Graphene oxide/carboxylated styrene-butadiene rubber master batch as well as preparation method and application thereof

A technology of carboxylation and graphene, which is applied in the field of rubber materials, can solve the problems of weak interfacial bonding strength and poor dispersion of graphene, and achieve the effects of enhancing interfacial bonding force, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing graphene oxide / carboxylated rubber masterbatch, which includes: drying carboxylated rubber latex; adding graphene oxide (GO) to the dried carboxylated rubber latex for mixing, Get graphene oxide / carboxylated rubber masterbatch.

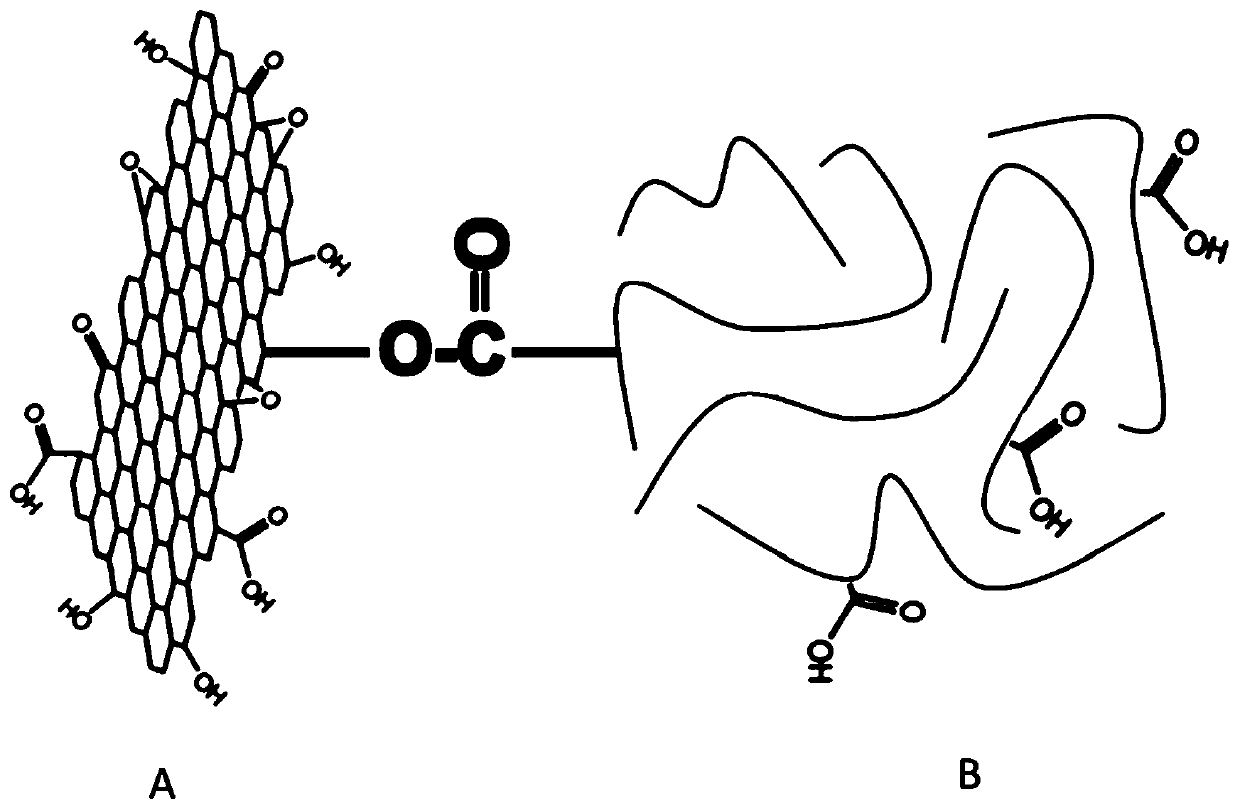

[0025] According to the present invention, for graphene / rubber composite materials, the dispersibility of graphene in rubber and the bonding strength of the interface between graphene and rubber polymer are two important fundamental factors that affect the final performance of the material. The inventor of the present invention found that adding graphene oxide / carboxylated rubber masterbatch during the preparation of graphene / rubber composites can effectively enhance the interface bonding force between graphene and rubber, which is beneficial to the dispersion of graphene in rubber.

[0026] specifically, figure 1 The schematic diagram of the mechanism of the graphene oxide / carboxylated rubber masterbat...

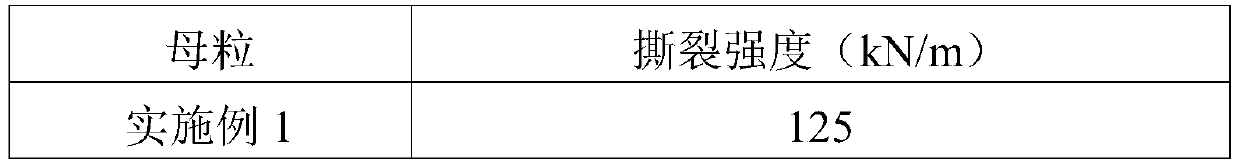

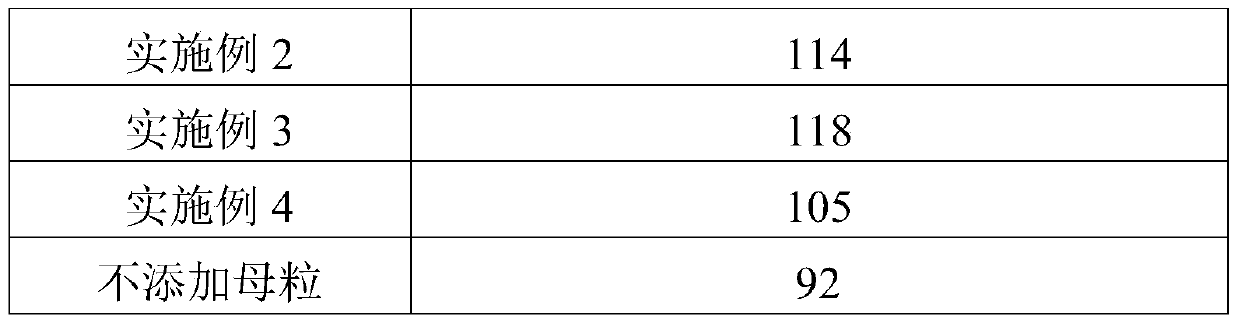

Embodiment 1

[0036] This embodiment is used to illustrate the preparation method of the graphene oxide / carboxylated rubber master batch of the present invention.

[0037] 1) In parts by weight, weigh 100 parts of carboxylated styrene butadiene rubber (Zionon, Japan), 5 parts of graphene oxide, 13 parts of carbon black, and 0.8 parts of antioxidant 4010NA.

[0038] 2) After the liquid carboxylated rubber latex and graphene oxide powder are ultrasonically dispersed, stirred uniformly, dried at 70°C, then mixed with carbon black and antioxidant 4010NA into an open mill for mixing to obtain graphene oxide / carboxyl Chemical rubber masterbatch.

Embodiment 2

[0040] This embodiment is used to illustrate the preparation method of the graphene oxide / carboxylated rubber master batch of the present invention.

[0041] 1) Weigh 100 parts of carboxylated styrene butadiene rubber (Taiwan Rubber and Plastics), 8 parts of graphene oxide, 18 parts of carbon black, and 1.6 parts of antioxidant RD in parts by weight.

[0042] 2) After the liquid carboxylated rubber latex and graphene oxide powder are ultrasonically dispersed, stirred uniformly, dried at 75°C, then mixed with carbon black and antioxidant RD and added to an open mill for mixing to obtain graphene oxide / Carboxylated rubber masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com