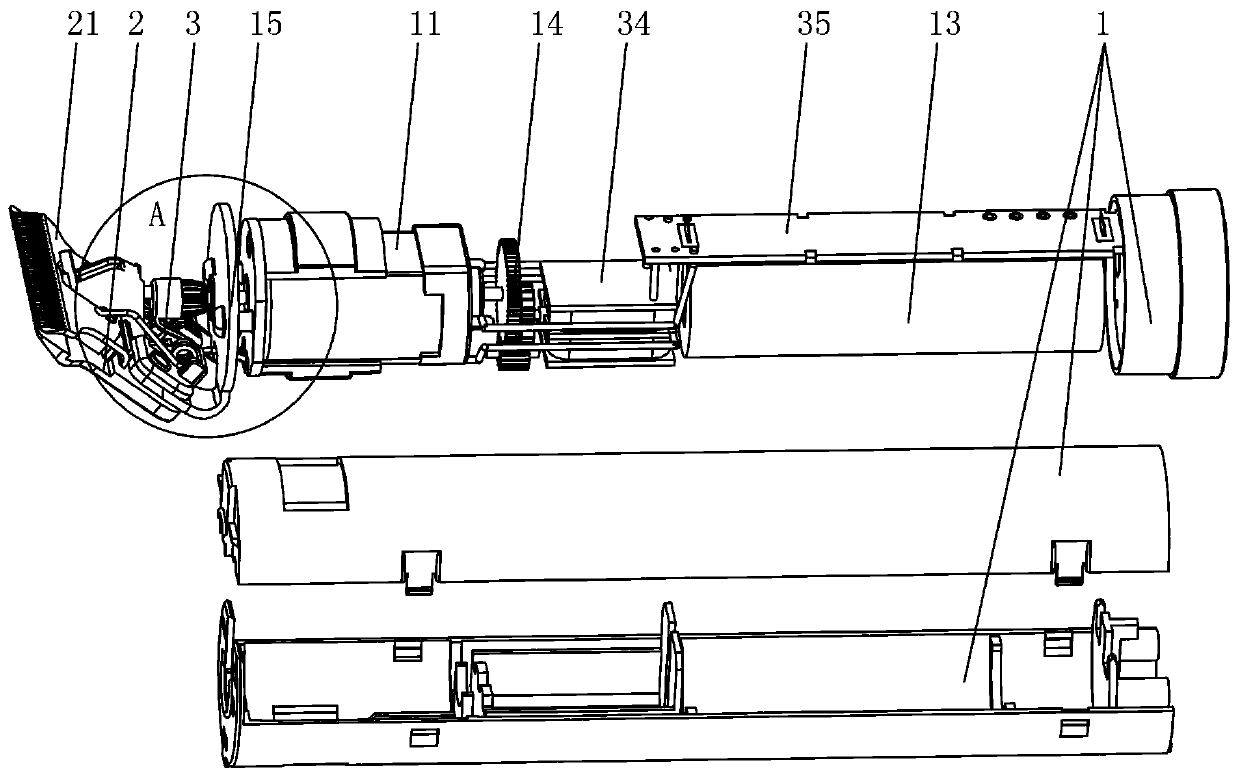

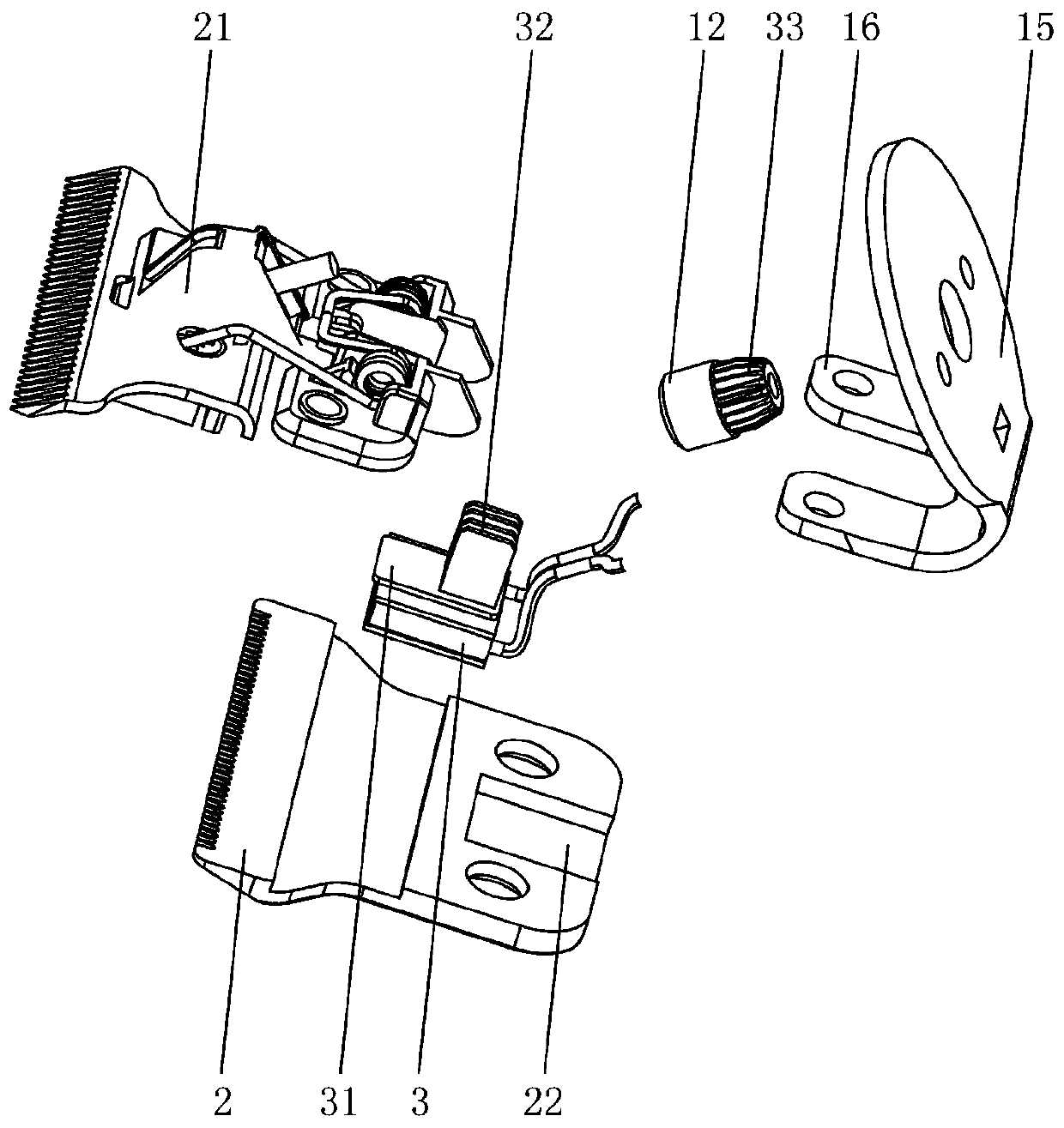

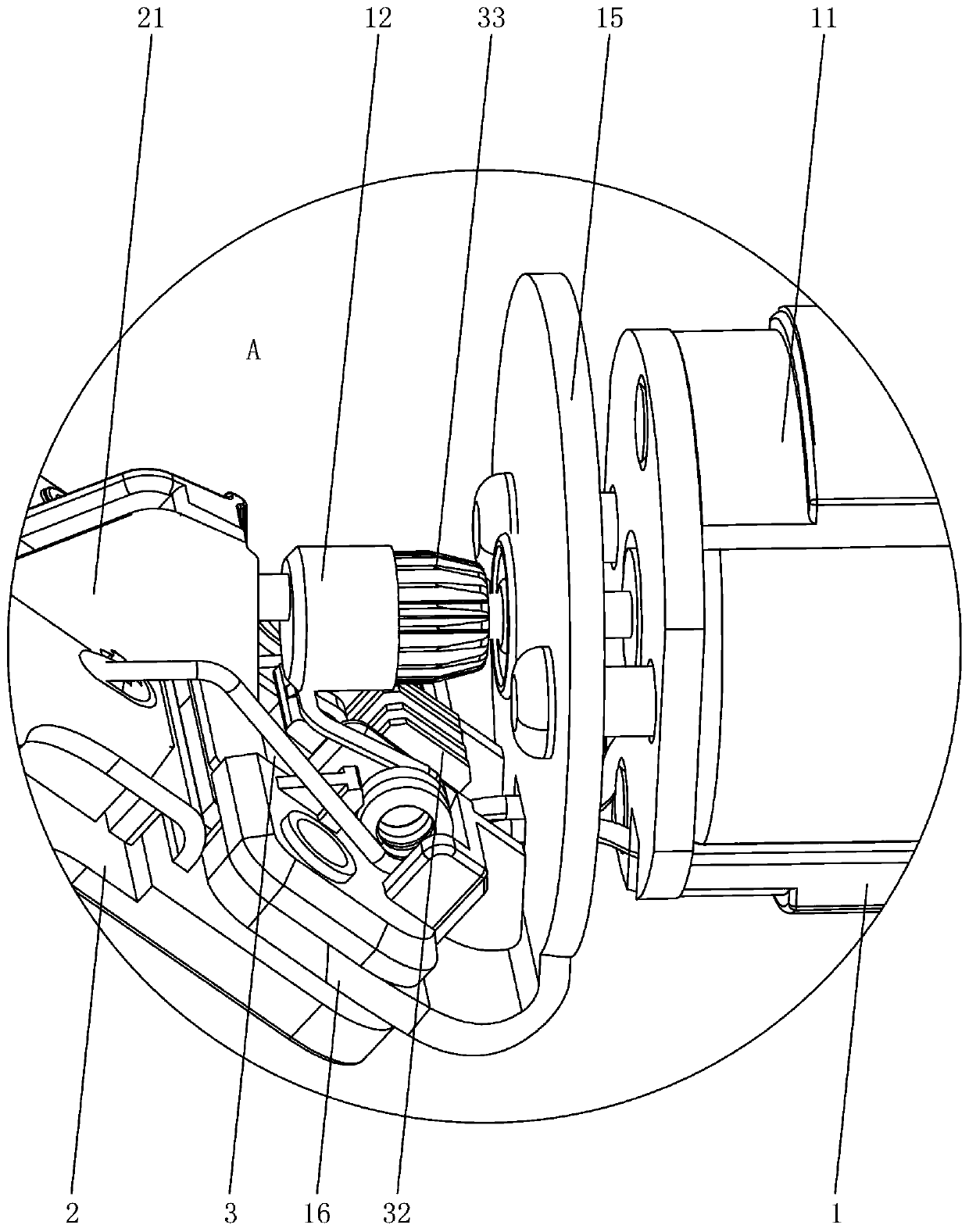

[0019] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0020] Such as Figure 1-3 As shown, a kind of electric clipper with refrigeration structure according to the present invention includes a body 1, the front end of the body 1 is provided with a fixed blade 2 and a moving knife assembly 21, and the fixed blade 2 is provided with a semiconductor refrigerator 3, The semiconductor cooler 3 is electrically connected to the body 1 through a circuit; the semiconductor cooler 3 can be reasonably matched according to the working and heating conditions of the electric clippers, and the semiconductor cooler 3 directly exchanges heat with the fixed blade 2 forcibly, which can effectively reduce the moving knife assembly 21. The working heat generated between the fixed blade 2 prevents the reduction of lubrication effect caused by overheating, the increase of wear and the situation of scalding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com