Solid wood original ecological weathering preparation method

A technology of original wood and solid wood, which is applied in the field of preparation of original ecological weathering of solid wood, can solve the problems of complex preparation process, high cost, and residual formaldehyde feel of solid wood products, and achieve the effects of increasing preparation cost, strengthening strength and prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

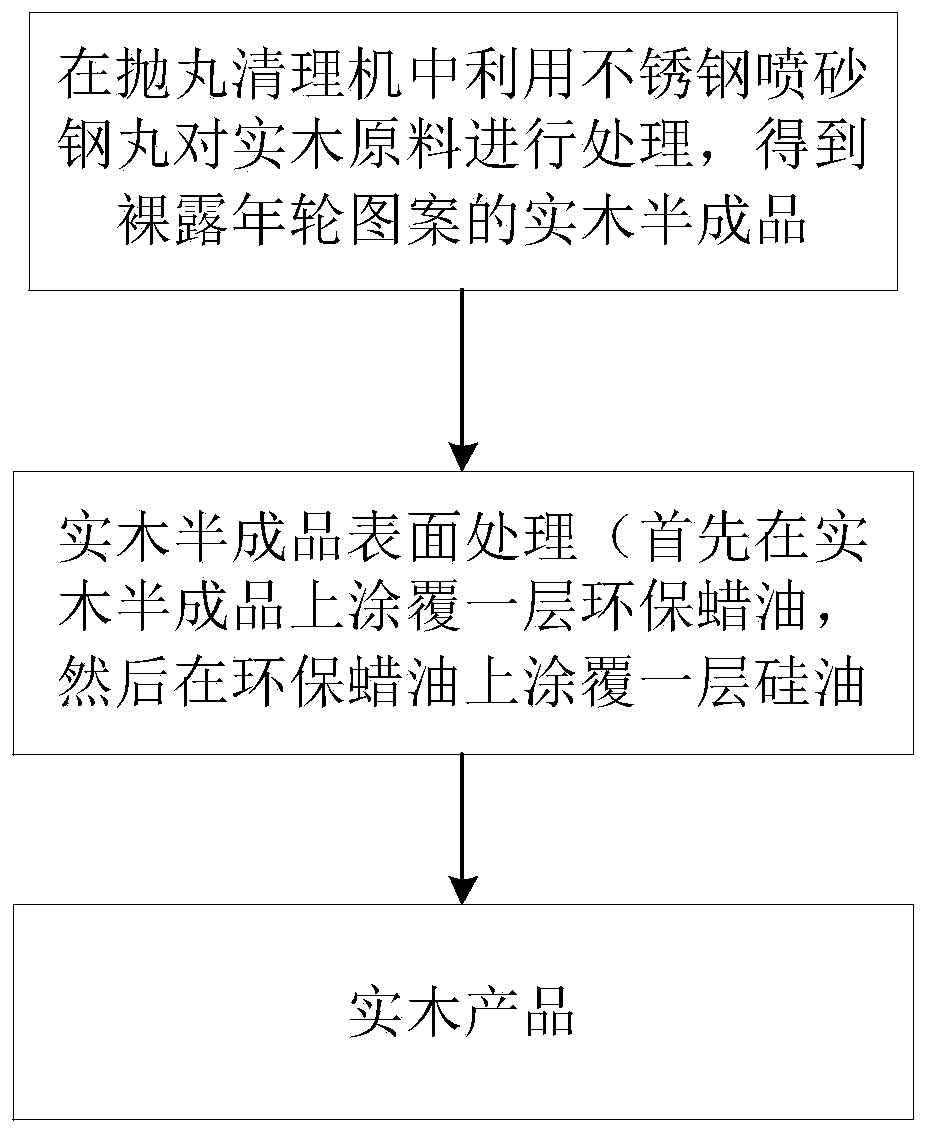

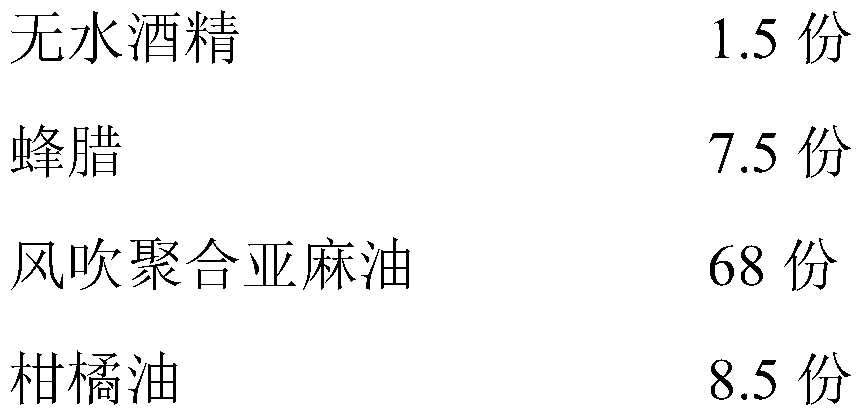

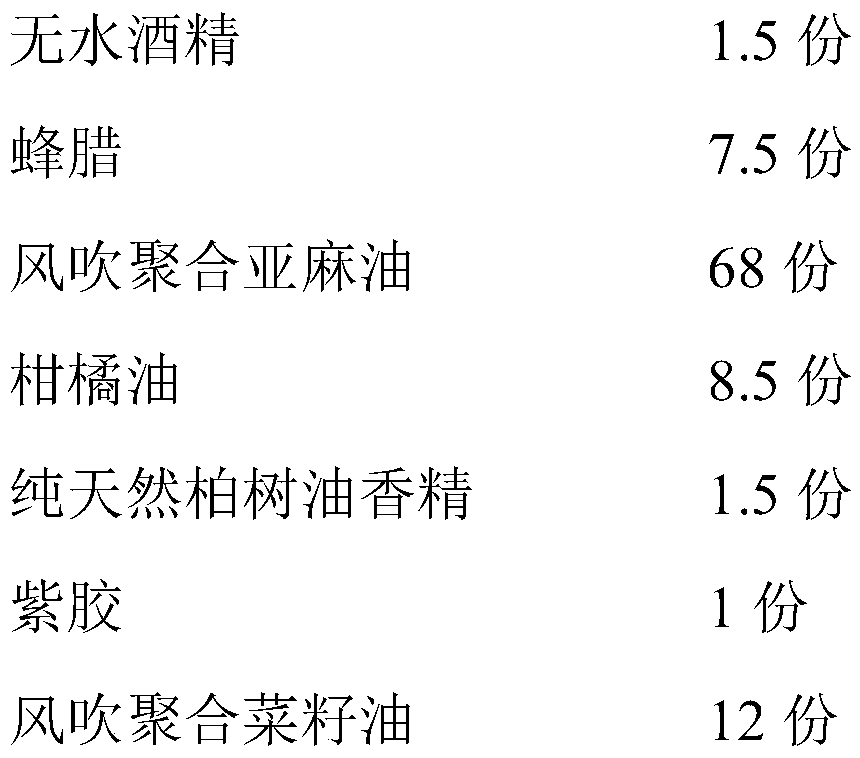

[0036] A preparation method for original ecological weathering of solid wood, comprising the following steps:

[0037]Step 1: Put the fragrant hardwood and stainless steel sandblasting steel shots into the shot blasting machine, and use the solid wood to produce a soft layer and a hard layer between the wood layer and the wood skin layer during the annual growth process of the solid wood. Woody layer, when the shot blasting machine processes the solid wood raw material, the stainless steel sandblasting steel shot digests the soft woody layer in the solid wood raw material while leaving the hard woody layer in the solid wood raw material, thereby removing the annual rings of the solid wood raw material Get bare and get a solid wood semi-finished product with a unique pattern. In addition, when the shot blasting machine processes the solid wood raw materials, the heat released by the heating phenomenon between the stainless steel sandblasting steel shot and the solid wood dries ...

Embodiment 2

[0043] The preparation of the original ecological weathering of solid wood was carried out according to Example 1. The difference was that the environmental protection wax oil coated on each square of solid wood was 110g, and the silicone oil coated on each square of solid wood was 55g.

Embodiment 3

[0045] The preparation of the original ecological weathering of solid wood is carried out according to Example 1, the difference is that the environmental protection wax oil coated on each square of solid wood is 100g, and the silicone oil coated on each square of solid wood is 50g.

[0046] In summary, the present invention solves the technical defects in the prior art. The purpose of the present invention is to solve the technical problem of using chemical solid wood for processing due to the antique weathering of solid wood products or the harm of chemical residues in solid wood to people. The combined use of steel shots can digest the soft wood layer in the solid wood while retaining the hard wood layer in the solid wood to realize the separation between the hard wood layer and the soft wood layer, thereby exposing the annual ring pattern of the solid wood , get a unique pattern, and get a solid wood product with excellent weathering effect, which not only avoids the harm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com